Torsion vibration damper

A technology of a torsional vibration damper and a vibration damping medium is applied in the field of torsional vibration dampers, which can solve the problems of weakening and unusable torsional vibration dampers, and achieve the effects of good vibration damping characteristics and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

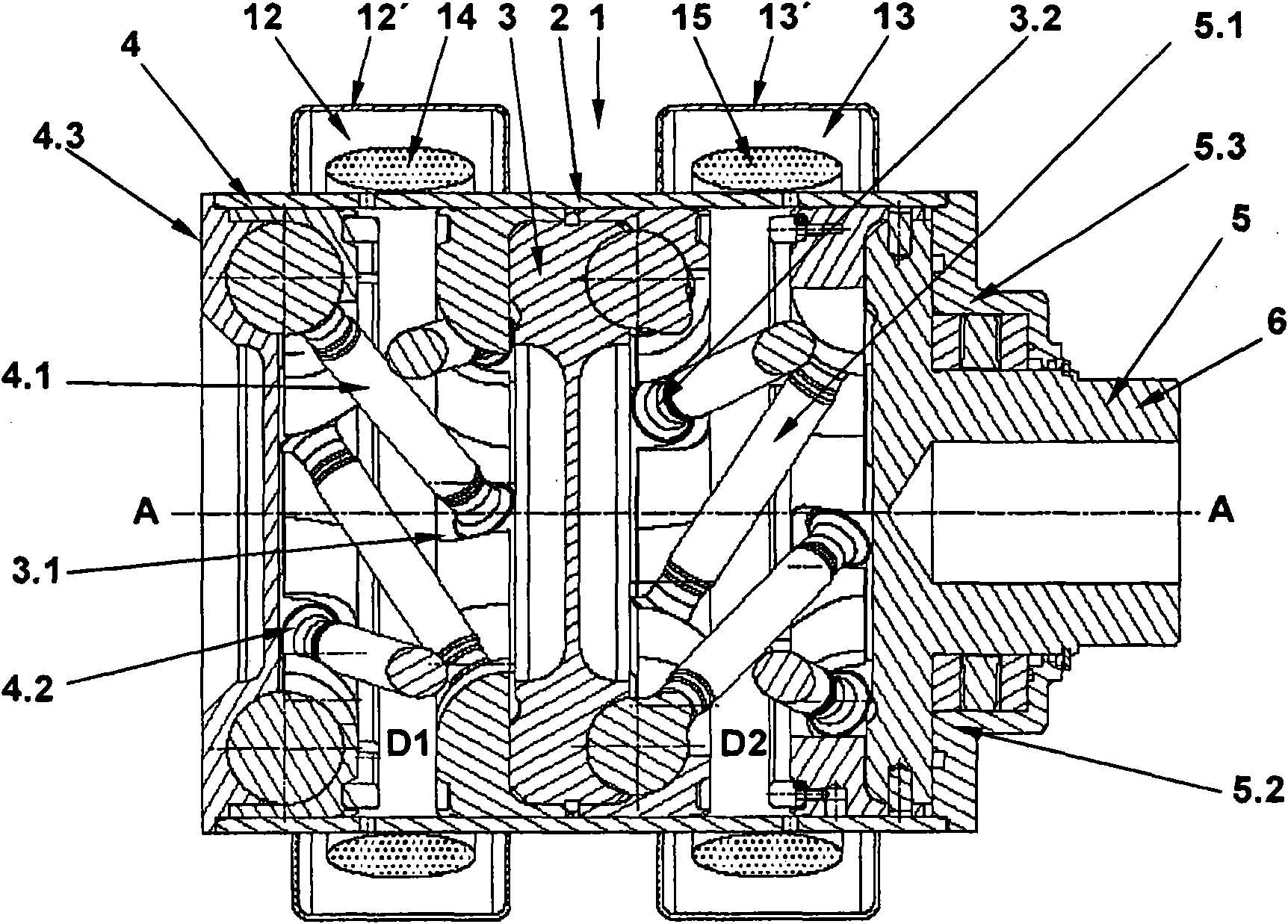

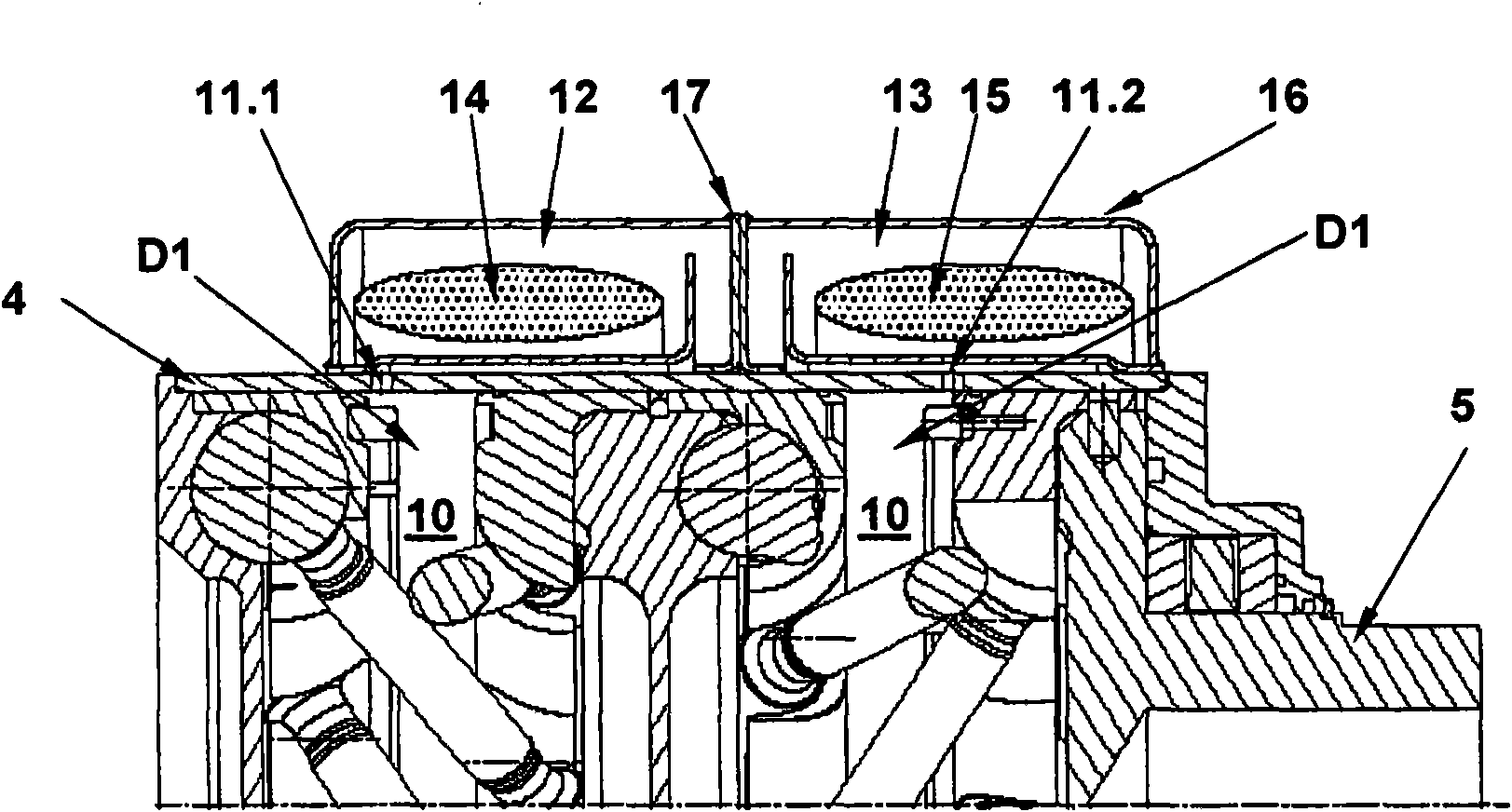

[0027] exist figure 1 and figure 2 A torsional vibration damper 1 is described, which has an axially displaceable coupling part 3 and a rotational axis 6 arranged in a housing 2 . The housing 2 forms the first element 4 and has a first housing cover 4.3. The axis of rotation 6 forms the second element 5 and passes through the second housing cover 5.3. The housing 2 (first element 4 ) and the rotation shaft 6 (second element 5 ) are rotatable relative to each other. The housing 2 (first element 4 ) is thus connected to the coupling part 3 via a rotatably mounted rigid first coupling element 4 . Element 5.1 is connected to coupling part 3. The first coupling element 4.1 is designed in the form of a ball stud and is supported with its spherical end on the one hand in a first receptacle 4.2 of the first element 4 (on the housing 2 ) so as to be rotatably movable and on the other hand It is supported for rotational movement in the receptacle 3 . 1 of the coupling part 3 . Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com