Range hood

A range hood and fume collecting hood technology, applied in the field of range hoods, can solve the problems of unsatisfactory grease separation effect, uneven air flow at the fan inlet, increased aerodynamic noise of the fan, etc., and achieves ingenious design, small resistance, and reduced The effect of flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

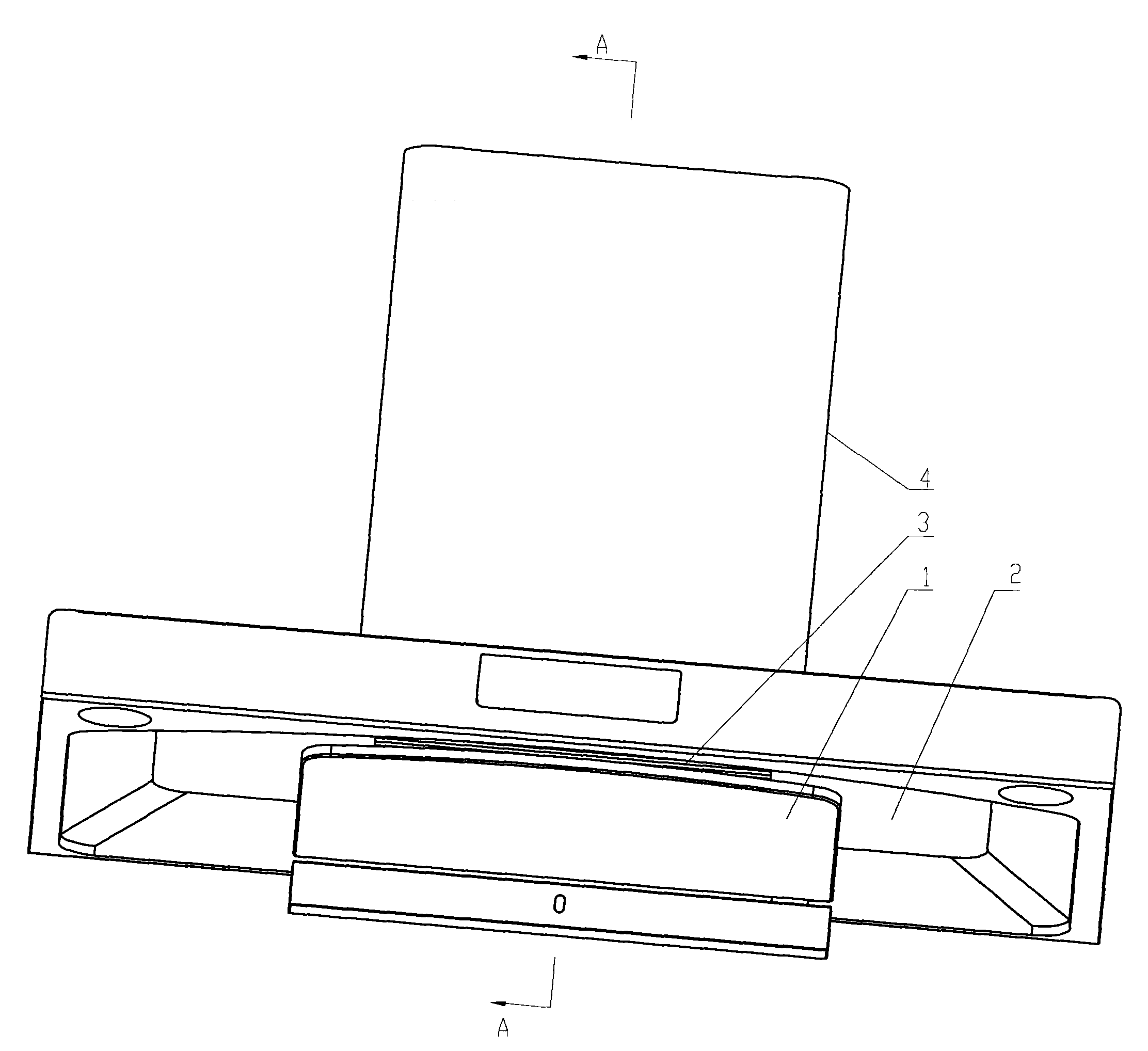

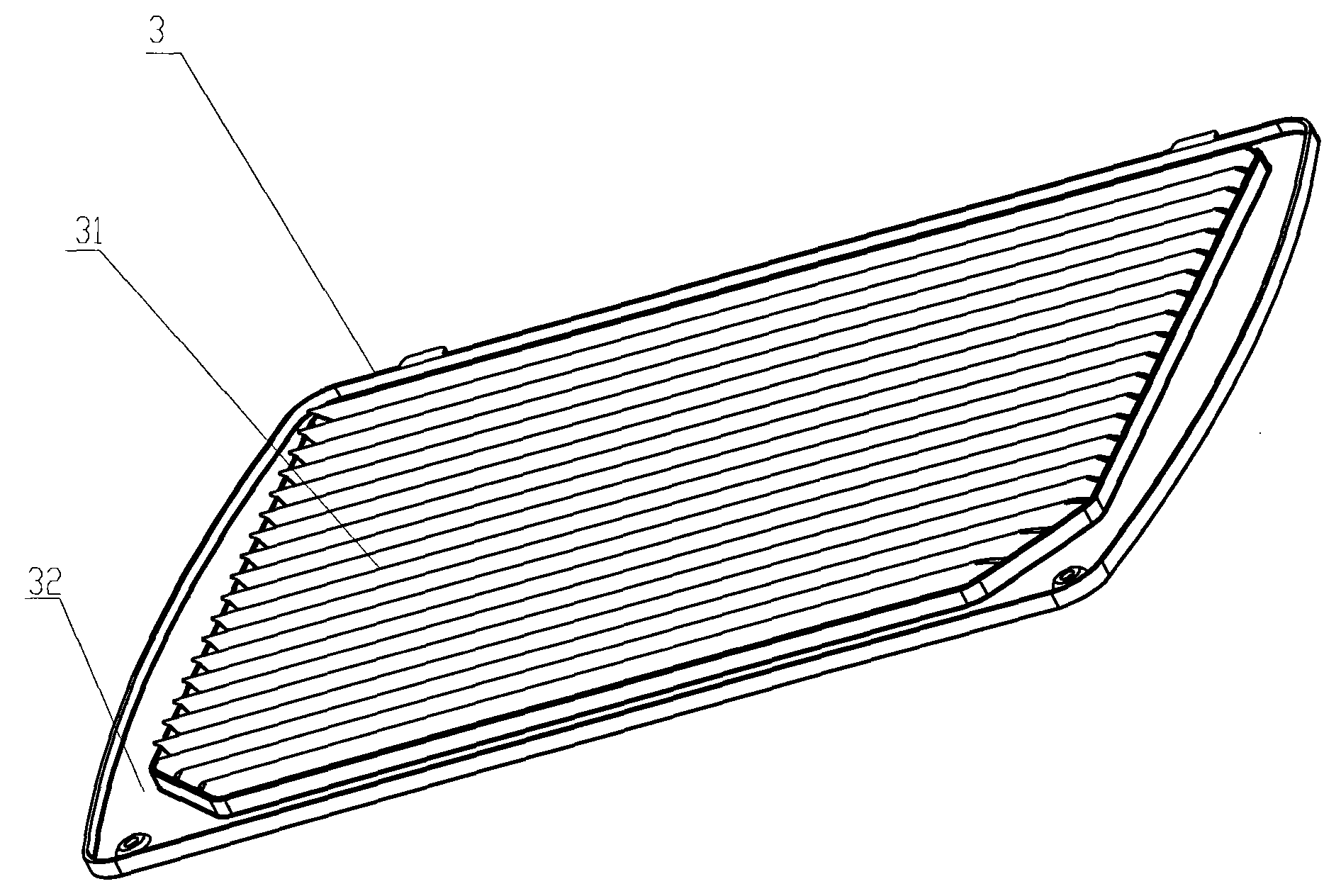

[0032] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the range hood of the present invention includes a smoke guide plate 1, a smoke collecting hood 2, a rectifying net 3 and a box body 4, wherein the smoke collecting cover 2 is provided with an air inlet 21, and the smoke guide plate 1 The air inlet 21 is set right, and a predetermined distance is kept from the fume collecting hood 2. The fan system 5 is arranged in the box 4 above the fume collecting hood 2, and a rectifying net is provided at the air inlet 21 of the fume collecting hood 2. 3. The rectifying net 3 is fixed on the air inlet 21 of the smoke collecting hood 2, wherein the rectifying net 3 includes a row of straight and long blades 31, and the straight and long blades 31 are arranged along the front and rear direction of the hood.

[0033] The cross-section of the above-mentioned straight long blades 31 is a plane in-line airfoil cascade, and the passage of the plane in-line airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com