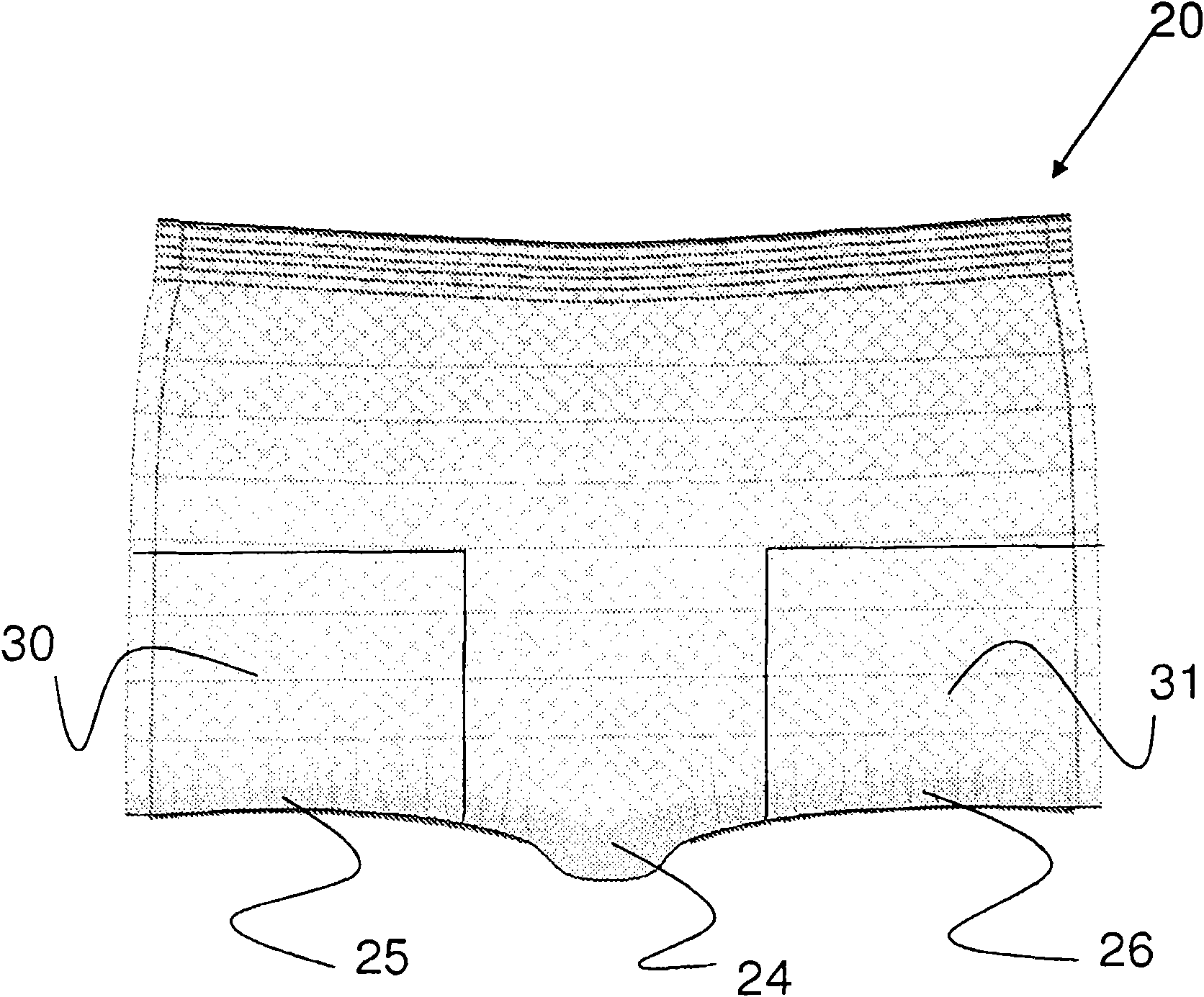

A warp-knitted pant having U-shaped crotch

A technology of underpants and warp knitting, applied in the direction of warp knitting, underwear, baby underwear, etc., can solve the problems of loose structure, expensive dissolvable yarn, etc., and achieve the effect of high stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0057] In a particular test pant (A) according to the invention, which had an approximately 1 cm wide region in the crotch region near the crotch seam 35, comprising a tricot satin structure and a Laying yarn in position that goes over 3 needles and spring-loaded latch needle in every 2nd stitch position that knits without using yarn in every 4th stitch, lengthwise to the crotch Measure the stretchability on the A 5 cm long test area (measured from the crotch seam and upwards on the front panel of the unstretched panty in the relaxed state) is marked on the panty, which is fully stretched by hand until the structure is locked. The stretch length is 26.5 cm, which equates to a stretchability of 430%.

[0058] As a comparison, a pair of conventional raschel panties (B), not made in accordance with the present invention, having a tricot satin structure in the crotch area and approximately 1 There is a lap yarn in the centimeter wide area. The stretched length at this point is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com