Method for collecting and treating excess sulphur and elemental carbon from process gas of carbon bisulfide production

A carbon disulfide and treatment method technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as process pipeline blockage, and achieve the effects of prolonging service life, reducing construction costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

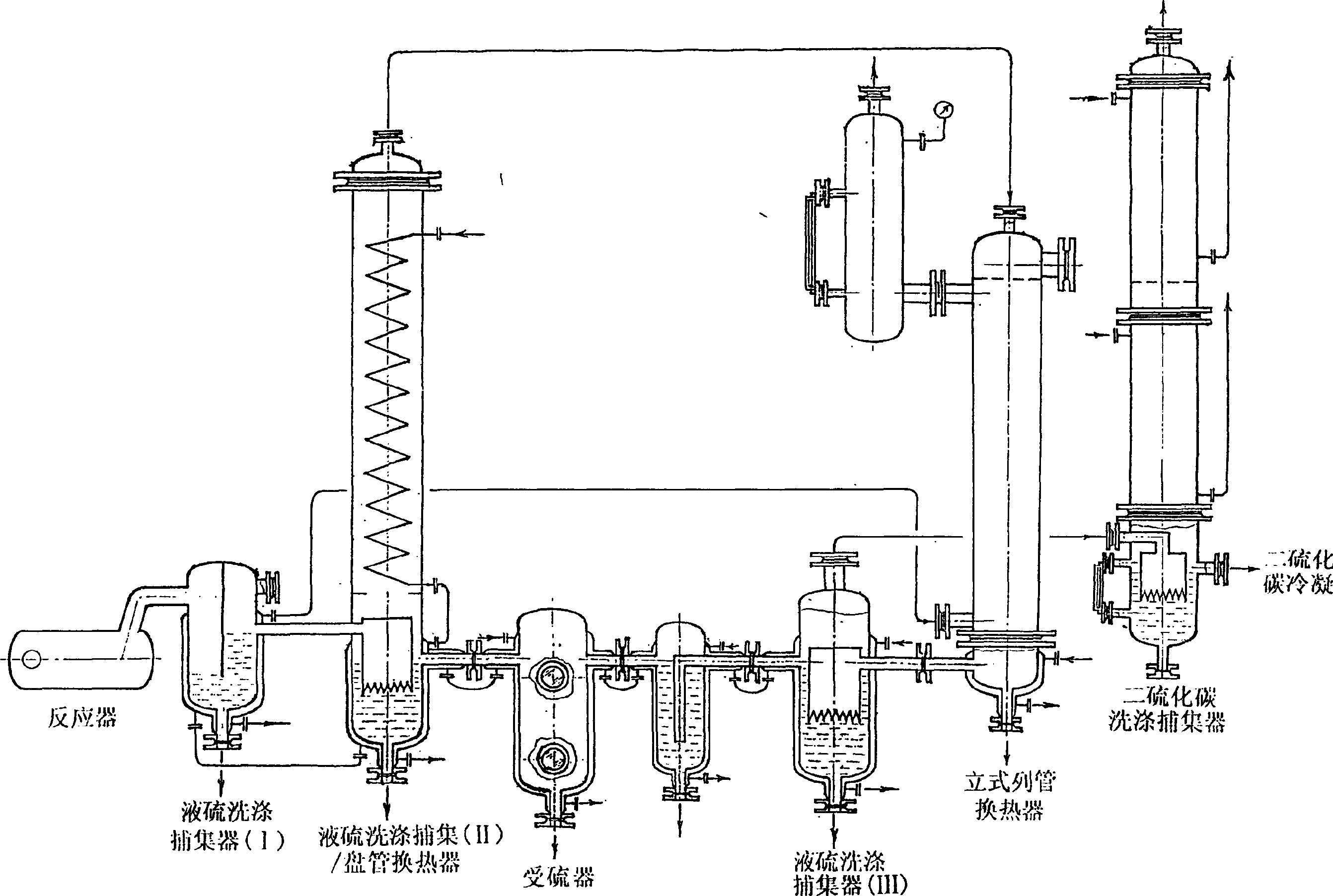

[0021] As shown in the figure is a process flow of the present invention for capturing and treating excess sulfur and elemental carbon in carbon disulfide production process gas. The process is as follows:

[0022]Using natural gas with an amount of 282 standard cubic meters per hour (composed of 96.37% methane, 1.62% ethane, 0.45% propane, and 33% 0-butane), and sulfur exceeding 6% of the theoretical amount as raw materials, at 640°C to 680°C After completing the reaction to synthesize carbon disulfide under the condition of 0.4Mpa, the process gas in the form of a mixture leaving the carbon disulfide reactor is washed and collected once by liquid sulfur at a temperature of 120°C-170°C, especially 120°C-150°C. The above-mentioned patent is used for washing. The application number is 02276560.3 industrial gas scrubbing equipment, and the process gas is carried out through the liquid scrubbing medium through the lower end of the partition structure extending into the liquid scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com