A flexible strain sensor with regular crack structure and its manufacturing method

A technology of strain sensor and crack, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of low cost and large-scale production of flexible strain sensor, poor consistency of flexible strain sensor, long recovery time, etc. Achieve the effects of flexible adjustment methods, improved mechanical properties and structural stability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

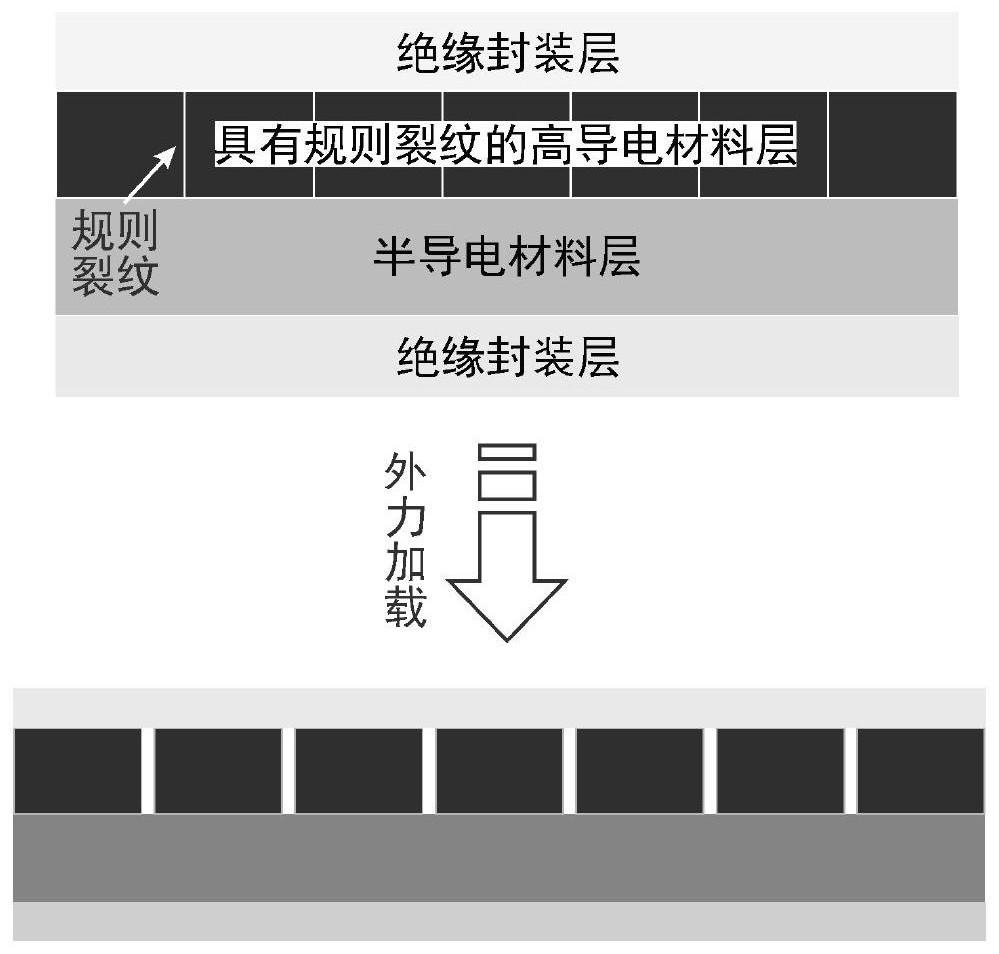

[0068] Such as figure 1 As shown, the flexible strain sensor with a regular crack structure in this embodiment has a layered structure, the top layer and the bottom layer are the insulating packaging layers of the flexible strain sensor, and the middle is the mechanically sensitive layer of the flexible strain sensor. The mechanically sensitive layer is composed of a high conductive material layer with regular cracks on the upper layer and a semiconductive material layer on the lower layer.

[0069] Specifically, the insulating encapsulation layer uses polydimethylsiloxane, a flexible polymer material.

[0070] Specifically, the regular cracks on the highly conductive material layer with regular cracks are obtained by cutting after processing into a film. Regular cracks are periodic linear cracks, the width of a single crack is 1 micron, and the distance between adjacent cracks in the same direction is 150 microns. The sheet resistance value of the highly conductive material...

Embodiment 2

[0091] Such as Figure 9 As shown, the flexible strain sensor with a regular crack structure in this embodiment has a layered structure, the top layer and the bottom layer are the insulating packaging layers of the flexible strain sensor, and the middle is the mechanically sensitive layer of the flexible strain sensor. The mechanically sensitive layer is provided with a semi-conductive material layer on both the upper surface and the lower surface of the highly conductive material layer with regular cracks.

[0092] Specifically, the insulating encapsulation layer uses polydimethylsiloxane, a flexible polymer material.

[0093] Specifically, the regular cracks on the highly conductive material layer with regular cracks are obtained by cutting after processing into a film. Regular cracks are periodic linear cracks, the width of a single crack is 1 micron, and the distance between adjacent cracks in the same direction is 150 microns. The sheet resistance value of the highly co...

Embodiment 3

[0100] Such as Figure 11 As shown, the flexible strain sensor with a regular crack structure in this embodiment has a layered structure, the top layer and the bottom layer are the insulating packaging layers of the flexible strain sensor, and the middle is the mechanically sensitive layer of the flexible strain sensor. The mechanically sensitive layer is provided with a layer of highly conductive material layer with regular cracks on both the upper surface and the lower surface of the semiconductive material layer.

[0101] Specifically, the insulating encapsulation layer uses polydimethylsiloxane, a flexible polymer material.

[0102] Specifically, the regular cracks on the highly conductive material layer with regular cracks are obtained by cutting after processing into a film. Regular cracks are periodic linear cracks, the width of a single crack is 1 micron, and the distance between adjacent cracks in the same direction is 150 microns. The sheet resistance value of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com