Flexible double-valve

A beer keg and beer technology, applied in liquid distribution, packaging, distribution devices, etc., can solve the problems of time-consuming and troublesome, and achieve the effect of increasing the sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

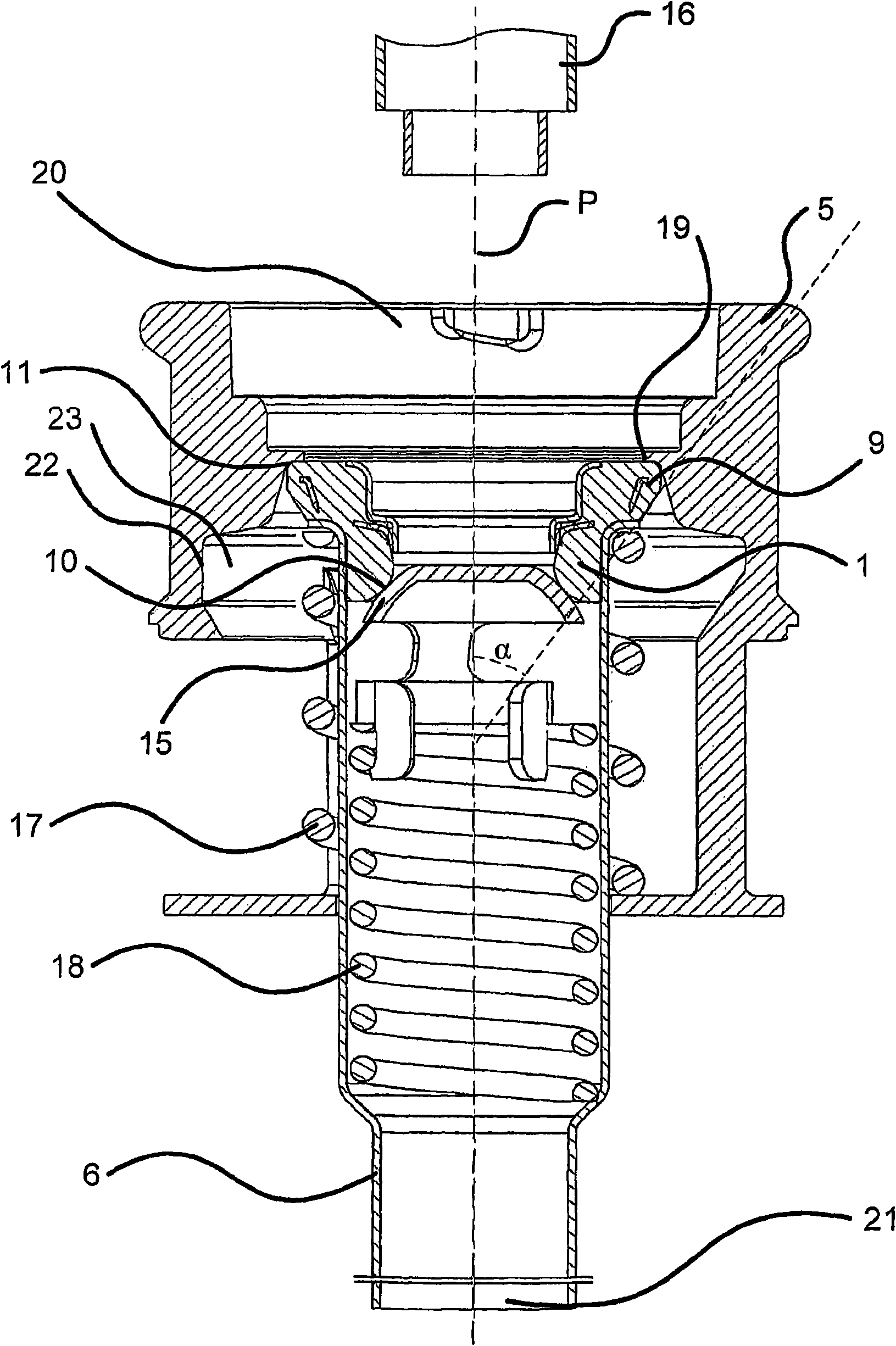

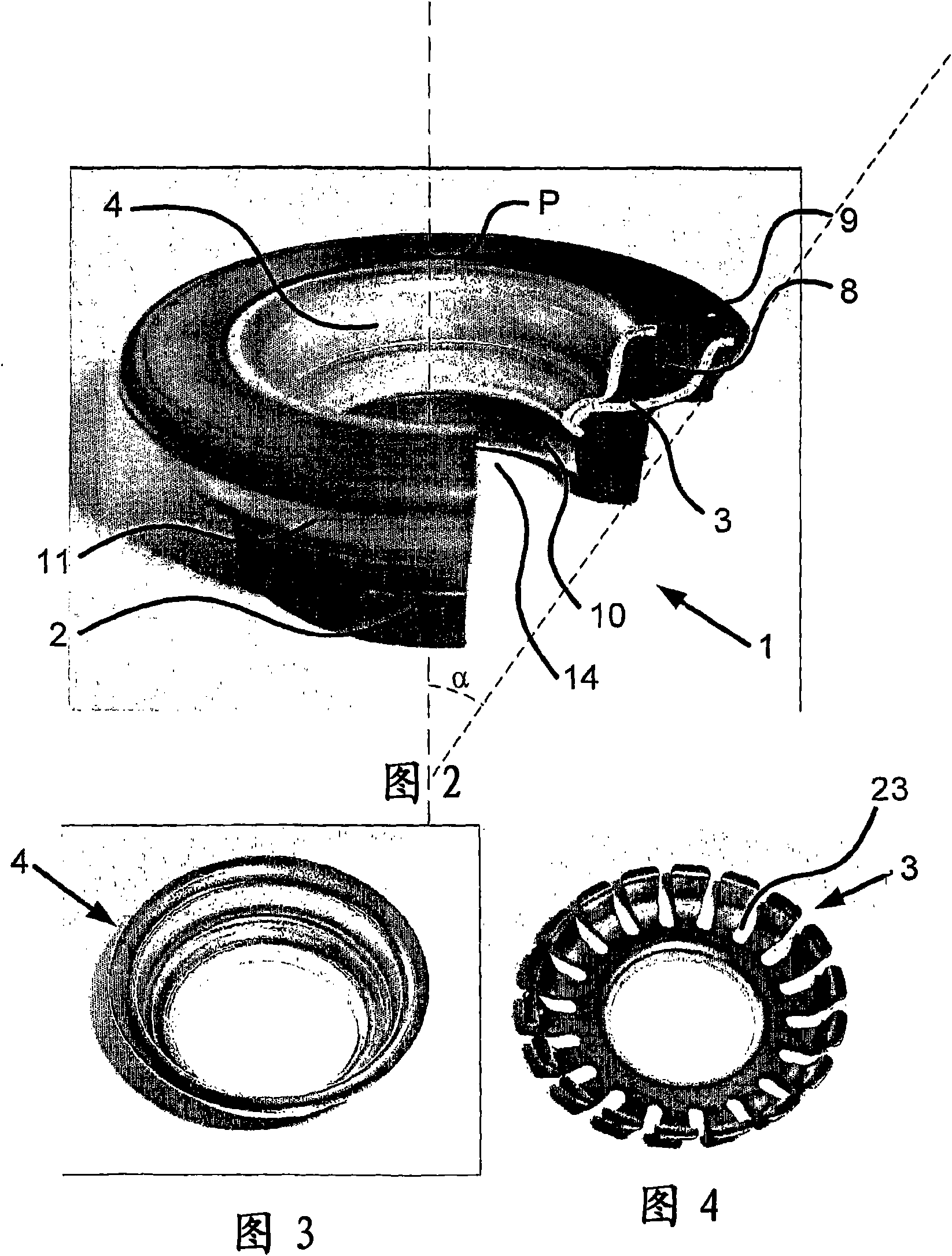

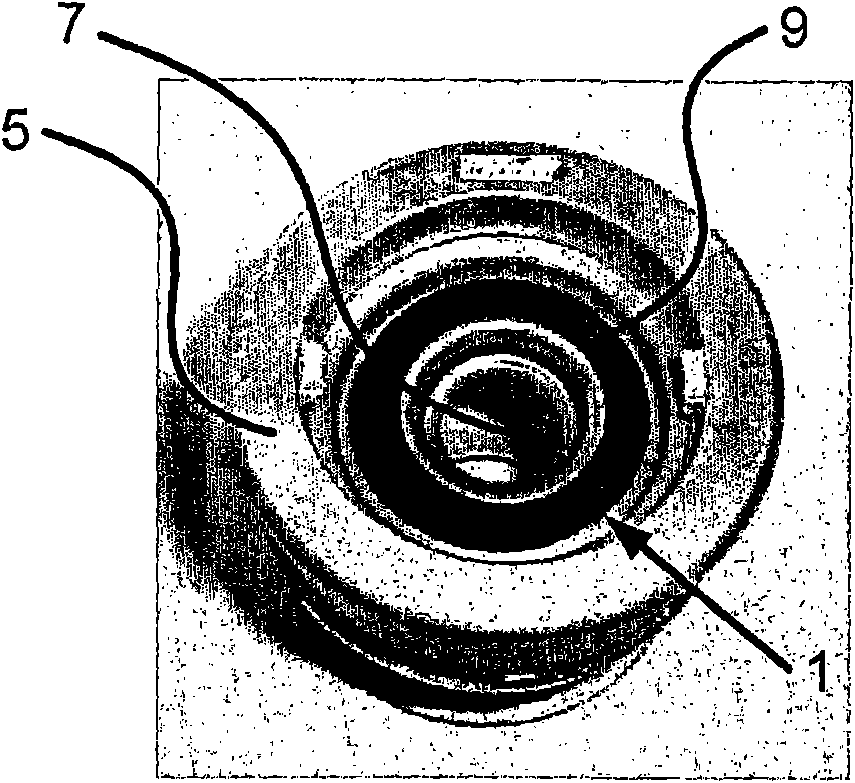

[0032] figure 1 shown inserted into the exemplary fluid pathway 7 (in figure 1A cross-sectional view of a preferred embodiment of the sealing device 1 of the invention not shown in ). The fluid passage 7 is formed by a connection 5 for a beer keg 13 (not shown). Surrounded by the connection piece 5 , the fluid passageway 7 extends from the top 20 of the connection piece 5 along the central axis P of the connection piece 5 to the bottom 21 of the connection piece 5 , allowing fluid to flow through the connection piece 5 . The circumference of the fluid passage tapers from the top 20 of the connector to the opening 19 . From the opening 19 to about the middle part 22 of the connecting part 5, the fluid channel 7 gradually widens, and from about the middle part 22 of the connecting part 5 to the bottom 21 of the connecting part 5, the circumference of the fluid channel 7 gradually becomes smaller. Inserting the sealing device 1 into the middle part 22 of such a connection 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com