Preparation method for novel bean curd and frozen bean curd

A technology of tofu and weight percentage is applied in the production field of tofu and frozen tofu, and can solve the problems of complex tofu process and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

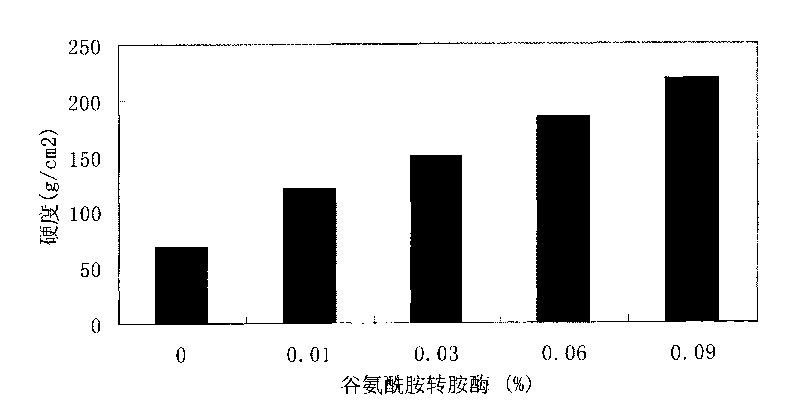

[0017] The weight percent of each raw material of the tofu is: 15% of soybean protein isolate, 10% of soybean oil, 3% of corn starch, and a transglutaminase with an enzyme activity unit of 100 U / g is added. In the four different samples, the amount of transglutaminase added was different, and the amount was 0.01%, 0.03%, 0.06% and 0.09%, respectively. At the same time, in this experiment, the sample without adding transglutaminase was used as the control substance.

[0018] The preparation steps are: fully mix soybean protein and ice water, chop and mix at high speed for 30 minutes with a chopping machine, then add transglutaminase, continue chopping and mixing at high speed for 5 minutes, add cornstarch and soybean oil in turn, continue chopping at high speed Mix for 5 minutes, chop and mix all the materials evenly; put the chopped and mixed materials into the mold, keep warm at 50°C for 1 hour; cut into pieces, put them in a cooking pot, and cook at 85-95°C for 25 -35 minut...

Embodiment 2

[0021] The weight percent of each raw material of the tofu is: 15% of soybean protein isolate, 10% of soybean oil, 3% of corn starch, and 0.06% of transglutaminase with an enzyme activity unit of 80-120U / g.

[0022] The preparation steps are: fully mix soybean protein and ice water, chop and mix at high speed for 30 minutes with a chopping machine, then add transglutaminase, continue chopping and mixing at high speed for 5 minutes, add cornstarch and soybean oil in turn, continue chopping at high speed Mix for 5 minutes, chop and mix all the materials evenly; put the chopped and mixed materials into the mold, keep warm at 50°C for 1 hour; cut into pieces, put them in a cooking pot, and cook at 85-95°C for 25 -35 minutes, after cooking, it will be tofu with unique taste.

Embodiment 3

[0024] The raw materials are the same as in Example 2, and 0.06% magnesium chloride by weight is added in addition.

[0025] The preparation steps are: fully mix soybean protein and ice water, chop and mix at high speed for 30 minutes with a chopping machine, then add transglutaminase, continue chopping and mixing at high speed for 5 minutes, add cornstarch and soybean oil in turn, continue chopping at high speed Mix for 5 minutes, finally add 0.06% magnesium chloride, continue chopping and mixing at high speed for 5 minutes, then fully chop and mix all the materials evenly; put the chopped and mixed materials into the mold, keep warm at 50°C for 1 hour; cut into pieces, put In a steaming pot, cook at a temperature of 85-95° C. for 25-35 minutes, and the tofu with unique taste will be obtained after being cooked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com