Absorption distillation method for using adsorption resin to treat waste water containing dimethyl formamide

A technology of dimethylformamide and adsorption resin, which is applied in the field of dimethylformamide wastewater treatment, can solve the problems of rectification and separation energy consumption reduction, energy consumption reduction, large energy consumption, etc., and achieve a reduction in the amount of desorbent , The latent heat of vaporization is small, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

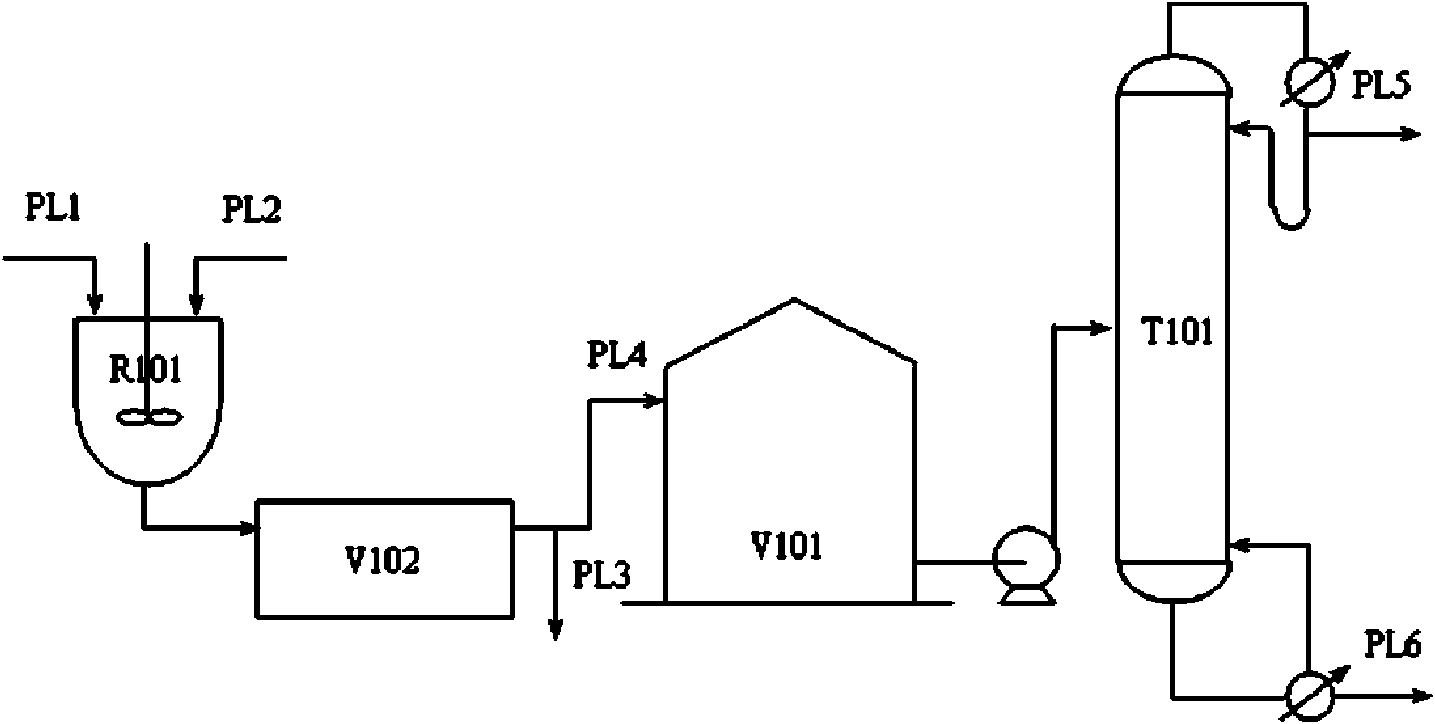

[0015] The present invention has two kinds of specific implementation methods, which are explained below in conjunction with the accompanying drawings:

[0016] Specific implementation method one

[0017] (1) Add the wastewater containing dimethylformamide DMF into the intermittent stirring tank R101, and conduct mass transfer with the macroporous adsorption resin in the stirring tank at normal temperature and pressure, so that the dimethylformamide DMF in the wastewater is adsorbed on the resin superior;

[0018] (2) Separating the adsorbed resin and waste water through the settling tank V102 for solid-liquid separation. After the solid-liquid separation, the resin adsorbed with dimethylformamide DMF is recovered and re-enters the batch stirring tank for desorption;

[0019] (3) Add a desorbent from the desorbent input pipeline PL2 to the intermittent stirring tank for desorption, obtain a mixed solution of dimethylformamide DMF and a desorbent, and store the mixed solution ...

Embodiment 1

[0031] Add various types of resins (including C series, D series, H series, NKA series, DA series, DK series, XAD series, AB-8 type), bentonite, chitosan, coal-based activated carbon, fruit shell activated carbon, and fiber activated carbon are adsorbed at 30°C and 1atm. After 2 hours of adsorption, the DMF concentration of H series, NKA series, D series, and AB-8 macroporous adsorption resins can be reduced to less than 0.1%, which has a good adsorption effect; while other types of resins, bentonite , chitosan, coal activated carbon, shell activated carbon and fiber activated carbon have no obvious adsorption effect.

Embodiment 2

[0033] The dimethylformamide wastewater with a mass concentration of 20% is adsorbed with the macroporous adsorption resin NKA-II in a batch stirring tank under the conditions of 1atm and 30°C, and the mass concentration of DMF in the waste liquid after adsorption for 3.5 hours is <0.05% , the resin adsorbed with DMF was drained and desorbed for 2 hours with ethanol twice the volume of waste water under the same conditions, and the mass concentration of DMF in the eluent was 9.58%. The eluent enters the rectifying tower from the 8th tray on the top of the tower, the rectifying tower pressure is 1atm, the total plate number of the rectifying tower is 45, the operating reflux ratio is 1, and the ethanol mass concentration of the tower top production liquid is 94.9%, recovery and recycling, the mass concentration of DMF at the bottom of the tower is 99.8%, and the total recovery rate of DMF can reach 96.2%.

[0034] Under the same conditions, the energy consumption of the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com