Liquid crystal display panel and manufacturing method thereof

A technology for liquid crystal display panels and manufacturing methods, applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems of height difference between the peripheral area of the panel and the central area of the panel, uneven display of peripheral images, and different gaps between liquid crystal display panels, etc., to achieve The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

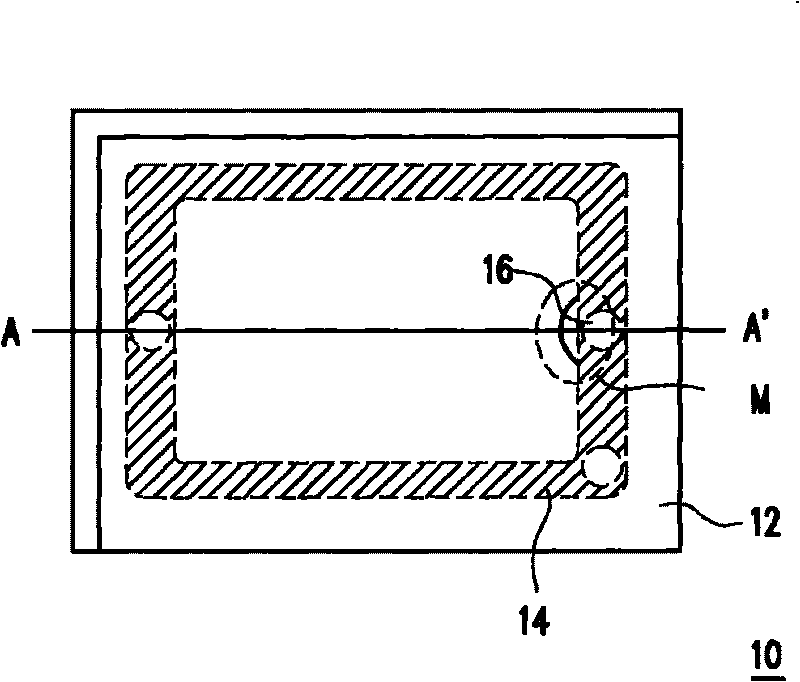

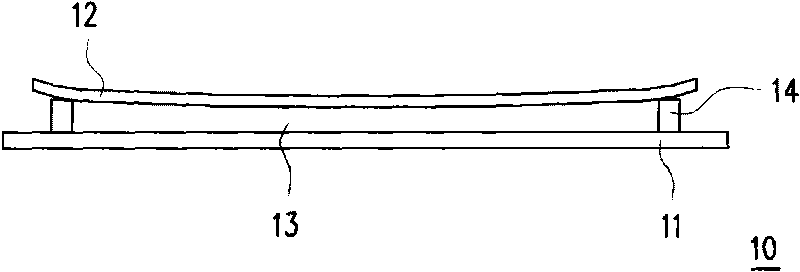

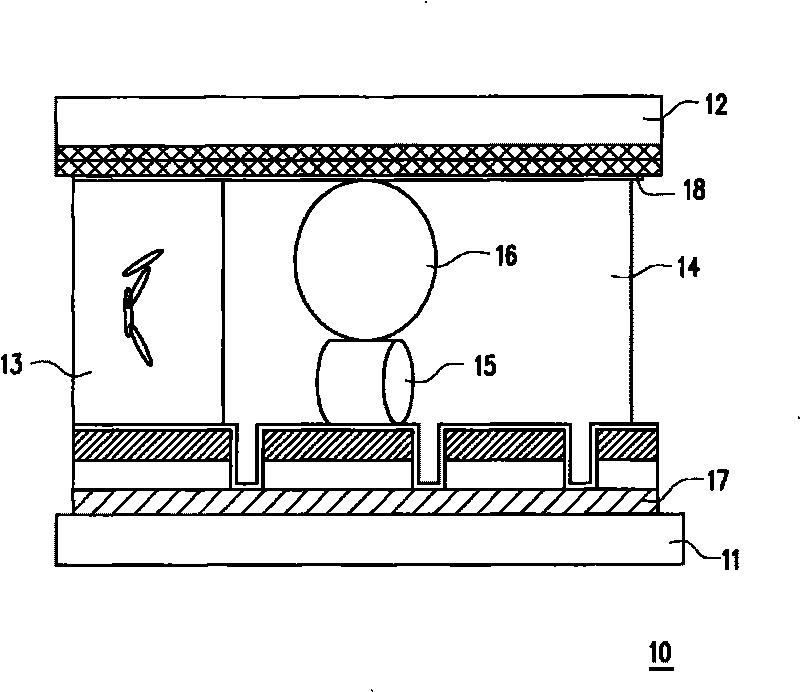

[0039] Figure 4A It is a partial cross-sectional enlarged view of the sealant 34 area of the liquid crystal display panel in the first embodiment of the present invention. see Figure 4A The liquid crystal display panel 20 has a display area 21 and a peripheral area 22 located on the periphery of the display area 21, and the liquid crystal display panel 20 includes a first substrate 31, a second substrate 32, a liquid crystal layer 33, and a sealant 34, wherein the first substrate 31 and The second substrate 32 is, for example, a thin film transistor substrate and a color filter substrate, respectively. The first substrate 31 and the second substrate 32 are arranged opposite to each other at a certain substrate distance D0, the liquid crystal layer 33 is arranged between the first substrate 31 and the second substrate 32, and the sealant 34 is sandwiched between the first substrate 31 and the second substrate 32 Between, around the liquid crystal layer 33 to surround and ...

no. 2 example

[0060] Figure 6 It is a partial cross-sectional enlarged view of the frame glue area of the liquid crystal display panel according to the second embodiment of the present invention. Please refer to Figure 6 The liquid crystal display panel 30 of the second embodiment is similar to the first embodiment, except that on the second substrate 32 of the liquid crystal display panel 30 of the present embodiment, the black matrix 41 further provides a second contact hole H2, and the common electrode 42 covers the black The matrix 41 extends to the inner surface of the second contact hole H2 , and the common electrode 42 in the second contact hole H2 is connected to the contact electrode 39 in the first contact hole H1 through the conductive particles 40 .

[0061] Furthermore, the opening position of the second contact hole H2 of the black matrix 41 is set relative to the position of the first contact hole H1. As described in the first embodiment, the diameter and depth of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com