Electric-control wide-angle light scanning device and array thereof

A light scanning device, wide-angle technology, applied in the direction of optics, optical components, instruments, etc., to achieve the effect of high steering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

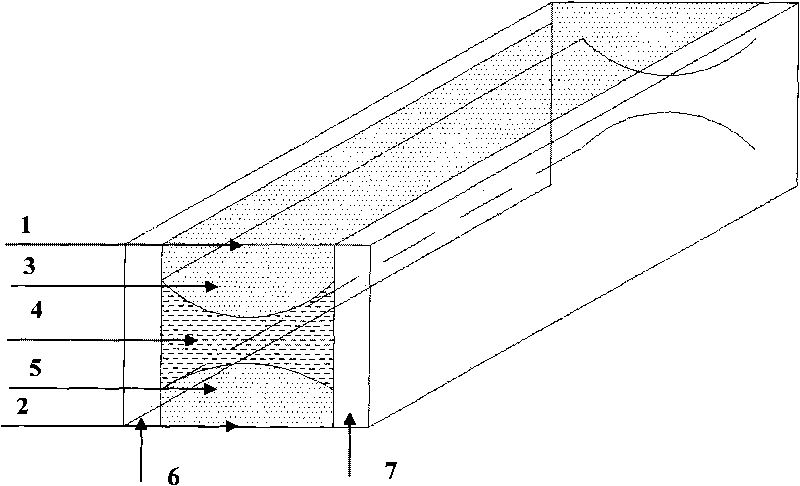

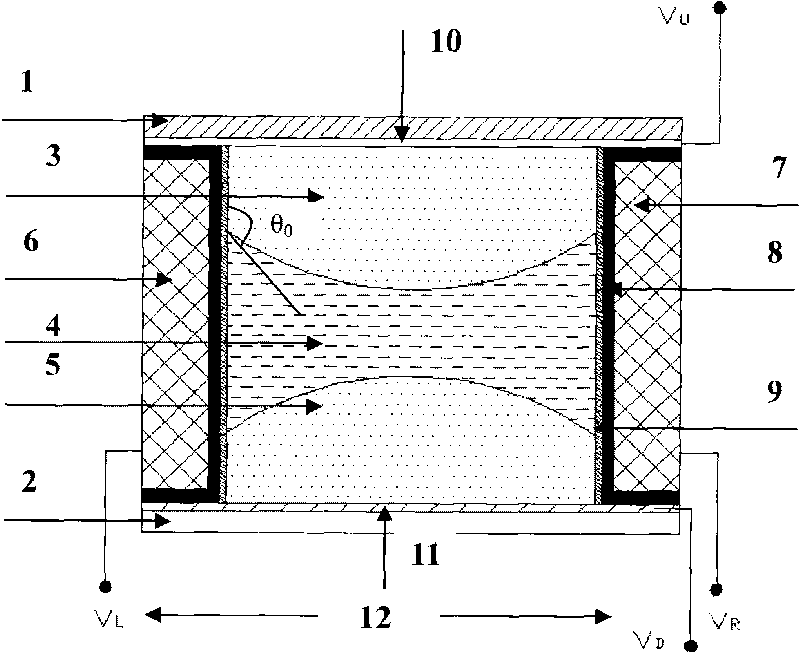

specific Embodiment 1

[0041] like figure 1 , 2 As shown, the conductive materials 6 and 7 on the left and right sides are metal materials with good electrical conductivity, and a 3-micron-thick parylene is formed as the insulating layer 8 on the surface of the metal material by vacuum coating. The hydrophobic layer 9 is realized by dipping the hydrophobic agent FOTs. Conductive Fluids 3 and 5 use a saline solution which may have freezing problems when used at low temperatures. High concentration salt solutions can be used to lower the freezing point. In order to maintain the low density and refractive index of the brine, a low atomic weight salt is used: lithium chloride. Lithium chloride at a concentration of 20% results in a freezing point below -40°C, a density ρ of 1.12kg / m3, and a refractive index of 1.38. Insulating fluid 4 uses a mixed phenylmethylsiloxane, which has a high refractive index and good electrowetting properties. Dissolve a few percent carbon tetrabromide (ρ=2.96kg / m 3 ) ...

specific Embodiment 2

[0044] like figure 1 , 2 As shown, the conductive materials 6 and 7 on the left and right sides are doped conductive material Si, and a layer of 500nm SiO is oxidized on the surface of Si. 2 as an insulating layer 8. The transparent substrate still uses a high-performance cover glass sputtered ITO film layer. The hydrophobic layer 9 is realized by dipping the hydrophobic agent FOTs. Use a saline solution. Hydrophobic layer 9 adopts polytetrafluoroethylene polymer material (English abbreviation is PTFE, trade name Teflon Teflon@AF) coating to achieve. The insulating fluid is bromododecane (density 1.0399, refractive index 1.4583), and the conductive fluids 3 and 5 are saline solutions configured to have the same density to remove the influence of gravity. The voltage controls the shape of the interface between the insulating fluid and the conductive fluid to adjust the shape and position of the liquid prism, thereby realizing the electronically controlled wide beam pola...

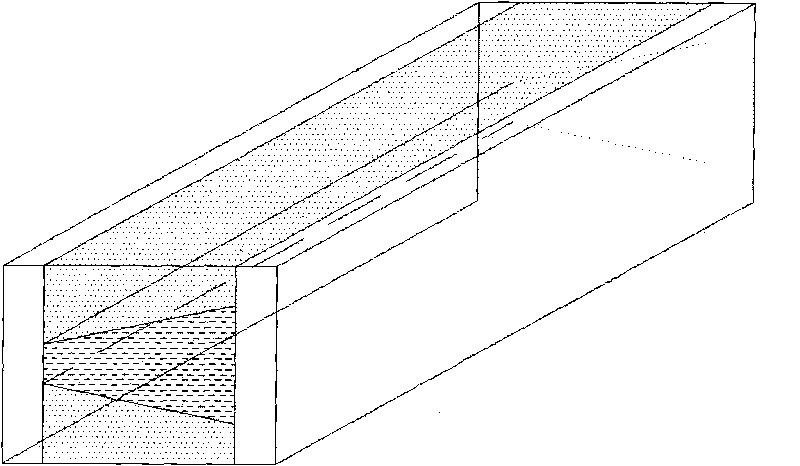

specific Embodiment 3

[0045] Other manufacturing process is the same as embodiment 1 and 2. The electronically controlled wide-angle optical scanning device of embodiment 1 or 2 is made into an electronically controlled optical scanning array device (transverse linear, vertical linear and planar) by the bonding method, or an array device is fabricated on a whole piece of base material. On the basis of Embodiment 1 or 2, the long channel-shaped liquid tank is designed as a square liquid tank, and then the front and rear walls are made of conductive materials, and an insulating layer is arranged between the front and rear walls and the left and right walls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com