Direct combustion dispersed heat supplying method for biomass pyrolysis furnace

A biomass pyrolysis and pyrolysis furnace technology, which can be applied in combustion methods, biofuels, direct heating and dry distillation, etc. The effect of thermal safety, improving comprehensive economic benefits and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

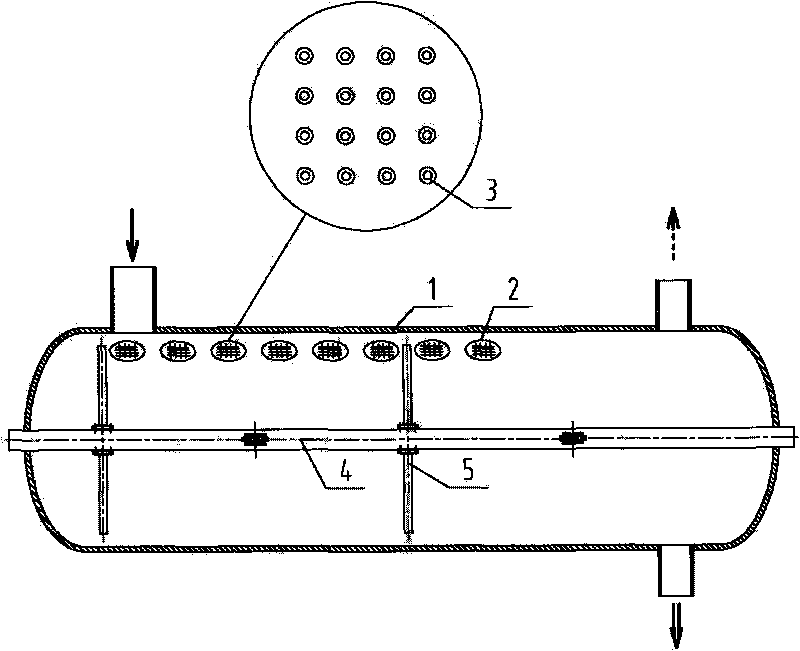

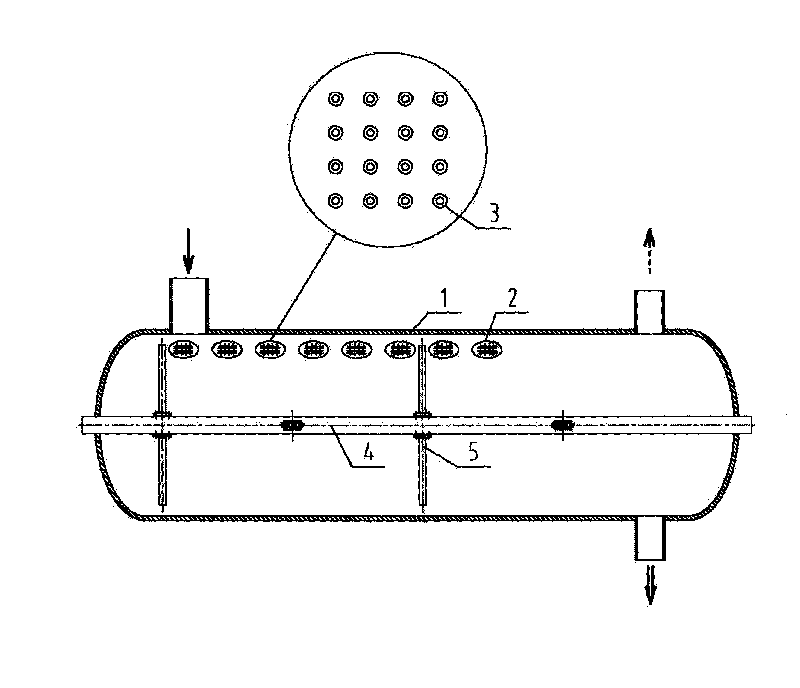

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0035] A direct combustion decentralized heat supply method for a biomass pyrolysis furnace. The heat supply combustion device of the pyrolysis furnace is composed of a plurality of burner groups, and all the burner groups are arranged on the upper part of the pyrolysis furnace. The upper part is distributed along the axial direction, and each burner group is composed of multiple small burner nozzles. The maximum temperature of the combustion area in the pyrolysis furnace is controlled below 1600°C.

[0036] In the direct combustion decentralized heat supply method of the biomass pyrolysis furnace, the fuel and oxidant for the combustion and heat supply of the pyrolysis furnace are separated before entering the pyrolysis furnace, and in the pyrolysis furnace are non-premixed combustion.

[0037] The direct combustion decentral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com