Clamping device of optical detector

An optical detector and clamping device technology, used in measuring devices, scientific instruments, material analysis by optical means, etc., can solve the problem that the clamping device cannot contact the PCB board, cannot contact the PCB board, and the central deformation of the PCB board and other problems, to achieve the effect of not easy to deform, improve positioning accuracy, and avoid skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

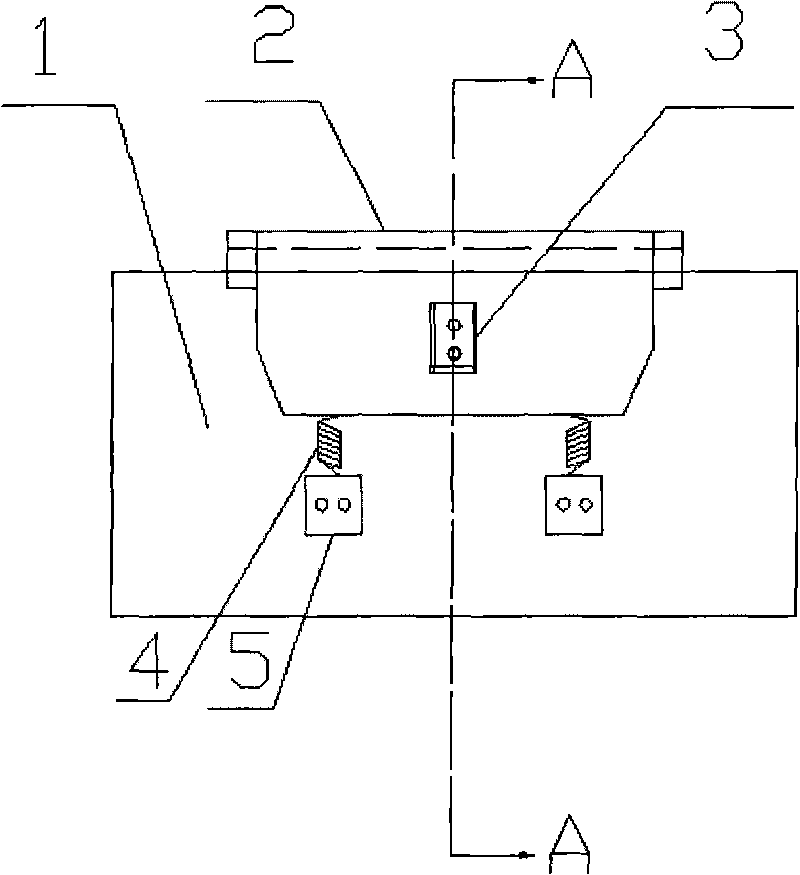

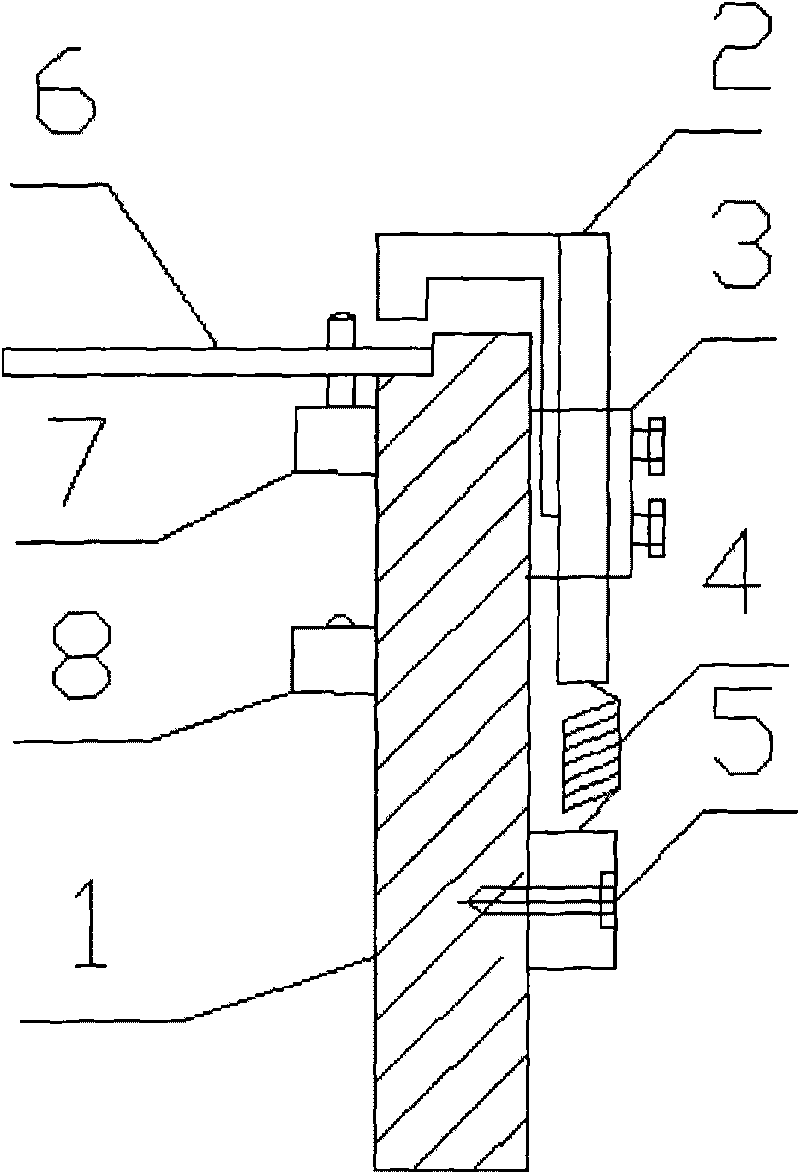

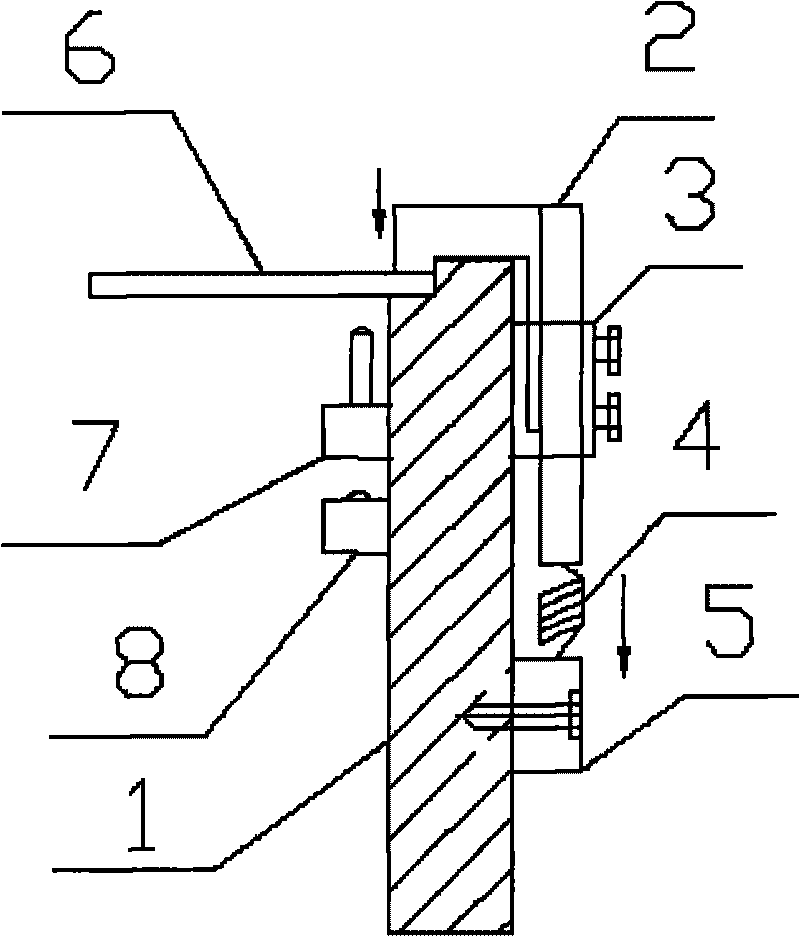

[0015] Such as figure 1 As shown, the clamping device of the optical detector of the present invention is mainly a kind of clamping device of the optical detector, comprising a clamp body 1, a clamp plate 2 positioned on the clamp body 1, a cylinder 3 on the clamp plate 2 and a clamp body located on the clamp body 1. The baffle plate 7 and the inductor 8 on the concrete 1, the top of the clamp body 1 is stepped, and the clamp plate 2 is an inverted "L" shape that matches the top of the clamp body 1, and is in contact with the top and one side of the clamp body 1. touch.

[0016] The bottom of the clamp plate 2 is connected with the spring seat 5 on the clamp body 1 through the spring 4 . When the air cylinder is inflated to drive the fixture plate to move downward to compress the workpiece, the stretching performance of the spring plays a buffer role in the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com