Spreading device for spreading out fibre filament bundles, and spreading method carried out using same

A technology of fiber tows and fiber bundles, which is applied in the field of spreading devices, can solve problems such as irregular and irregular fiber distribution, and achieve the effect of flat and uniform spreading and avoiding fiber aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

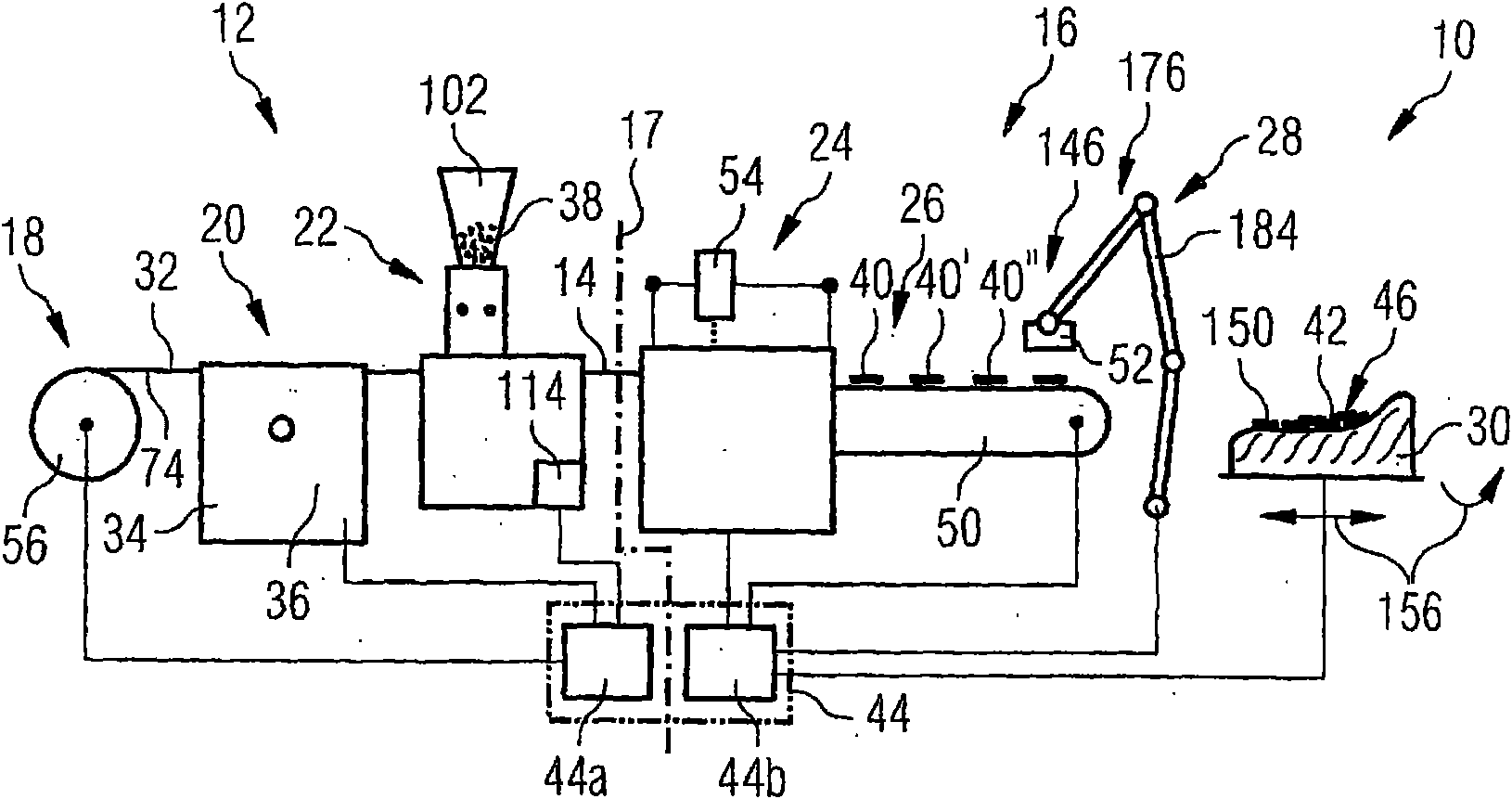

[0037] figure 1 A general view of the preform manufacturing plant, generally indicated by reference numeral 10, is shown. The preform production device allows complex textile semi-finished products to be produced from fiber filaments aligned in the load flow, so that fiber composite structures can be produced in a simple manner even in the case of semi-finished products with complex structures. This textile semi-finished product is called a preform. These preforms consist of individual staple fiber segments held in place by a binder material in accordance with figure 1 Manufactured in advanced equipment, these fiber segments can be pre-cut from specially pretreated fiber tows or fiber tapes. Thus, the preform manufacturing plant may comprise a preparation module 12 for possible preparation of the fiber tape 14 and a cutting and laying module 16 for cutting and laying the fiber tape segments. A possible demarcation 15 between modules 12 and 16 is indicated by a dotted line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com