Device for measuring flux density value of practical air gap field of magnetic steel in electric appliance

An air-gap magnetic field and magnetic flux density technology is applied in the field of devices for measuring the actual air-gap magnetic flux density value of magnetic steel in electrical appliances. Strong and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

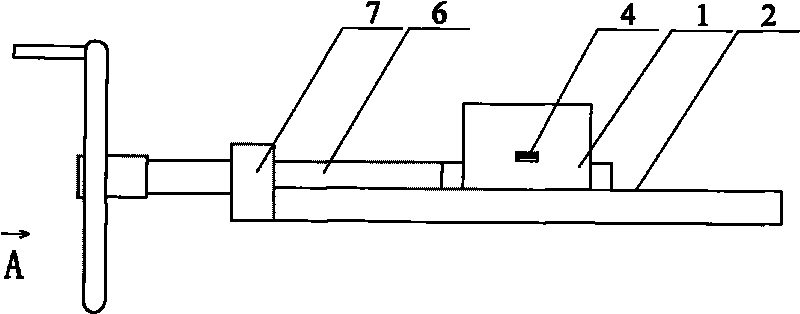

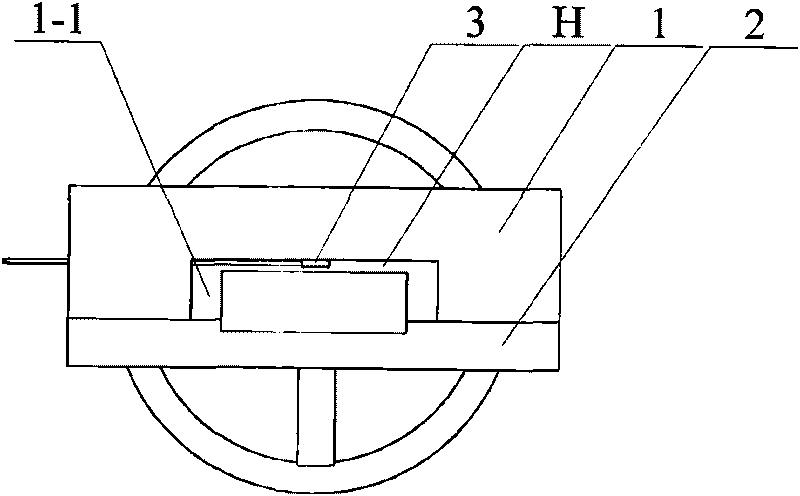

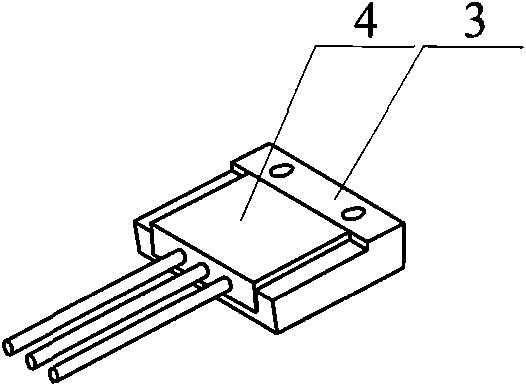

[0007] Specific implementation mode one: combine figure 1 , figure 2 with Figure 4 The device for measuring the actual air-gap magnetic flux density value of the magnetic steel in the electrical appliance is described in this embodiment, it includes a magnetic sensor 4, and it also includes a component for constructing the air-gap magnetic field, which is used for constructing the air-gap magnetic field The component is made of ferromagnetic material. The middle part of the component used to construct the air gap magnetic field has a channel 1-1 suitable for the size of the magnetic steel to be tested. The magnetic sensor 4 with the signal line interface is fixed on the channel 1-1. In the middle of the inner upper side wall, there is an air gap H between the upper inner side wall of channel 1-1 and the upper end surface of the magnet to be tested. The size of the air gap H is the same as the actual air gap of the magnet to be tested in the electrical appliance consistent....

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with figure 2 The device for measuring the actual air-gap magnetic flux density value of the magnetic steel in the electrical appliance is described in this embodiment, it also includes a magnetic induction detector 8, and the magnetic induction detector 8 communicates with the signal on the magnetic sensor 4 through the signal line line interface connection. The magnetic induction intensity detector 8 can quantitatively calculate the air-gap magnetic flux density value of the measured magnetic steel under the closed magnetic circuit condition, that is, the actual air-gap magnetic flux density of the electrical appliance. Embodiment 1 is the same.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 Describe the device for measuring the actual air-gap magnetic flux density value of the magnetic steel in the electrical appliance in this embodiment. The size of the air gap H is 0.4 mm to 3 mm. The other components and connections of this embodiment are the same as those in the specific embodiment One or two the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com