Preparing process of warm beer

A technology for manufacturing warm beer, which is applied in the field of warm beer manufacturing, can solve problems such as limited nutritional value, achieve rich nutritional value and reduce the effect of getting angry easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

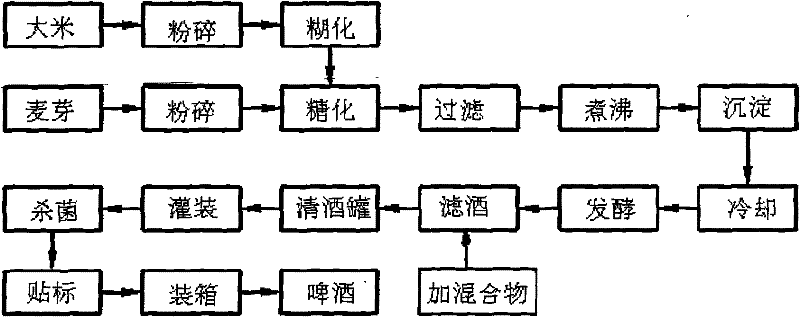

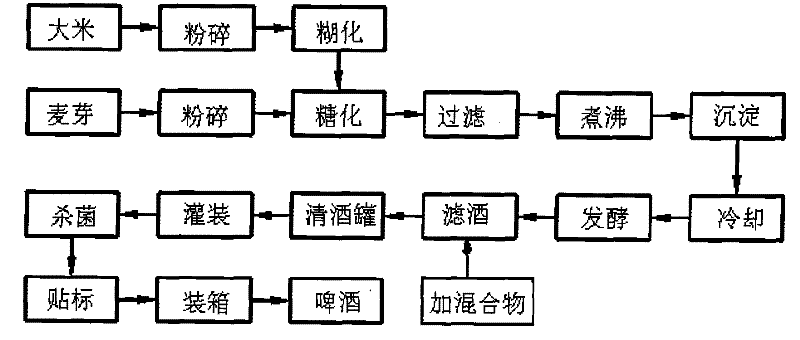

Method used

Image

Examples

Embodiment 1

[0018] (1) After the black rice is pulverized by a rice grinder, put it into the gelatinization pot and add an appropriate amount of mountain spring water at 50°C. After 20 minutes, the temperature is raised to 70°C and kept for 10 minutes. After 20 minutes, the temperature is raised to 90°C and kept for 15 minutes. Raise the temperature to 100°C in 10 minutes and keep it warm for 30 minutes to obtain gelatinized mash;

[0019] (2) After the malt is crushed by a malt grinder, it is put into the mash pot and an appropriate amount of mountain spring water at 45°C is added. After the protein is rested for 50 minutes, the black rice gelatinized mash is put into the mash pot and malt mash, and the temperature is raised for 10 minutes. to 68-70°C and hold for 60 minutes.

[0020] (3) After the saccharification is complete by iodine test, the saccharified mash is obtained, the mixed mash is heated to 76-78°C to kill enzymes, and then filtered through the sedimentation tank to obtain ...

Embodiment 2

[0029] According to the ratio by weight, mountain spring water 4.5, malt 0.5, black rice 0.4, hops 0.002, according to the reaction step (1-3) in the embodiment 1, make 10 0 P wort, then add yeast for fermentation, the amount of yeast added is 10.0×10 6 pcs / ml, fermented for 8 days, after fermented and matured, cooled to 0--1°C, zero storage for 4 days, after the yeast on the bottom surface was discharged, muddy wine was obtained, which was sent to filtration;

[0030] Dilute the concentrated solution of hawthorn, red dates, wolfberry and ginger juice with deoxygenated water, deoxygenate and adjust the pH value to 4.0-4.4 with edible lactic acid to obtain a mixed solution, and then use a metering pump to add it to the murky wine through a pipeline to beat Put it into a diatomaceous earth filter to filter to obtain sake, the turbidity of the sake is controlled at 0.4-0.5EBC, the sake is sent into the sake tank, and after filling, it is pasteurized and labeled to obtain the fini...

Embodiment 3

[0033] According to the ratio by weight, mountain spring water 4.0, malt 0.6, black rice 0.5, hops 0.003, according to the reaction step (1-3) in the embodiment 1, make 11 0 P wort, then add yeast for fermentation, the amount of yeast added is 11.0×10 6 pcs / ml, ferment for 9 days, after the fermentation is mature, cool down to 0--1°C, zero storage for 5 days, after the yeast on the bottom surface is discharged, the muddy wine is obtained, and sent to filtration;

[0034] Dilute the concentrated solution of hawthorn, red dates, wolfberry and ginger juice with deoxygenated water, deoxygenate and adjust the pH value to 4.0-4.4 with edible lactic acid to obtain a mixed solution, and then use a metering pump to add it to the murky wine through a pipeline to beat Put it into a diatomaceous earth filter to filter to obtain sake, the turbidity of the sake is controlled at 0.4-0.5EBC, the sake is sent into the sake tank, and after filling, it is pasteurized and labeled to obtain the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com