Self-lubricating polypropylene compound material for manufacturing medical injectors

A self-lubricating, composite material technology, applied in syringes, infusion sets, etc., can solve the problems of poor sliding properties between the core rod and the jacket, and achieve excellent self-lubricating, high lubricating, and reasonable formula effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 100 parts by weight of polypropylene resin (melting temperature is 140°C; at 230°C, the melt flow rate of 2.16kg is 18g / 10min) and 1.2 parts by weight of polytetrafluoroethylene micropowder (particle size 6μm), mixed at high speed After mixing evenly in the machine, it is added to a twin-screw extruder, kneaded, extruded, cooled, dried, granulated, and packaged to obtain a self-lubricating polypropylene composite material.

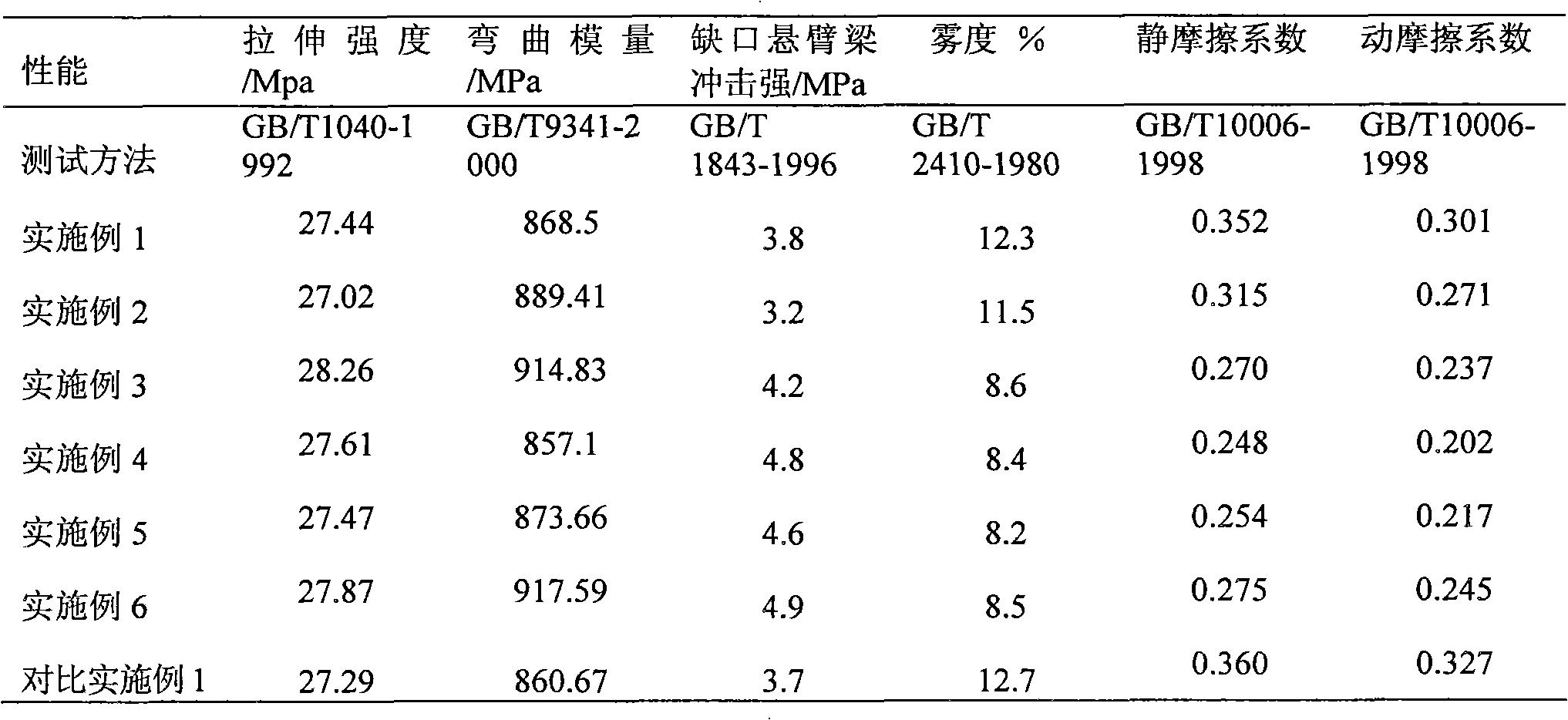

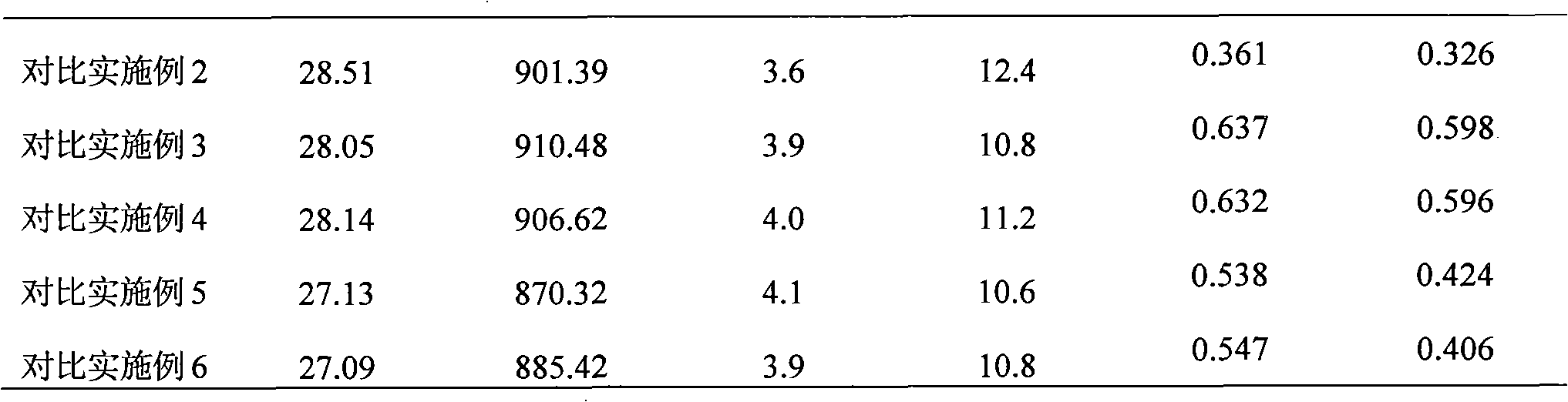

[0020] The tensile strength, flexural modulus, notched Izod impact strength, haze, static friction coefficient and dynamic friction coefficient of the obtained polypropylene composite materials were tested, and the results are shown in Table 2.

Embodiment 2

[0022] 100 parts by weight of polypropylene resin (melting temperature is 165°C; under the condition of 230°C, the melt flow rate of 2.16kg is 30g / 10min) and 1.6 parts by weight of polytetrafluoroethylene micropowder (particle size 3μm), mixed at high speed After mixing evenly in the machine, it is added to a twin-screw extruder, kneaded, extruded, cooled, dried, granulated, and packaged to obtain a self-lubricating polypropylene composite material.

[0023] The tensile strength, flexural modulus, notched Izod impact strength, haze, static friction coefficient and dynamic friction coefficient of the obtained polypropylene composite materials were tested, and the results are shown in Table 2.

Embodiment 3

[0025] 100 parts by weight of polypropylene resin (melting temperature is 150°C; at 230°C, the melt flow rate of 2.16kg is 30g / 10min) and 0.8 parts by weight of simethicone oil (viscosity 60,000mPas), in a high-speed mixer After mixing evenly in the middle, it is added into a twin-screw extruder, kneaded, extruded, cooled, dried, granulated, and packaged to obtain a self-lubricating polypropylene composite material.

[0026] The tensile strength, flexural modulus, notched Izod impact strength, haze, static friction coefficient and dynamic friction coefficient of the obtained polypropylene composite materials were tested, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com