Standardized controlling machine

A control machine and control information technology, applied in computer control, comprehensive factory control, electrical program control, etc., can solve the standardization obstacle of interpolation cycle, contour step size digital control system, poor reconfigurability, and no reconfigurability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

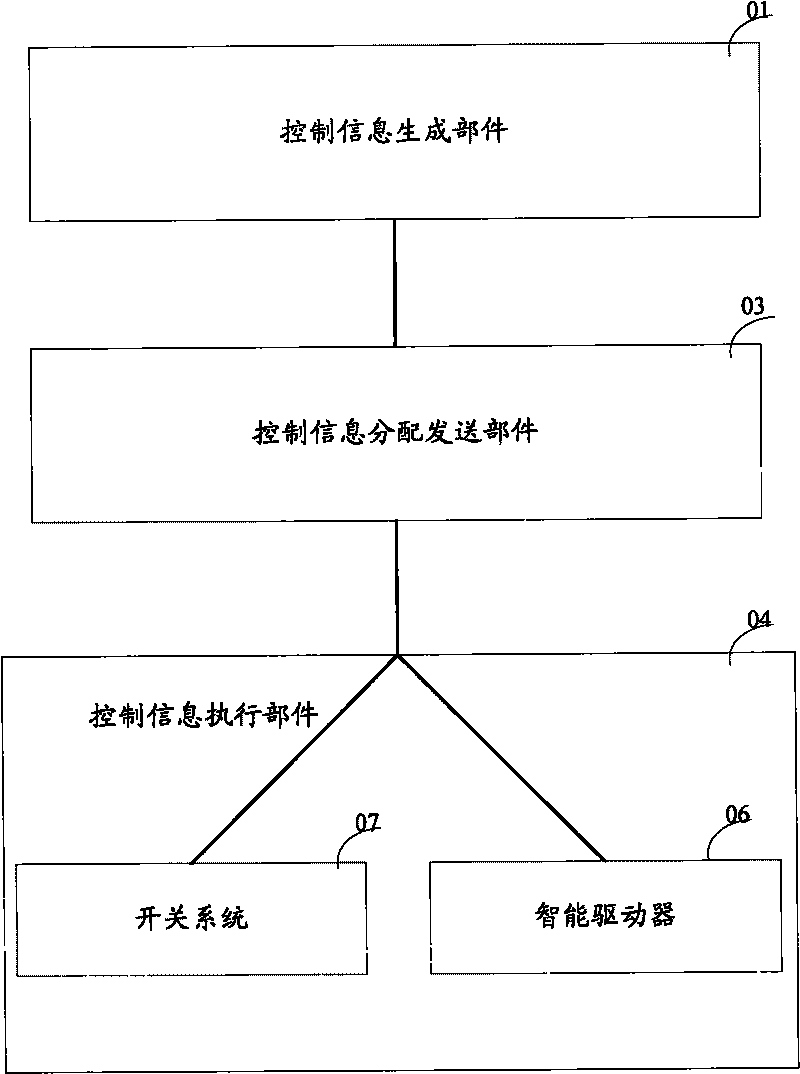

[0121] In this embodiment, an embodiment of a standardized DRC control machine is provided, such as figure 1 As shown, it consists of three types of functional components: control information generation component 01, control information distribution and transmission component 03, and control information execution component 04:

[0122] The control information includes a multi-axis associated data stream, a multi-parameter associated data stream, and a switch control stream; the multi-axis associated data stream controls the contour motion of the shaft in real time, the switch control stream controls the switch system in real time, and the multi-parameter associated The data stream controls the process parameters in real time; the control information is stored in the data control stream file, namely the DCFS file;

[0123] The control information generation component 01 transmits the DCFS file to the control information distribution sending component 03;

[0124] The control i...

specific Embodiment 2

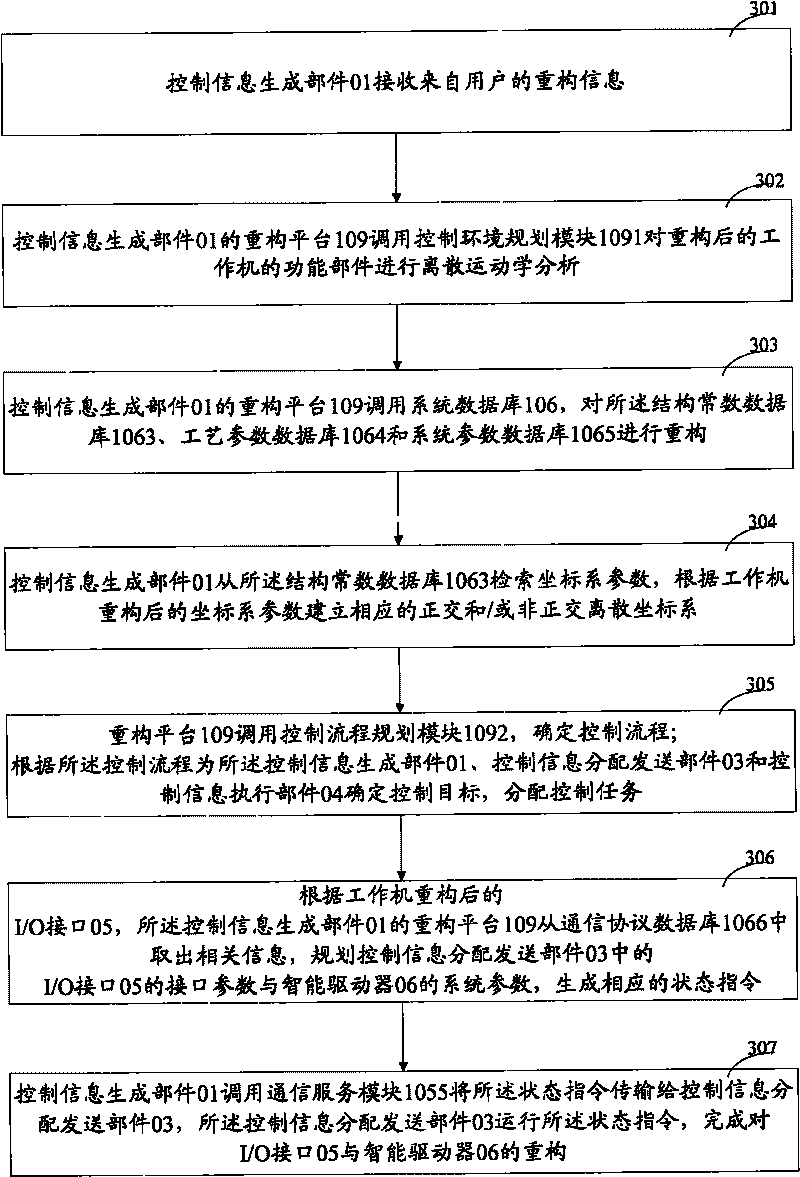

[0153] In this embodiment, a reconfiguration method and a stored information control method of the DRC control machine are proposed.

[0154] The reconfigurable manufacturing system has two basic requirements for the reconfigurable control system:

[0155] First, reconfigurable manufacturing systems require an all-round open digital control system. The control information generation unit 01 and the control information distribution sending unit 03 have the openness required by the reconfigurable manufacturing system.

[0156] Second, the modern digital control system constitutes a complex embedded system through the I / O system. The reconfigurable control system needs to change the I / O function in real time to adapt to different I / O systems, that is to say, the I / O system must be reconfigurable. A reconfigurable control system requires an open, reconfigurable I / O system.

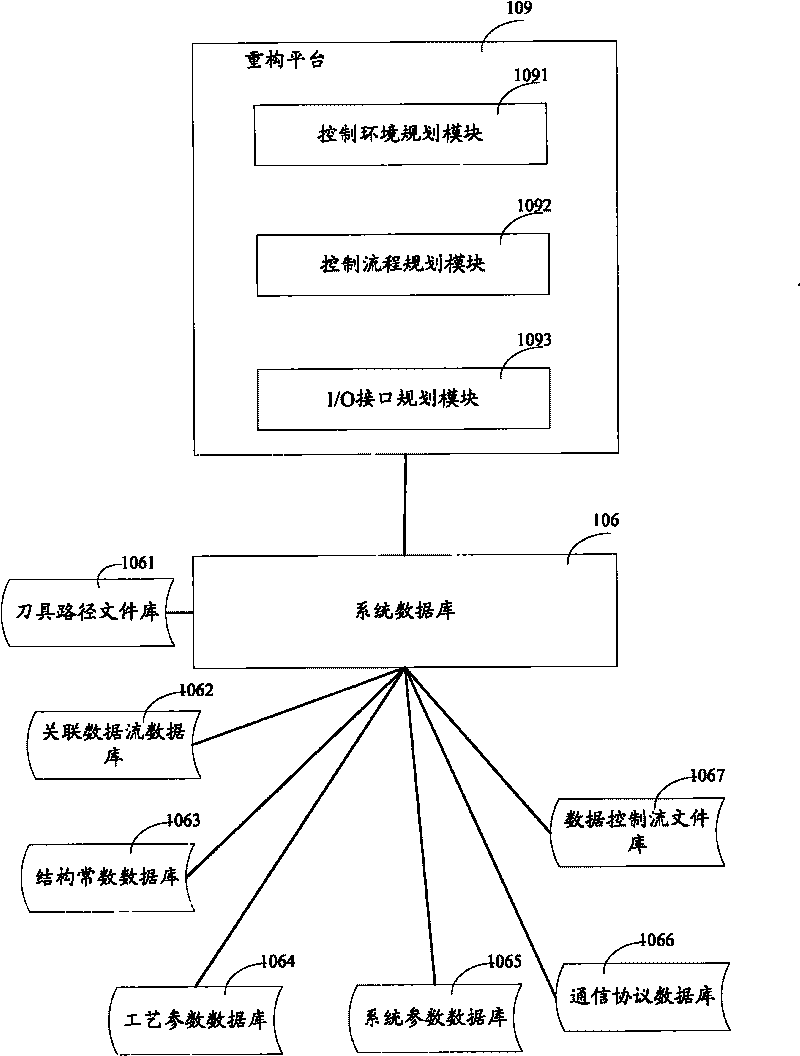

[0157] Based on the above requirements, such as Figure 4 As shown, the embodiment of the standardized ...

specific Embodiment 3

[0236] Figure 5 It is a schematic diagram of the architecture of the DRC control machine in this preferred embodiment.

[0237] The control information generation part 01 is connected with the control information distribution sending part 03 through the system bus (for example, Compact PCI or PCI—PCI bridge), that is to say, the control information distribution sending part 03 is integrated in the PC, in contrast to the soft open mode . What adopted is industrial PC. Obviously, this preferred implementation can complete all the control tasks that the soft open mode can accomplish, but overcomes the defects of the soft open mode, and has beneficial effects that the soft open mode does not have.

[0238] In the above specific implementation, the reconfigurable machine tool is used as the working machine, and the architecture of the DRC control machine and the storage information control method and reconfiguration method of the DRC control machine are described in detail. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com