Foaming tool

A tool and valve core technology, applied in the field of foaming tools, can solve the problems of leaking foam sealant, foam filler, wear or loosening or deformation of sealing rings, shortening the service life of foaming tools, etc., so as to improve wear resistance, Long service life, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

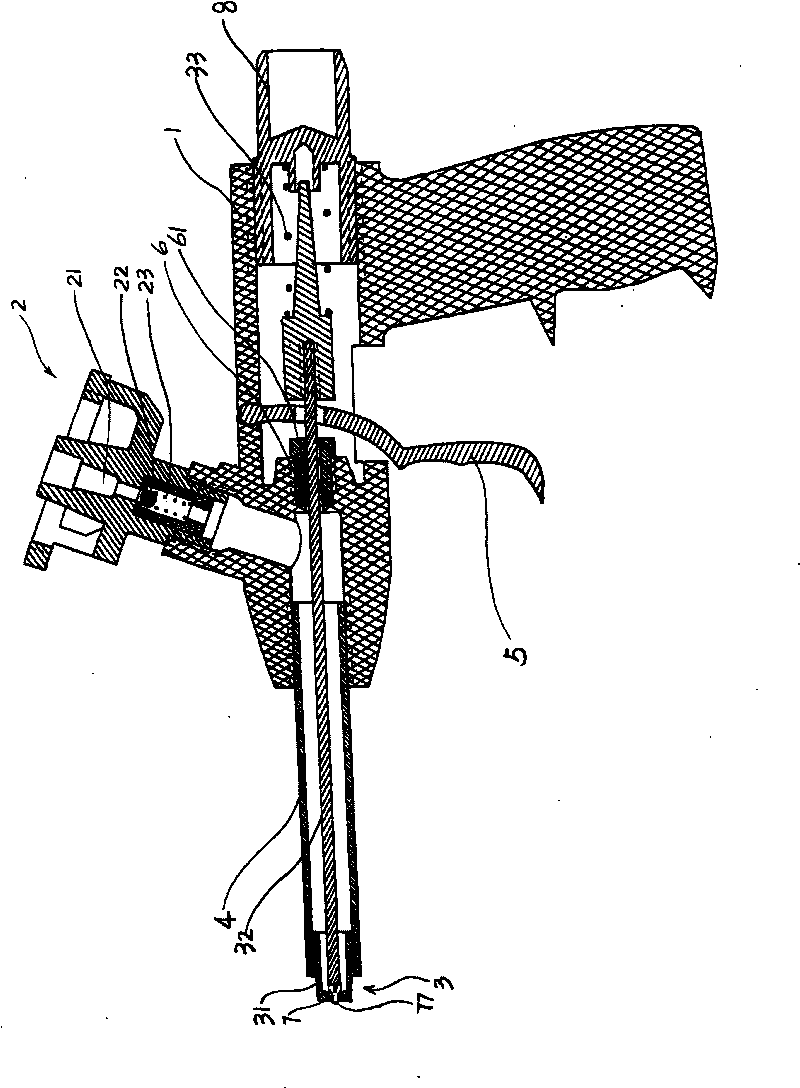

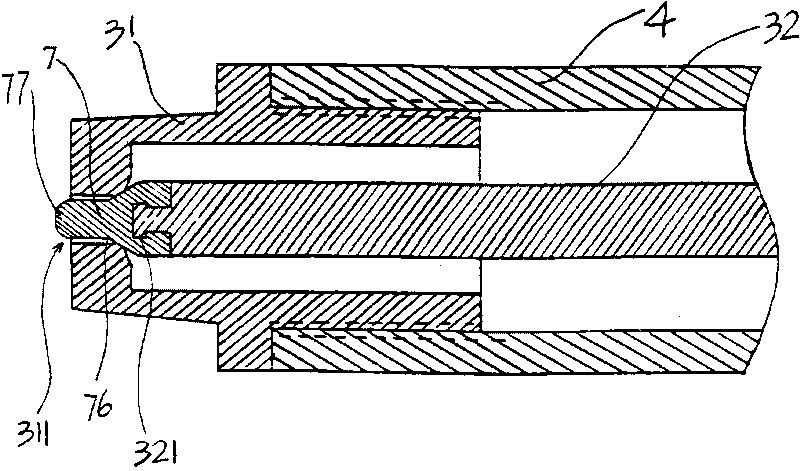

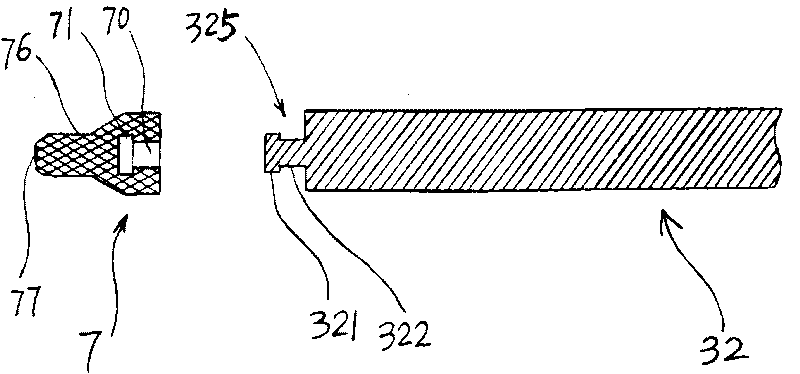

[0039]A foaming tool of the present invention, referring to all accompanying drawings, includes a gun body 1, a liquid inlet valve 2, a liquid outlet valve 3, a liquid outlet channel 4 and a switch device 5, and the liquid outlet valve 3 includes an outlet valve with an outlet 311 Liquid nozzle 31, spool 32 and back-moving spring 33, switch device 5 can make liquid outlet valve 3 open or close, for example, spool 32 has at least partly stretched out the internal channel of foaming tool, makes switch device 5 can directly or indirectly Acting on the spool 32 to make the spool 32 move, the head of the spool 32 is provided with a shoulder 325, and the shoulder 325 is provided with a convex portion 321 or a concave portion 322 or a thread 323, and also includes a plastic The seal 7 made, the plastic seal 7 is at least partly connected with the convex part 321 or the concave part 322 or the screw thread 323 provided on the shoulder 325 of the head of the valve core 32. The valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com