Device and method for measuring hardness of cigarettes and filter sticks

A technology of measuring device and measuring method, which is applied in the field of measurement, can solve problems such as the difference in test results, the inability to accurately check the magnitude of applied pressure, and the inability to adjust the error of applied pressure, so as to achieve good stability and consistency, and ensure no impact , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

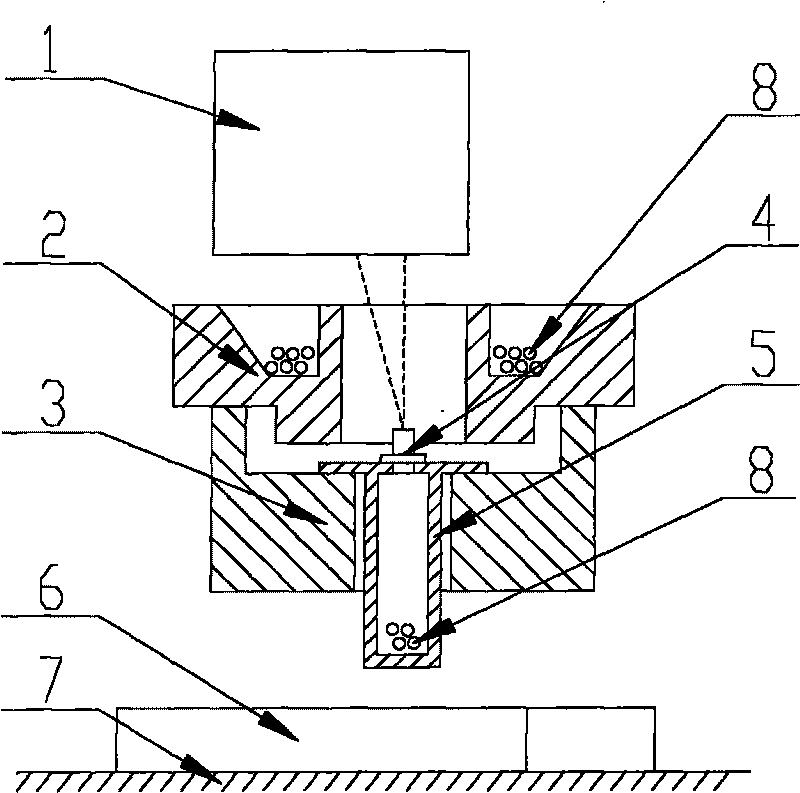

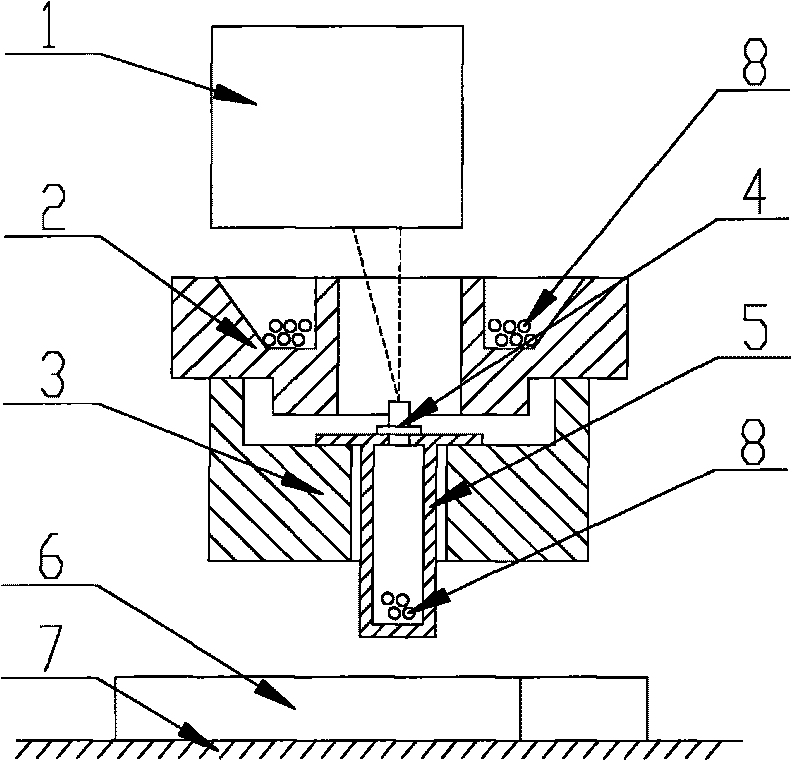

[0025] The cigarette, filter stick hardness measuring device and method thereof proposed by the present invention are described as follows in conjunction with the accompanying drawings and embodiments.

[0026] figure 1 Shown is a cross-sectional view of an embodiment of the cigarette and filter stick hardness measuring device according to the present invention. It can be seen from the figure that the device of this embodiment includes a high-precision laser displacement measuring head 1, an air bearing pressure applying mechanism and a control unit (not shown). The high-precision laser displacement measuring head 1 is used to measure the respective position data of the air bearing pressure applying mechanism under the state of applying pre-pressure and full pressure to the sample to be tested; the control unit is used to control the pressure of the air bearing The mechanism moves up and down to perform preload or full press operation.

[0027] Wherein, the air flotation pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com