Mechanical-electrical liquid mixing soft start stepless speed regulator

A technology of stepless speed regulation and soft start, which is applied in the direction of motor generator/starter, electric motor/converter plug, electromechanical device, etc., which can solve the problems of high price, high maintenance cost and high price of variable frequency controller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

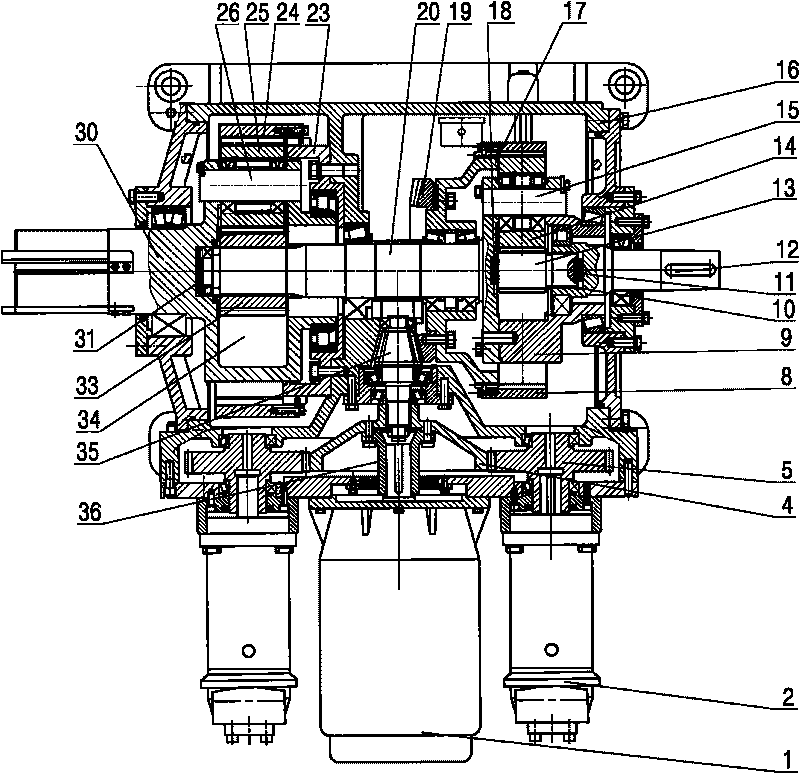

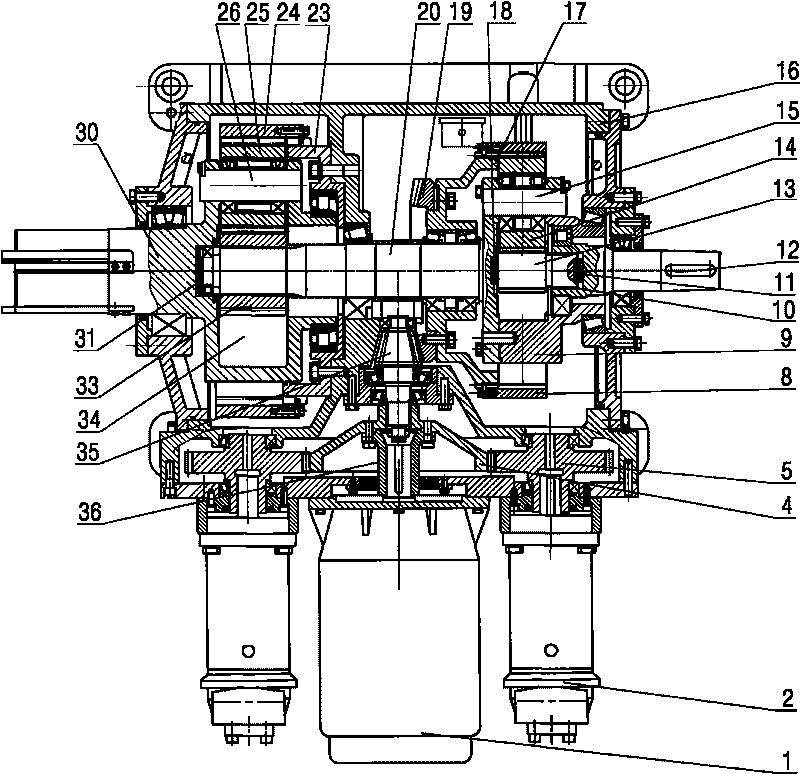

[0026] see figure 1 The present invention includes a box body 16 and a high-speed input shaft 12 fixed on the box body 16 by a roller bearing. One end of the high-speed input shaft 12 extends out of the box body 16 and is connected with the rotating shaft of the main motor, and the other end is provided with a first The inner hole 10 and its outer part are sleeved with a high-speed planet carrier 9 through roller bearings. The first inner hole 10 of the high-speed input shaft 12 is provided with involute spline inner teeth, and the involute spline inner teeth are connected with the outer teeth of the high-speed sun gear shaft 13 to form backlash floating. At the same time, one end of the high-speed sun gear shaft 13 is axially positioned through the block 11 and the high-speed input shaft 12, and the other end is axially positioned through the top block 18 and the low-speed input shaft 20 fixed in the box 16 through roller bearings. . The other end of the low-speed input sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com