Method for dismounting tank top system of thin oil sealing-type dry-type gas tank

A sealed gas cabinet technology, applied in the direction of adjustable capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of heavy weight of the cabinet top system, difficulty in dismantling the gas cabinet, and large construction height , to achieve the effect of fast construction speed, low construction cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

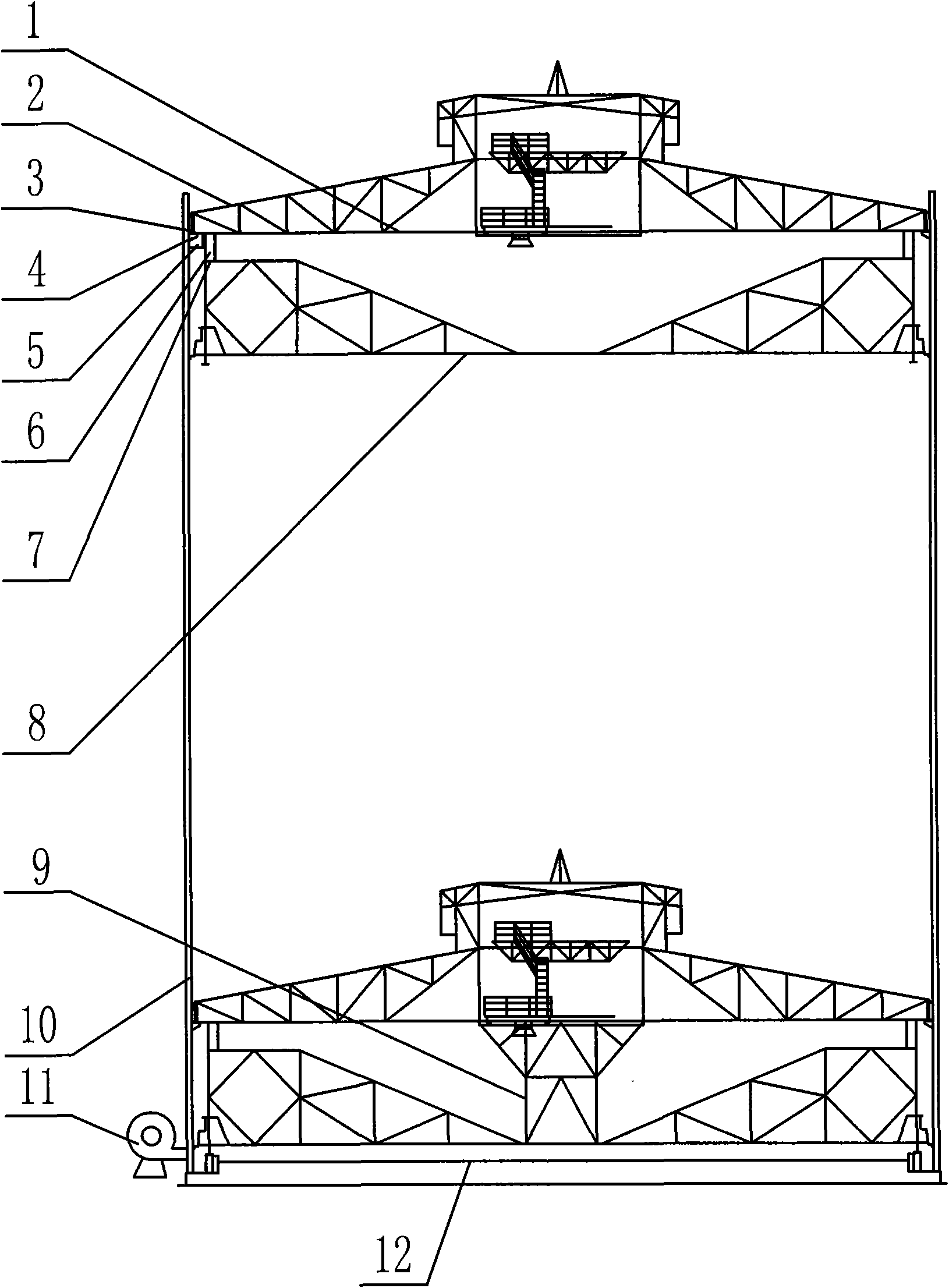

[0019] A method for dismantling the roof system of a thin oil-sealed dry-type gas tank, the specific steps of which are as follows:

[0020] 1) Make work holes on all the cabinet top plates 2 close to the connection between the cabinet top truss 1 and the column 10. The size of the work holes should meet the principle that people and equipment can pass through according to the situation, and protective railings should be set around the holes . Install the operating platform 5 at the proper position of the lower chord beam of the cabinet top truss 1. After the operating platform 5 is installed, it should be checked by the safety personnel before it can be operated by people.

[0021] 2) Install the cabinet top truss support 4 on the uppermost column 10 of the cabinet body. The cabinet top truss support 4 should be firmly welded to the column 10 and tightly connected to the cabinet top truss 1 to ensure that all the cabinet top truss supports 4 are evenly distributed Force. Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com