Method and device for producing an at least essentially wood-free coated paper web

A coating method, groundwood technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of time loss, impossibility of full utilization, etc., and achieve the effect of reducing web stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

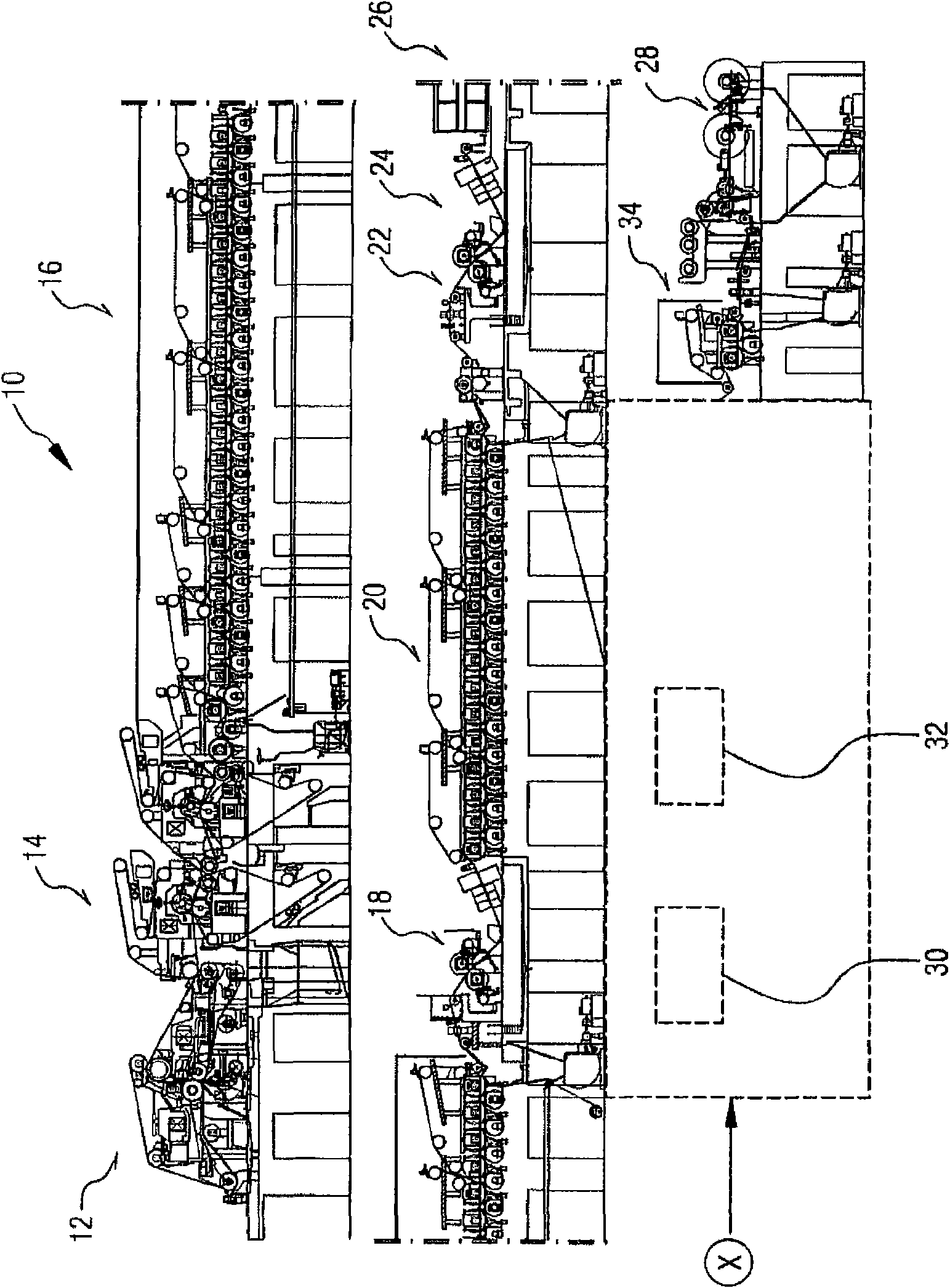

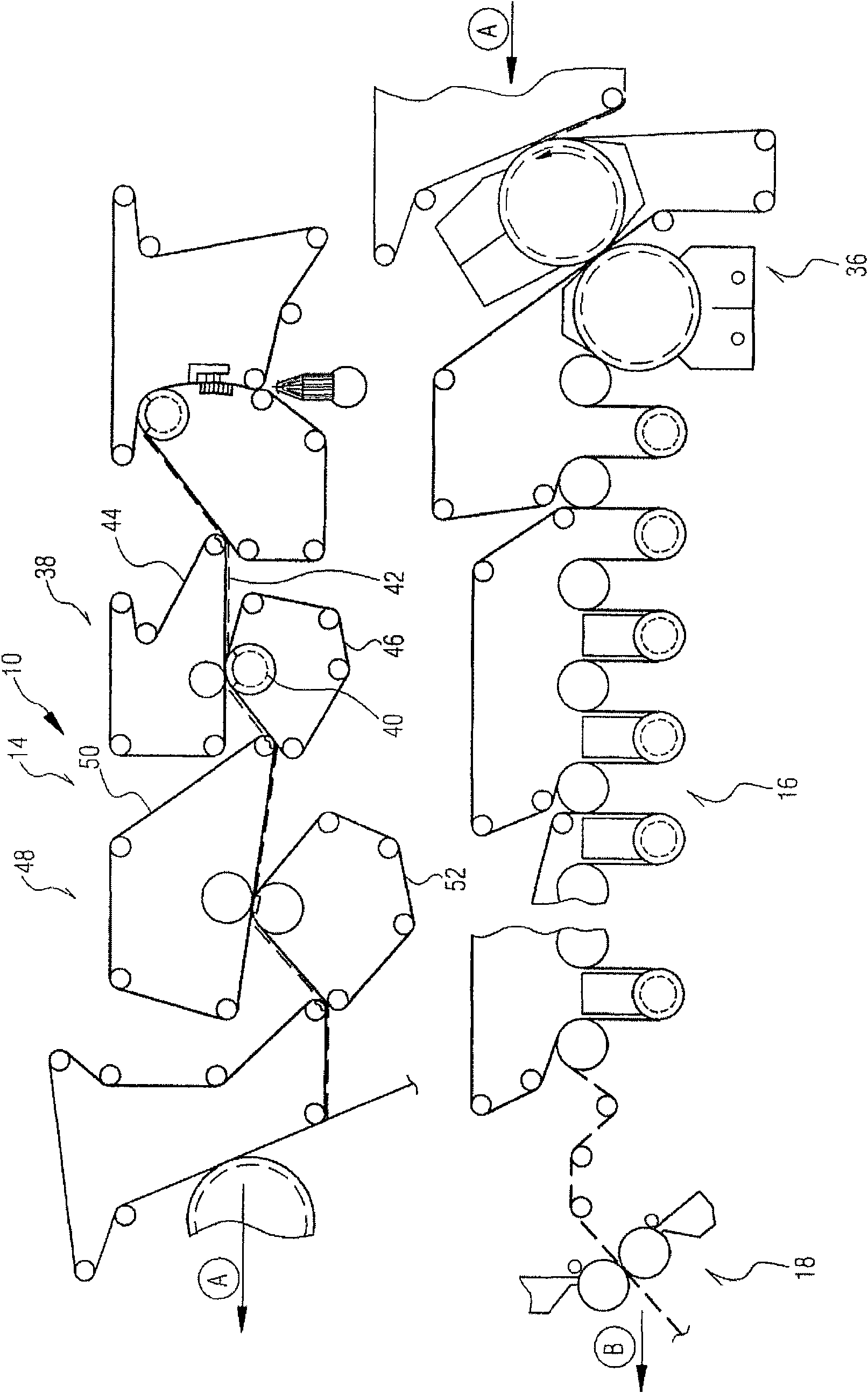

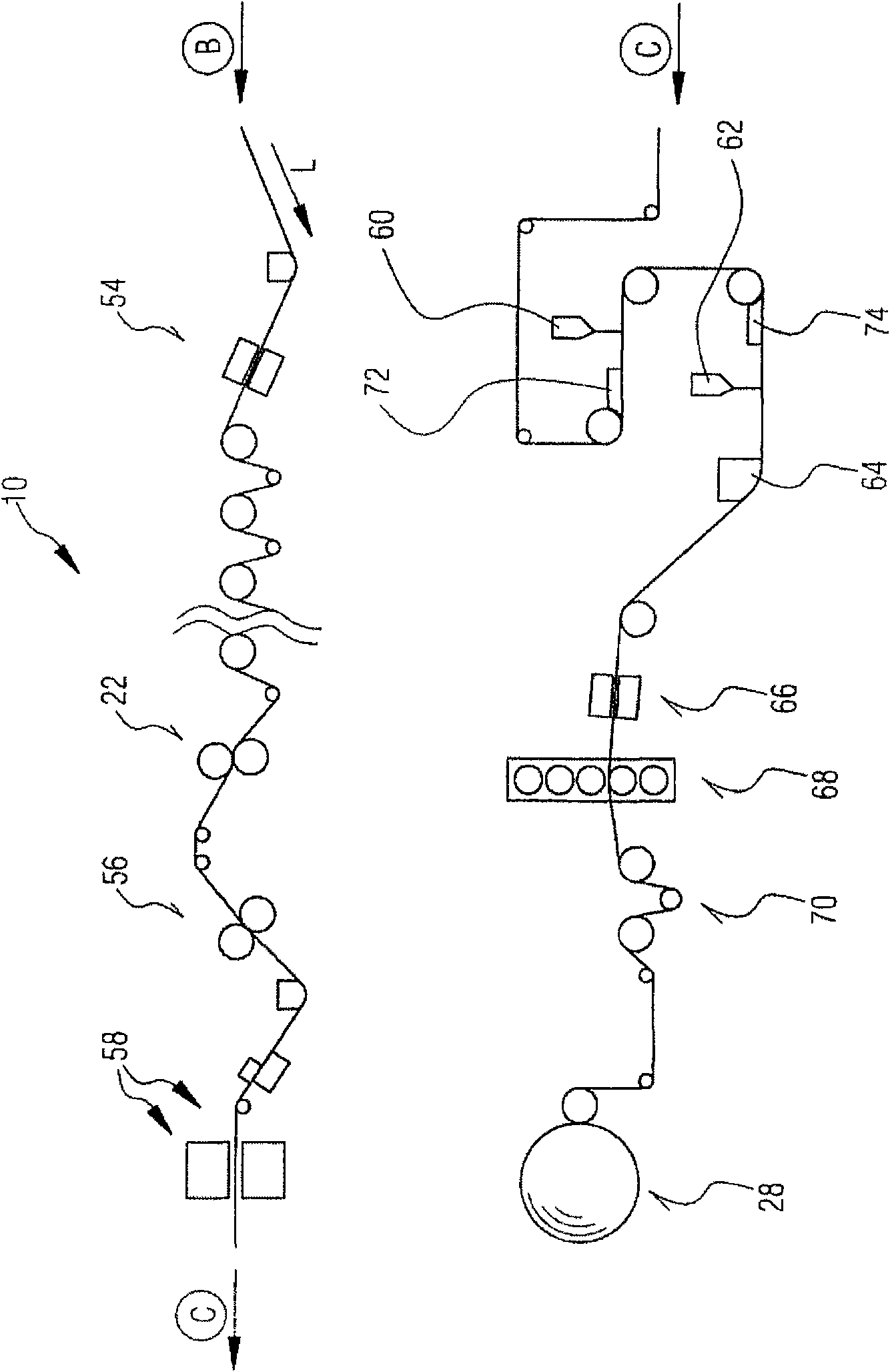

[0051]figure 1 An exemplary embodiment of an apparatus 10 for producing an at least substantially groundwood-free coated paper web is shown in schematic diagram form, with a wire section 12, a press section 14, a predryer section 18 , a device 18 for gluing, a post-drying section 20 , a calender or pre-calender 22 , a coloring device 24 , a drying device 26 and a roller 28 .

[0052] If according to figure 1 It can be seen that the gluing device 18 and the coloring device 24 are respectively, for example, film coating devices.

[0053] After the drying device 26 in the X zone and before the roller 28, two non-contact coating devices 30, 32 for two-sided coating are preferably arranged as the last coating device. Here, these last coating devices can in particular each be implemented as curtain coating devices.

[0054] For the whole online operation scheme, the paper web area with the best quality is the mass per unit area of 60g / m 2 to about 200g / m 2 Between especially a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com