Method for treating liquid flows at a chemical pulp mill

A pulp mill and liquid flow technology, applied in the regeneration of pulping chemical liquid, washing/replacing pulp treatment liquid, pulping with inorganic alkali, etc., can solve the problems of continuous technical performance doubts and uncommon development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

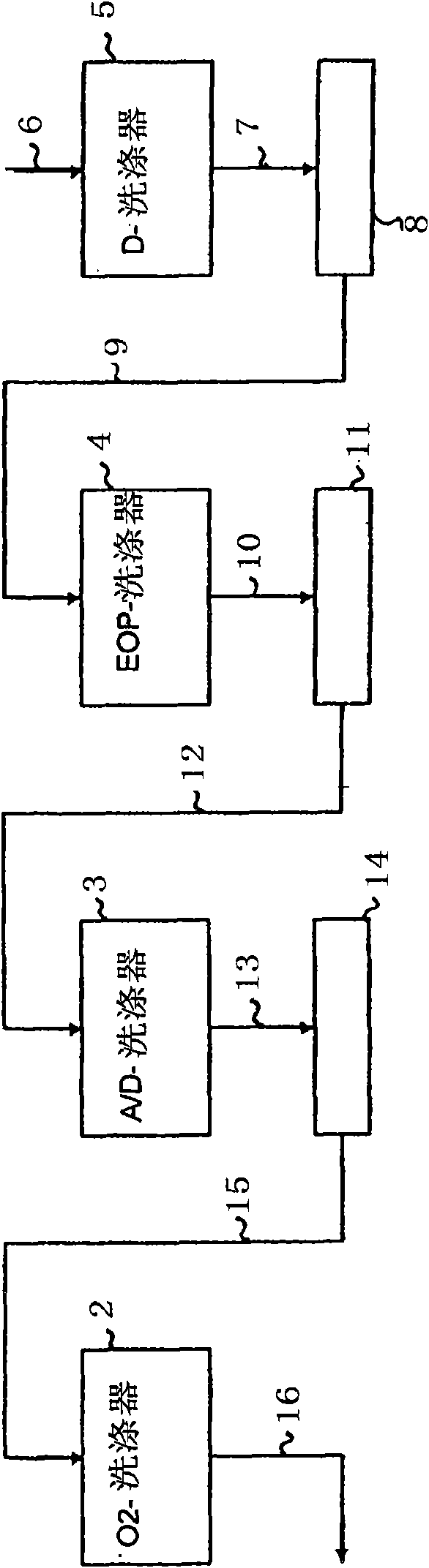

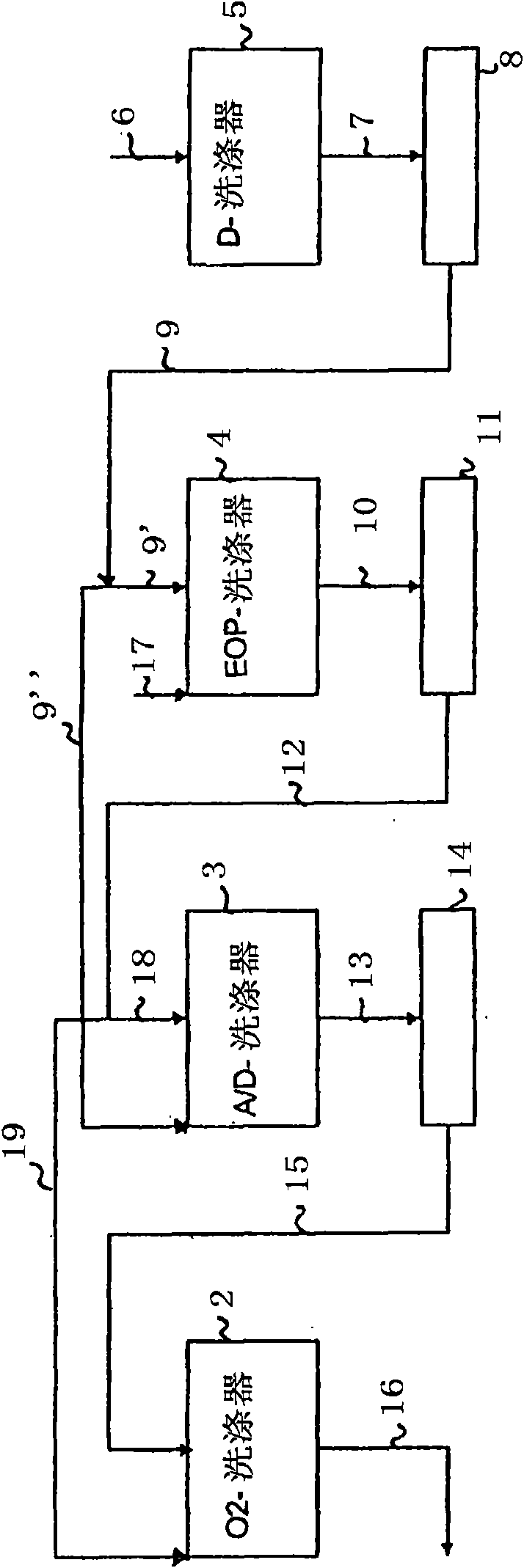

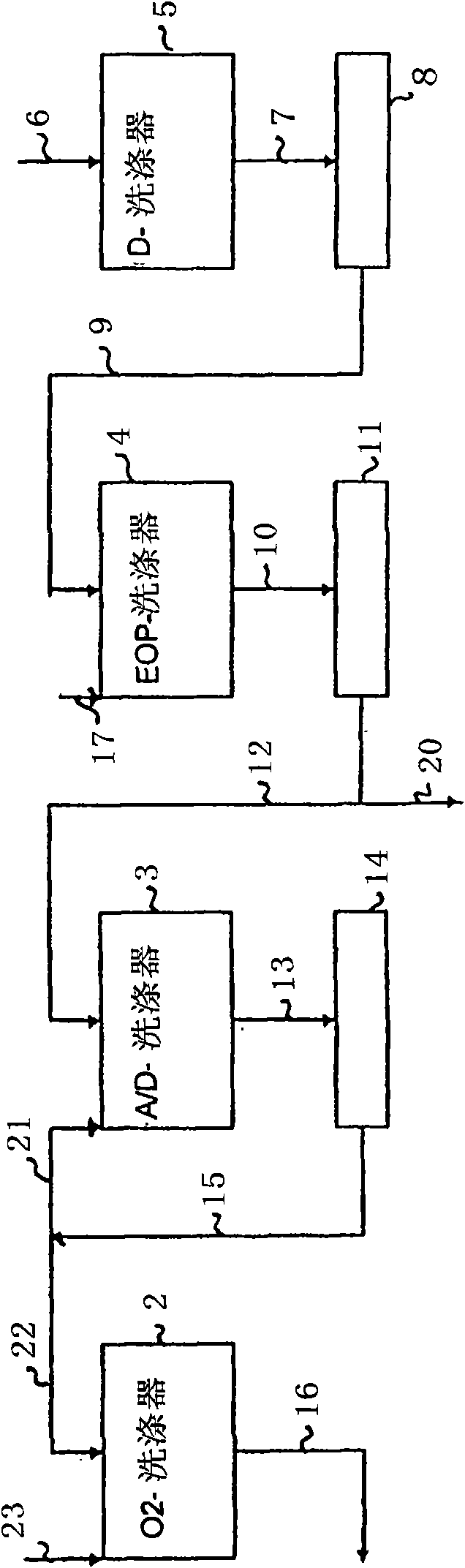

[0103] exist figure 1 The system listed in describes the bleach sequence O-A / D-EOP-D, only the sequence of scrubbers 2-5 is listed. The wash water is passed in reverse with respect to the pulp, and the filtrate originating from each washing unit is treated in a separate purification. Via process line 6 fresh water, or water from a pulp dryer or respectively, is introduced into the washer 5 of the D stage. The wash filtrate is discharged from wash 5 via work line 7 to effluent purification 8 . Scrubber 4 at the EOP stage uses purified water, which flows here via process line 9 . The filtrate produced in scrubber 4 is discharged via line 10 to effluent purification 11 and after this treatment is also discharged via line 12 to scrubber 3 of the A / D stage. The A / D stage scrubber filtrate 13 is treated in purification 14 whereby it is discharged via line 15 to an oxygen stage scrubber for filtrate production, which is also discharged via line 16 to brown stock treatment. Via wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com