Conduction state adjustment method of horizontal electroplating bath conducting roller and band steel

An adjustment method and a technology of conductive state, which is applied in the field of adjusting the conductive state of conductive rollers and strip steel in horizontal electroplating tanks, to achieve the effects of expanding the conductive area, improving product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

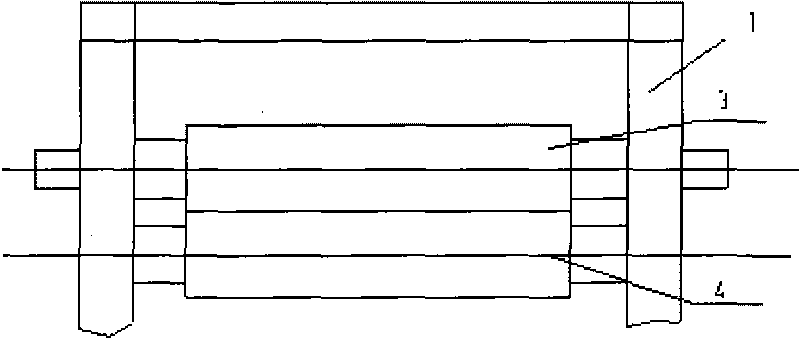

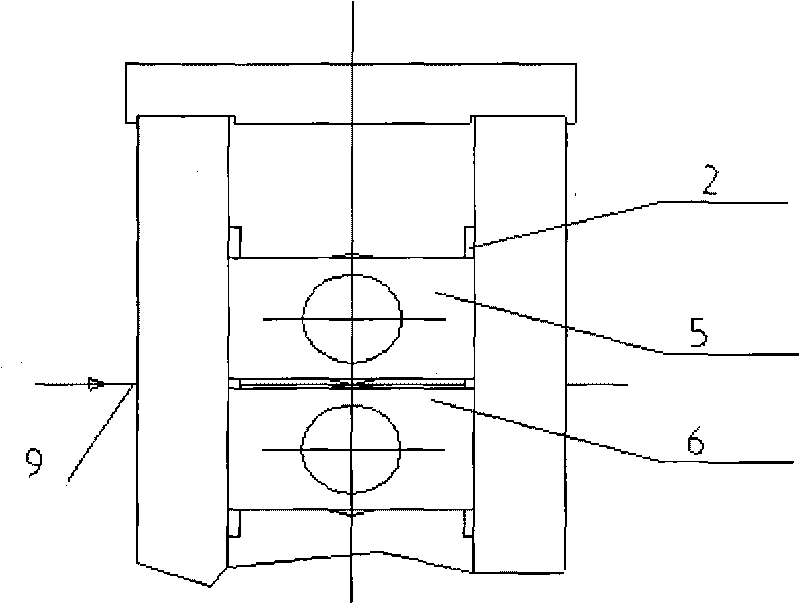

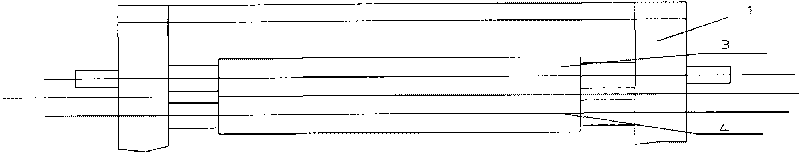

[0014] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. Such as Figure 3 ~ Figure 6 Shown: the device involved in the present invention includes: column 1, guide rail 2, conductive roller 3, backup roller 4, conductive roller bearing seat 5, backup roller bearing seat 6, backing plate 7, adjustment backing plate 8a, adjustment backing plate 8b. When there is a need for adjustment, you can press the set value ΔS of ΔS 设 , so that (the thickness of the adjustment backing plate 8a-the thickness of the adjustment backing plate 8b)=2ΔS 设 , the center of the back-up roller 4 moves along the opposite direction of the running of the strip steel 9, and the center of the conductive roller 3 is staggered by ΔS 设 . Now the conduction area between conductive roller 3 and strip steel 9 just can increase, and resistance reduces, and between plating tank outlet and conductive roller 3, the drift current in the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com