Fluorescent temperature sensor probe and manufacturing method thereof

A fluorescent temperature and sensor technology, applied in the field of fluorescent temperature sensor probes, can solve the problems that the sensor cannot measure the ambient temperature of the micro-area, the additional mass of the heat-sensitive area is large, and the measurement accuracy is affected, and achieves small size, simple manufacture and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

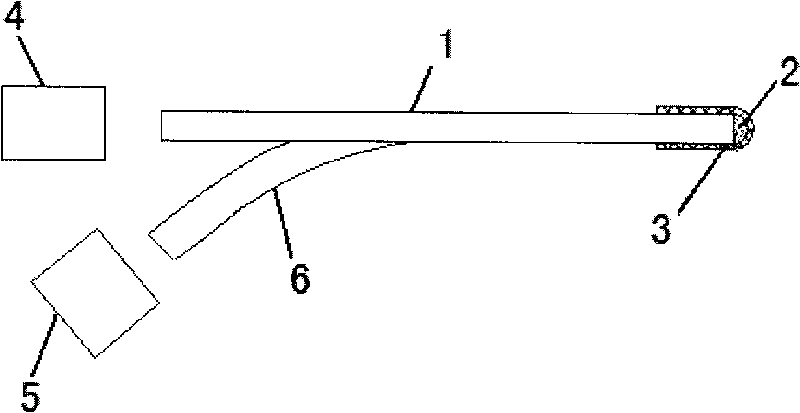

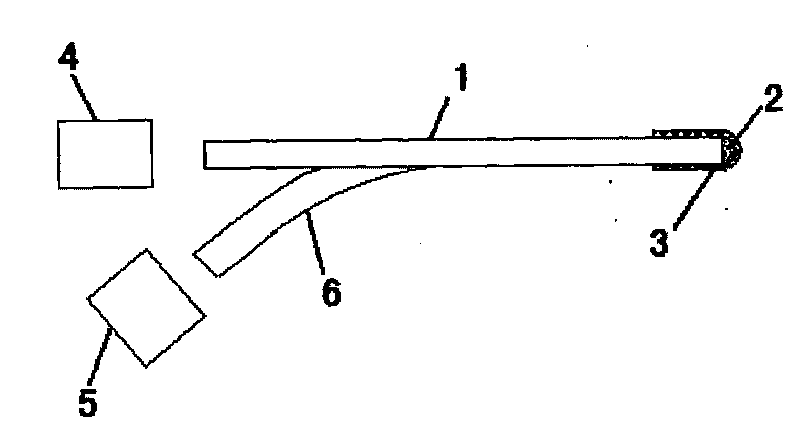

[0012] Such as figure 1 As shown, the temperature sensor is composed of a temperature-sensitive temperature sensor probe, a light source 4, a spectral measurement system 5 and a propagation optical path. The temperature sensor measures the temperature by using the fluorescence characteristics of the temperature-sensitive material that changes with temperature. Optical components such as isolators and polarizing components can also be added to the optical path of the system. Commonly used light sources 4 include mercury lamps and inert gas lamps, such as xenon lamps, deuterium lamps, semiconductor lasers, and tungsten-halogen lamps. According to the luminescent characteristics of fluorescent materials and the absorption characteristics of the excitation light waveguide 1, an excitation light source 4 with a suitable wavelength is selected and selected. A color filter with a suitable wavelength band. The typical propagation path adopts a Y-shaped optical waveguide. The excitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com