Natural high class fatty alcohol emulsion and preparation method thereof

A high-grade fatty alcohol and natural technology, applied in the direction of defoaming agent, foam dispersion/prevention, etc., can solve the problems of unstable fatty alcohol emulsion, lower use cost, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

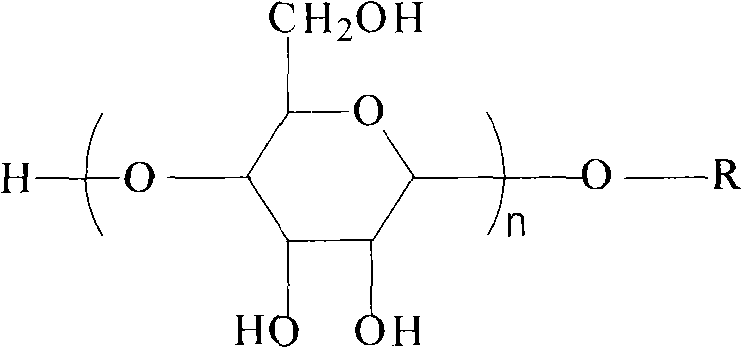

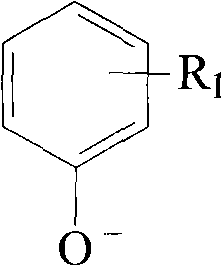

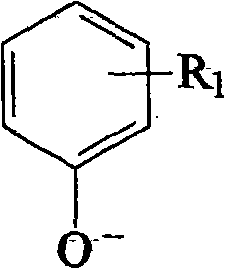

Method used

Image

Examples

Embodiment 1

[0032] take C 14 -C16 100 parts of alcohol, 50 parts of solid paraffin, the above raw materials were mixed and melted, stirred and heated to 70°C to obtain the mixture (1). Take 1 part of polyether (M is dodecyl, x=60, y=0) and 0.5 part of APG and add it to 200 parts of water at 80°C to obtain the mixture (2). Slowly add the mixture (1) to the mixture (2), then use a high-shear device, and dilute it with water to an emulsion with a concentration of 30%, and finally add a thickener polymethacrylate to adjust its viscosity to 286mPa·s. Can. Example 2:

Embodiment 2

[0033] take C 18 100 parts of alcohol, 40 parts of solid paraffin, the above raw materials were mixed and melted, stirred and heated to 90°C to obtain the mixture (1). Take 2 parts of polyether (M is n-octyl, x=40, y=0) and 2.3 parts of APG and add them to 250 parts of water at 70°C to obtain the mixture (2). Slowly add the mixture (1) to the mixture (2), then use a high-shear device, and dilute it with water to an emulsion with a concentration of 25%, and finally add a thickener polymethacrylate to adjust its viscosity to 275mPa·s. Can.

Embodiment 3

[0035] take C 24 100 parts of alcohol, 70 parts of solid paraffin, the above raw materials were mixed and melted, stirred and heated to 90°C to obtain the mixture (1). Add 2.5 parts of polyether (M is n-hexyl, x=90, y=30) and 1 part of APG to 300 parts of water at 90°C to obtain mixture (2). Slowly add the mixture (1) to the mixture (2), then use a high-shear device, and dilute it with water to an emulsion with a concentration of 30%, and finally add a thickener polymethacrylate to adjust its viscosity to 302mPa·s. Can.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com