Use of statistical analysis in power plant performance monitoring

A technology of correlation analysis and performance, applied in electrical test/monitoring, test/monitoring control system, calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

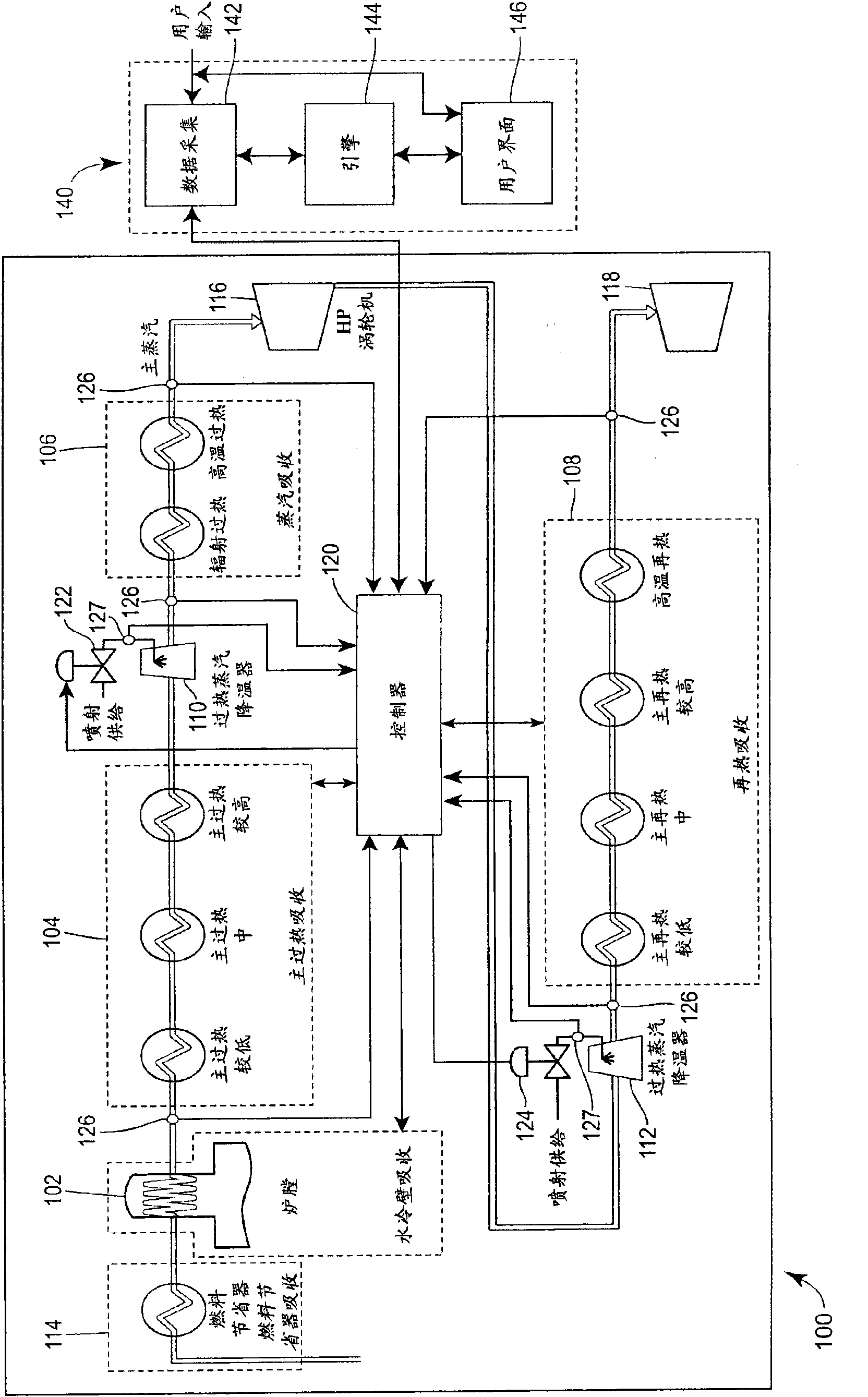

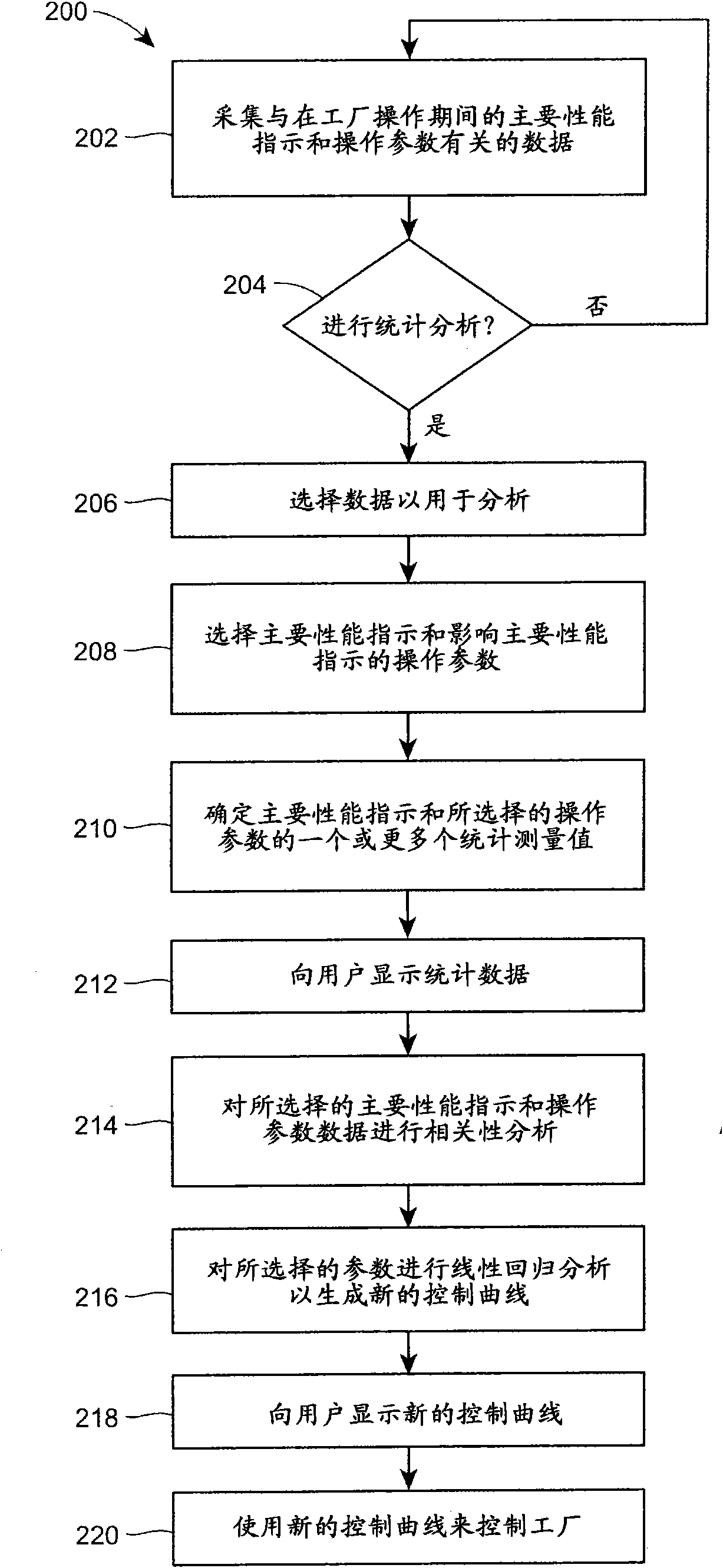

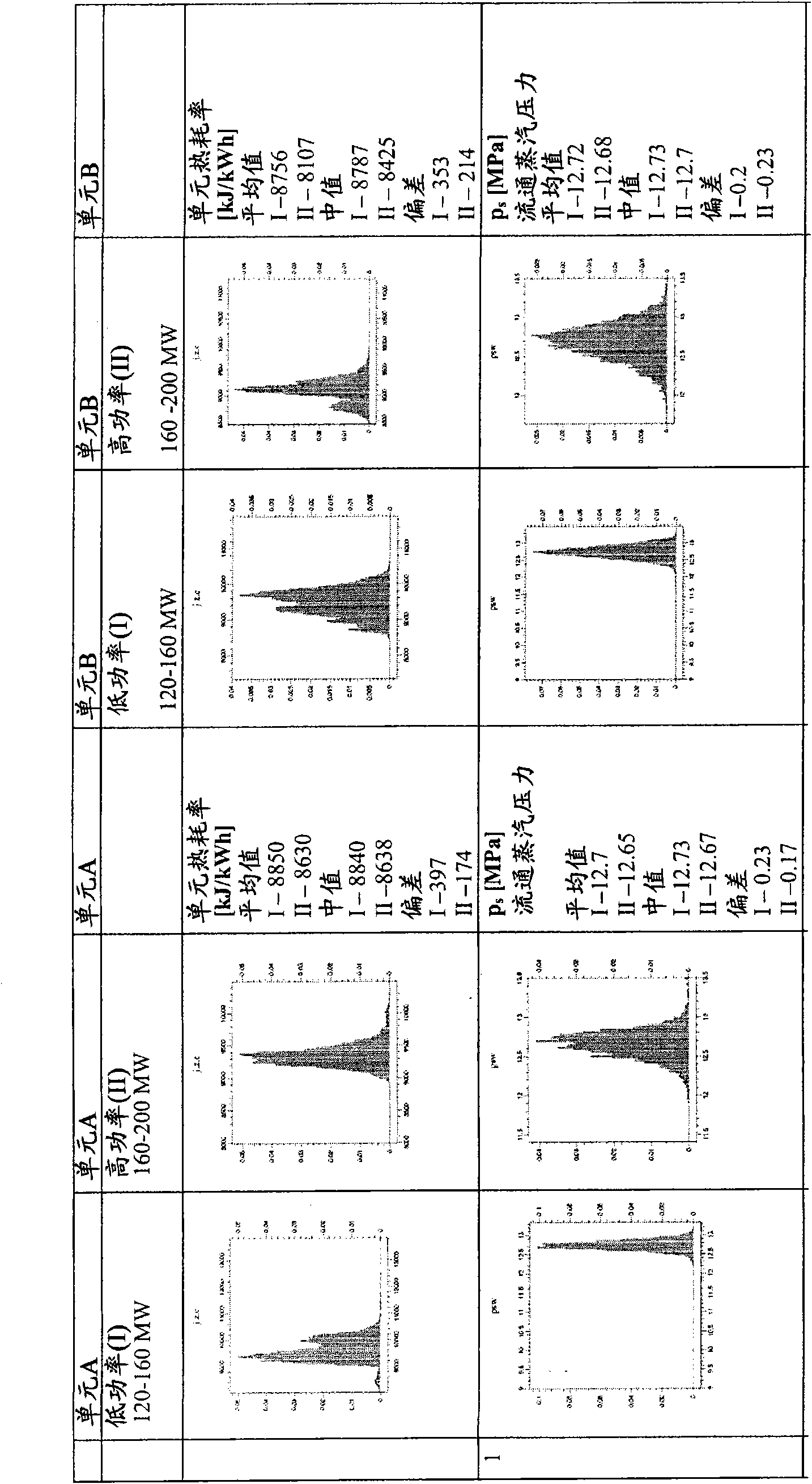

[0022] Computer-based digital automatic control systems, which now exist in many power plants, allow near continuous monitoring and control of plant performance by monitoring all performance parameters (or losses) on-line and by allowing direct operator supervision and supervision. Improvements in the quality of measurement equipment and tools have also greatly eased the tasks of periodic heat rate testing and warranty. However, the high-quality nature of automated distributed control systems (DCS) linked to common optimization systems (which act in place of the operator during normal unit operations) has reduced the possibility of obtaining simple exponential improvements in efficiency. To this end, the main task of performance monitoring can now be changed to the actual detection of possible losses associated with operating a particular generating unit in a market-based generation allocation.

[0023] To this end, a new method of implementing power plant performance monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com