Roll stand

A technology of rolling mill stand and rolling direction, applied in the direction of guide/positioning/alignment device, etc., can solve problems such as damage and damage of the guide surface, and achieve the effect of reducing the degree of damage, avoiding downtime, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

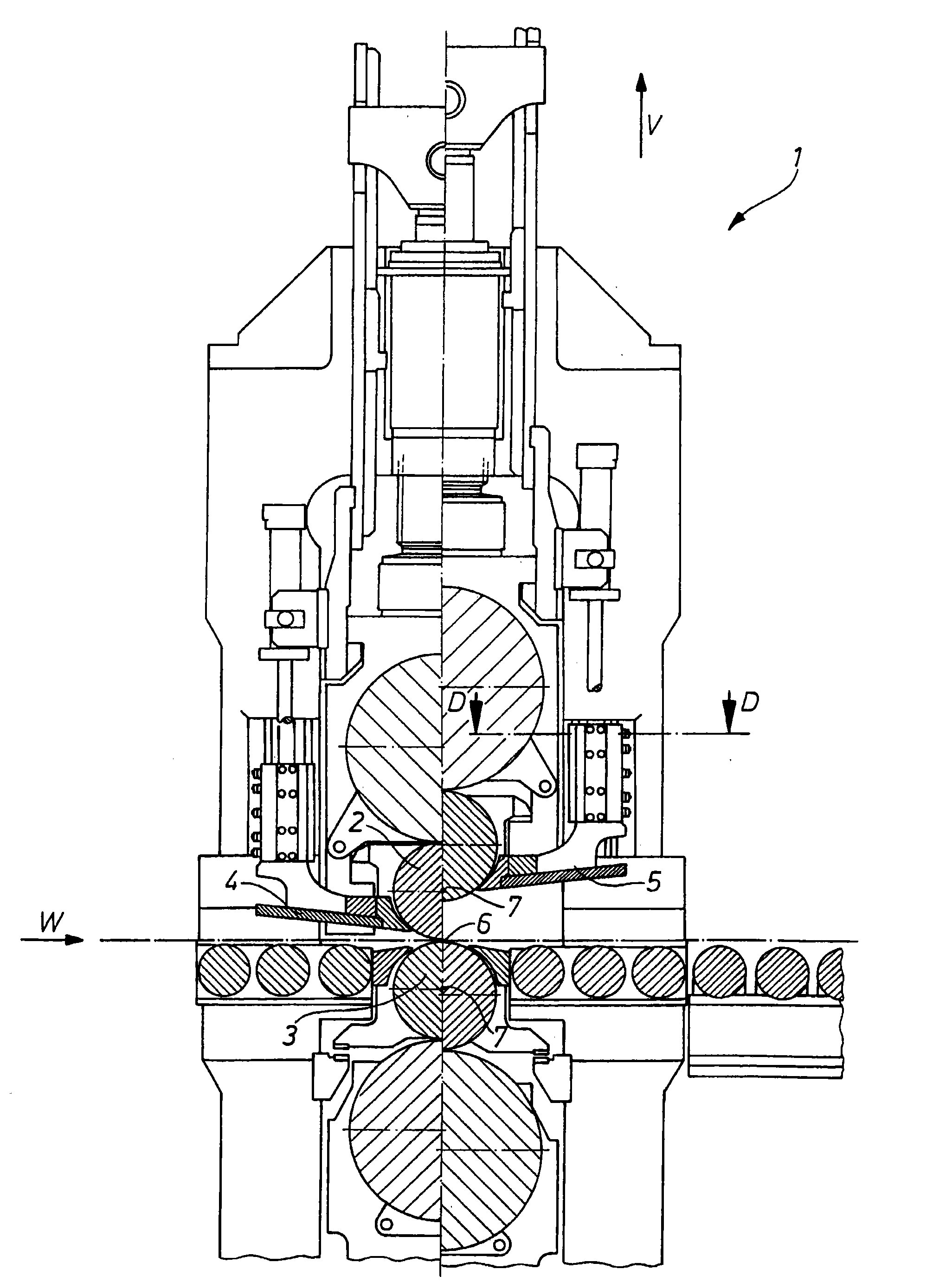

[0020] exist figure 1 shows a rolling stand 1 of a rolling installation, which is constructed in a generally known manner. On both sides of the center plane, the (working) rolls 2 , 3 of the rolling stand are shown in different vertical positions, that is to say with different roll gaps 6 between the rolls 2 , 3 . The axes 7 of the rollers 2 , 3 are here perpendicular to the plane of the drawing. The input guide 4 and the output guide 5 are located in the rolling direction W in front of and behind the rolls 2 , 3 in a known manner. The two guides 4 , 5 are adjustable in the vertical direction V.

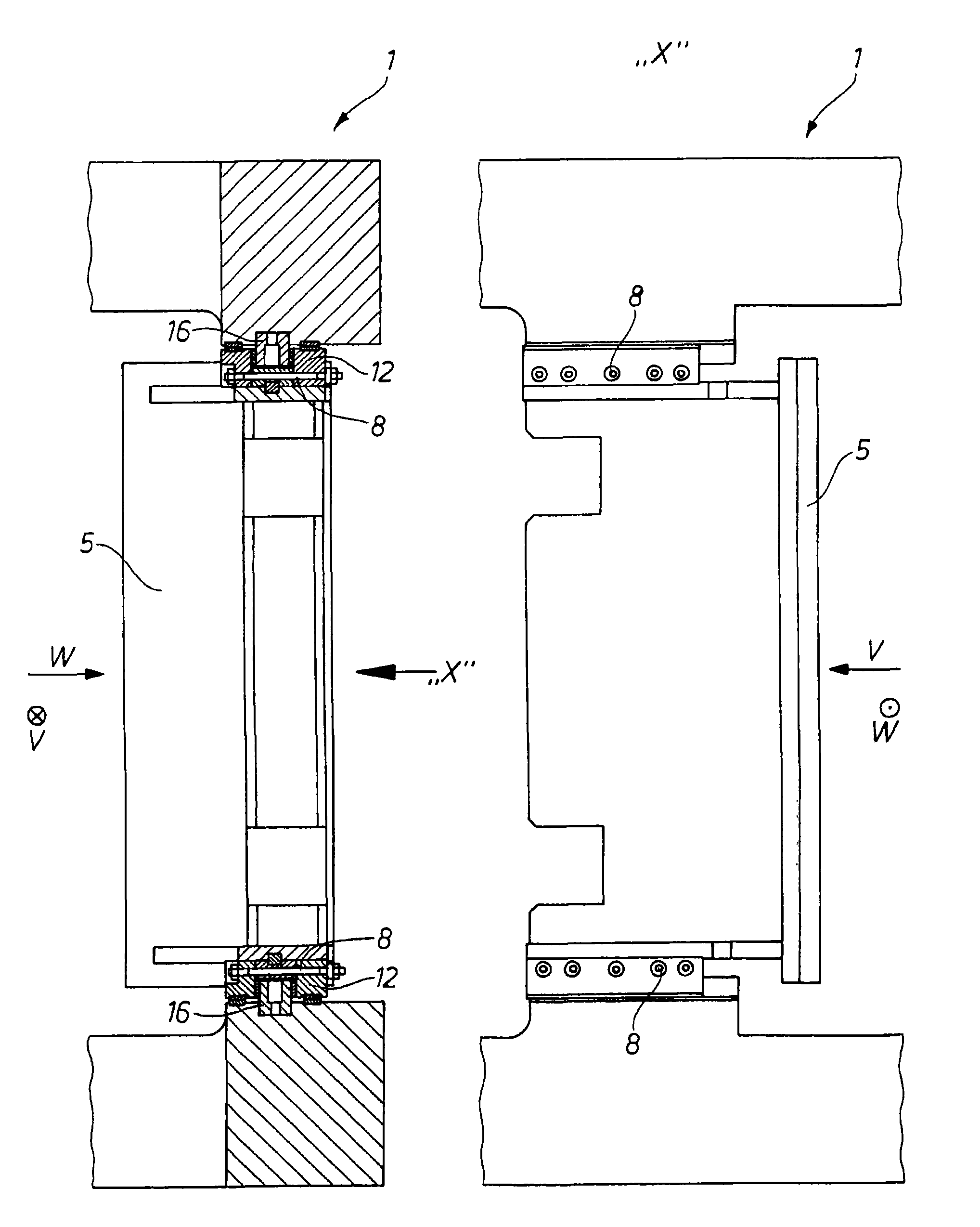

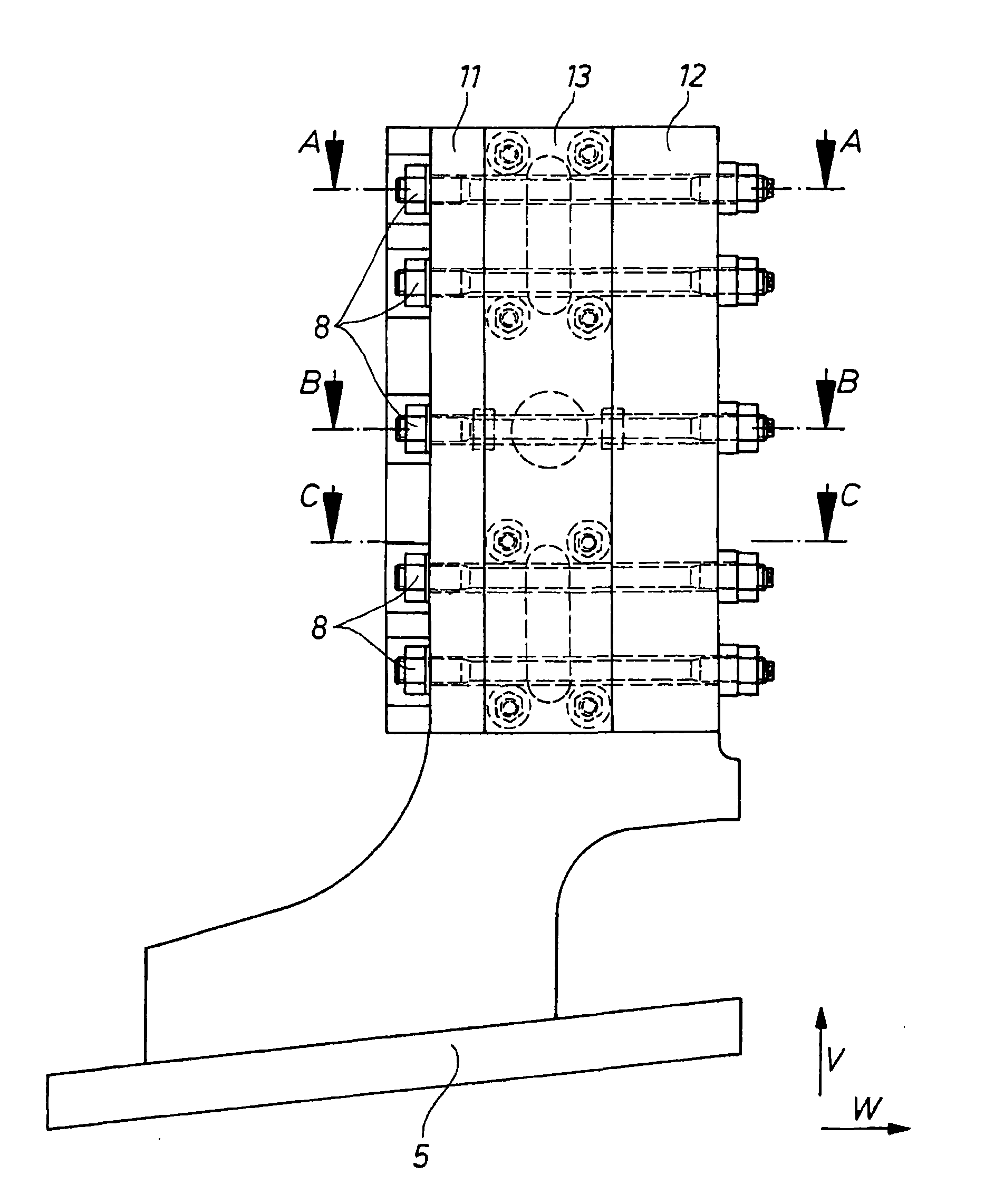

[0021] exist figure 2 shown in the figure 1 The section D-D in the and figure 1 Compatible top view. Here again the output guides 4 , 5 are shown together with their lateral guides, so that the output guides can be adjusted in the vertical direction V or can be moved.

[0022] Support elements 16 , which are designed as elongated rods extending in the vertical direction V, ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com