Device for measuring large-scaled bulb tubular hydraulic generator rotor

A water turbine generator, light bulb through-flow technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of high labor intensity, accuracy error, time-consuming efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

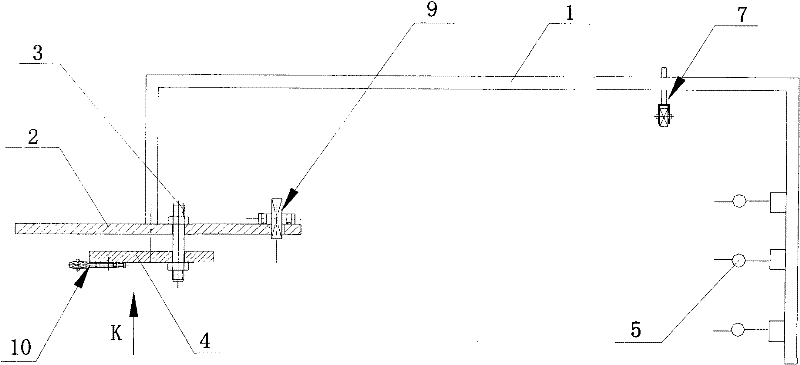

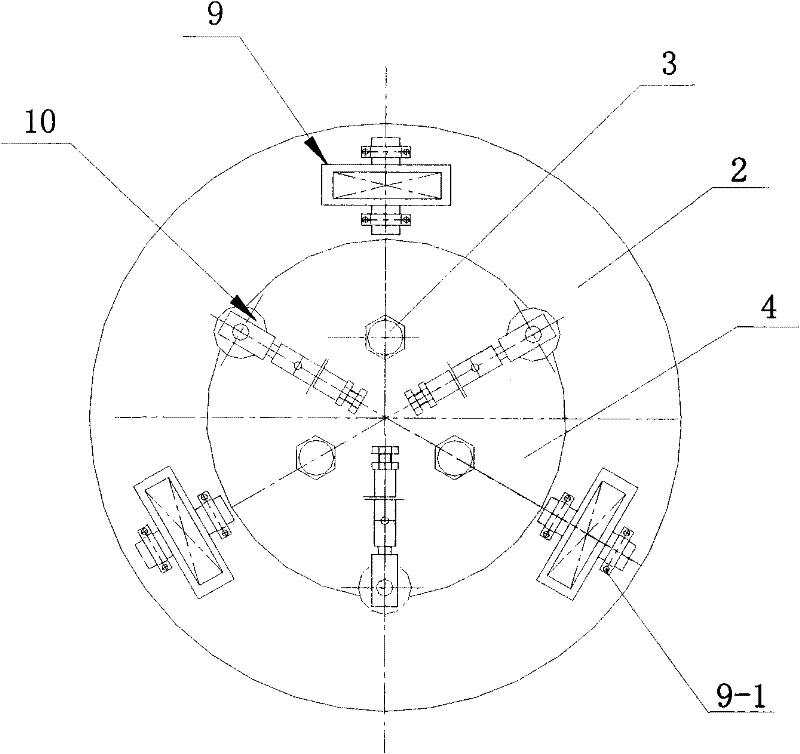

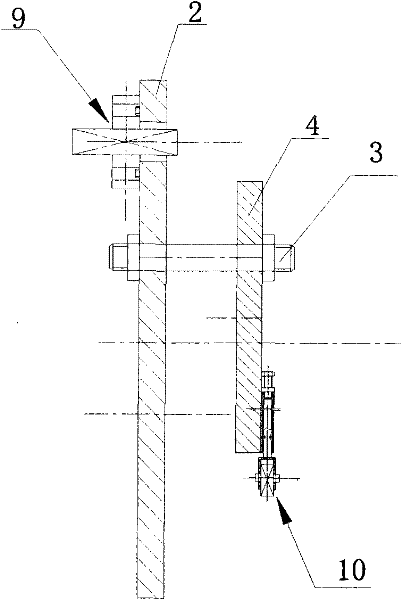

[0023] Example: see Figure 1 to Figure 3 , a rotor measuring device for a large bulb tubular hydroelectric generator, the patented measuring device includes a П-shaped rotor measuring frame 1, an upper turntable 2 connected to the left side of the rotor measuring frame 1, and the upper turntable 2 passes through fasteners The connecting bolt 3 connects the lower turntable 4 which is located on the lower side of the upper turntable 2 and is installed parallel to the upper turntable 2. On the inner wall on the right side of the rotor measuring frame 1, several dial gauges 5 for measuring magnetic poles are installed, and the hands of the dial gauge 5 extend to the magnetic poles. 6; the inside of the top of the rotor measuring frame 1 is provided with a bearing device 7, the bearing device 7 fits with the hub 8-1 of the rotor bracket 8, please refer to Figure 4 and Figure 5 , the bearing device 7 includes a bearing seat 7-1 bent into a П shape, a screw rod 7-2 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com