Method for extracting gasoline and diesel fuel and recovering clay from petrifaction waste clay

A waste clay, gasoline and diesel technology, applied in chemical instruments and methods, petroleum industry, separation methods, etc., can solve problems such as excavation and unscientific potential, and achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

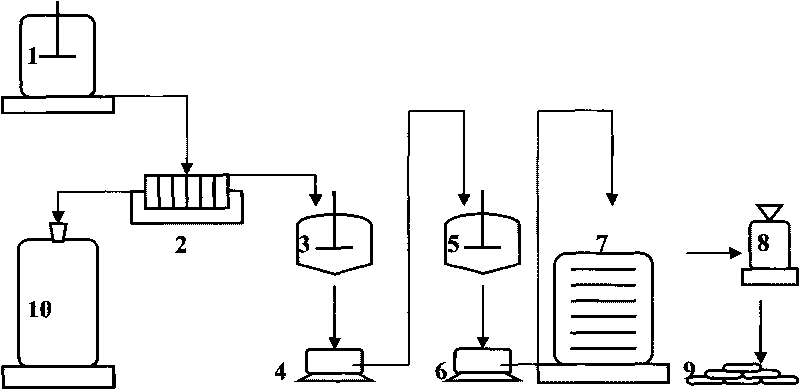

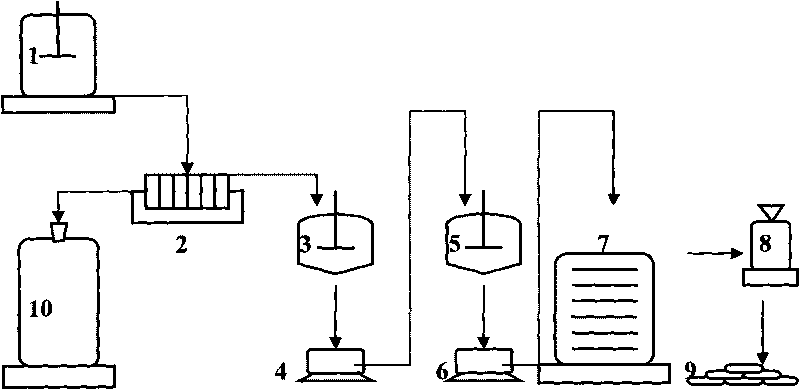

[0009] Embodiment 1: Clean petrochemical waste clay with an organic solvent and put it into the chemical cleaning tank (1) according to 1: 0.5-1.5, then stir it slowly for 5-20 minutes, and extract the oil in the clay by pressing and filtering (2) The product only has 5-10% organic solvent and a small amount of oil stain, and most of the oil product and organic solvent have entered the storage tank (10), and then stratified to obtain gasoline and diesel oil and organic solvent respectively. Drop into the saponification tank (3) with 20-30% sodium hydroxide solution and the above-mentioned press filter residue, persist in 20-30 minutes under uniform stirring and then dry the centrifuge (4) with 5-10% The steam (5) of the zinc chloride solution is boiled and activated for 50 minutes, and the regenerated activated clay (9) is newly obtained through drying (6), drying (7), and pulverization (8).

Embodiment 2

[0010] Embodiment 2: Clean the petrochemical clay with an organic solvent and put it into a chemical cleaning tank according to 1: 0.5-1.5, then slowly stir it for 5-20 minutes, and extract the oil in the clay with a squeeze filter method, leaving only 5-10 minutes. % of organic solvents and a small amount of oil, most of the oil and organic solvents have entered the storage tank, and then stratified to obtain gasoline and diesel oil and organic solvents. Use 20-30% sodium hydroxide solution and the above-mentioned press filter residue into the saponification tank, persist for 20-30 minutes under uniform stirring, then use a dry centrifuge, and then use 5-10% zinc chloride solution steam After boiling and activating for 50 minutes, regenerated activated clay is obtained by drying, drying and pulverizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com