Pneumatic tire

A technology of pneumatic tires and tires, applied in the direction of pneumatic tires, special tires, tire parts, etc., can solve the problems of large lateral resistance, comfort that cannot be said to meet the requirements, and cannot be increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

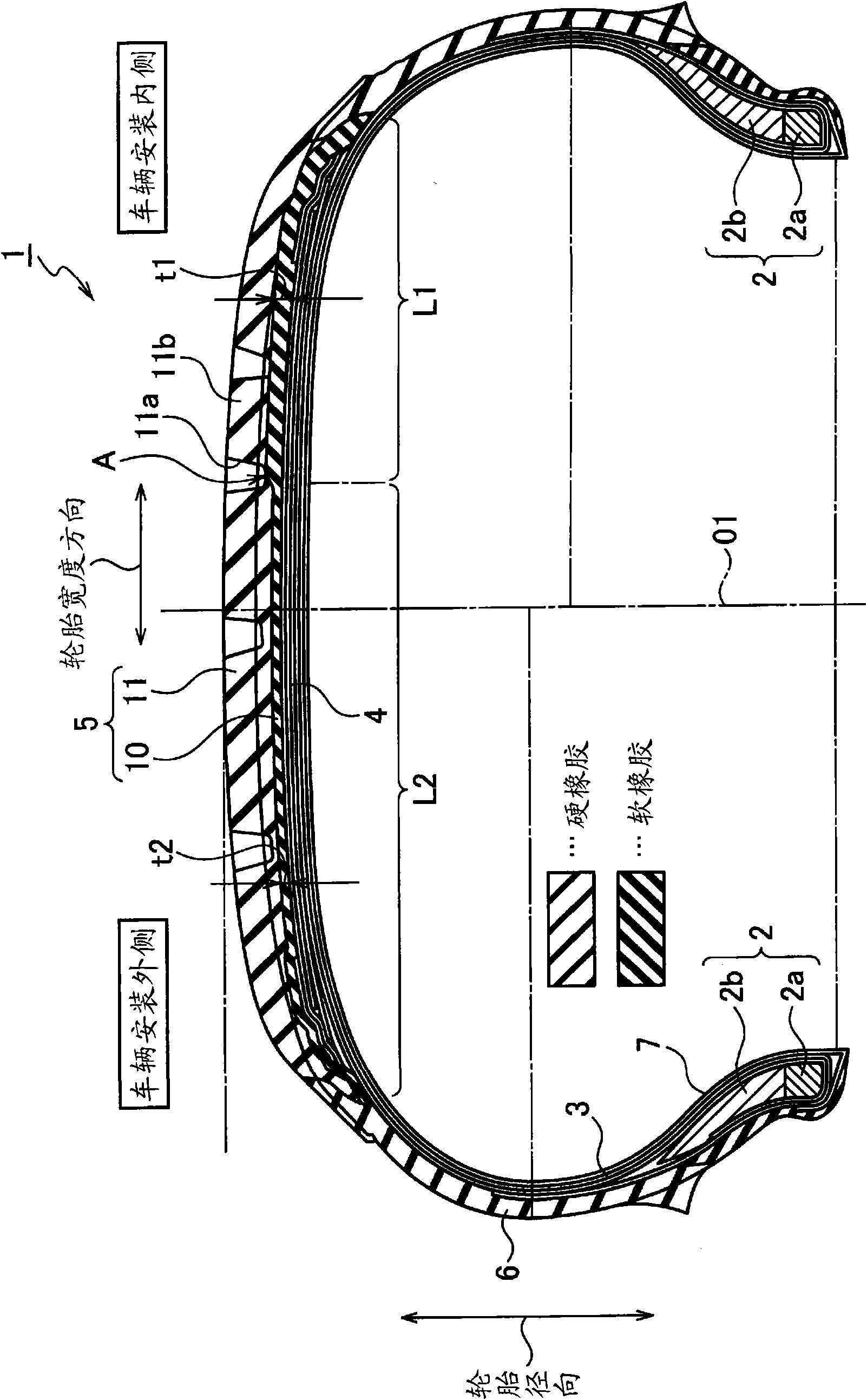

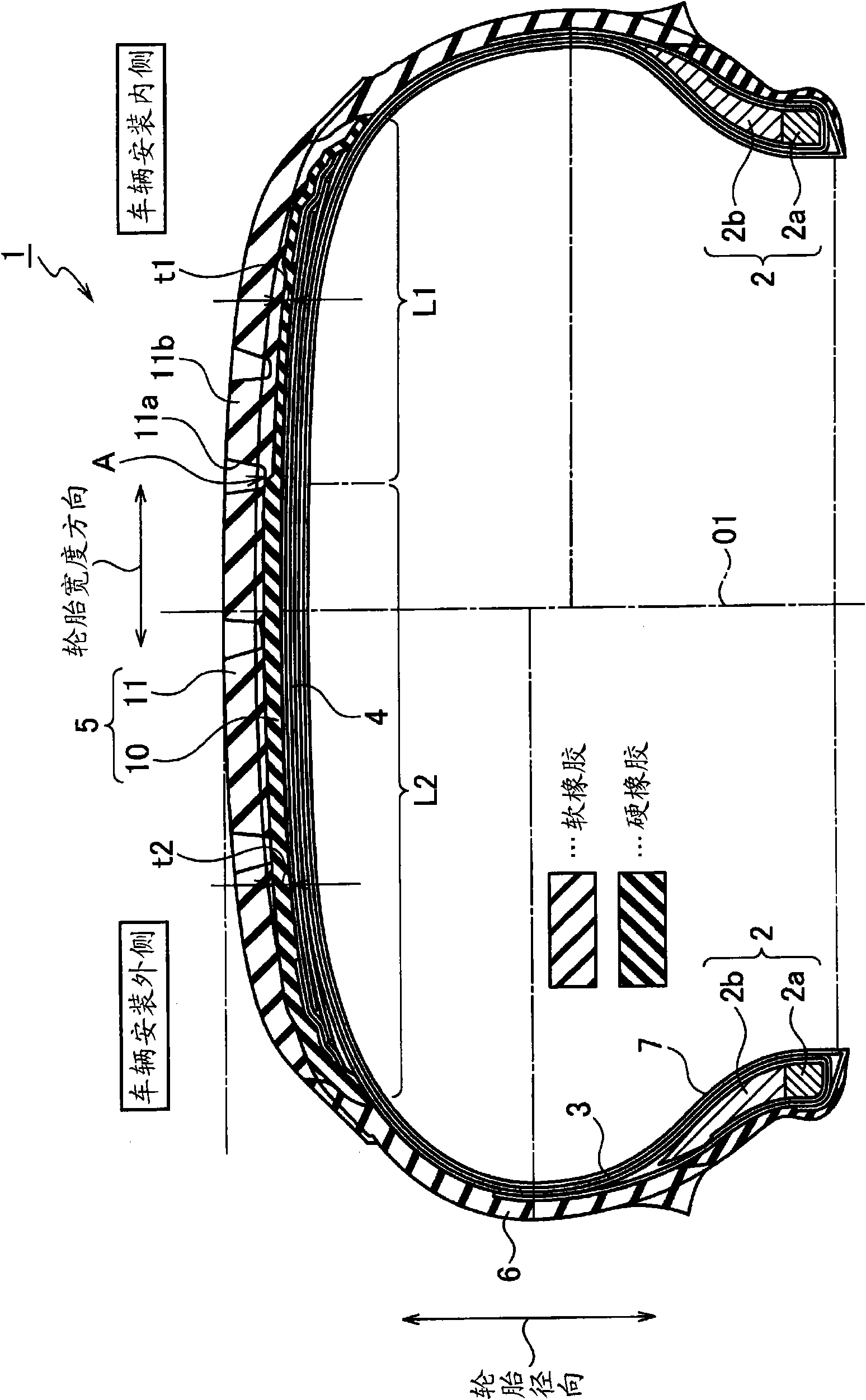

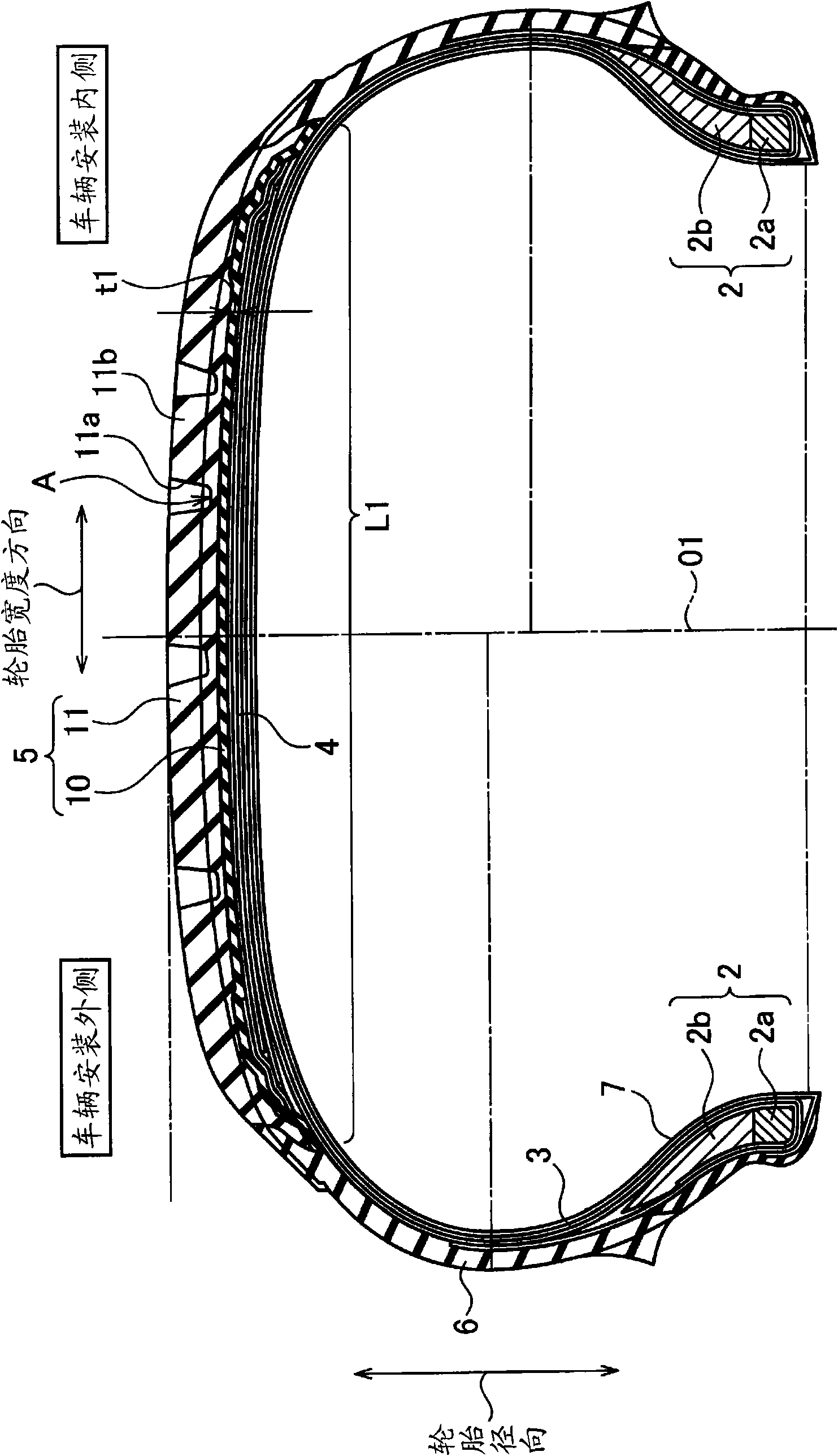

[0051] Next, a comparative experiment to prove the effect of the pneumatic tire of the present invention was performed and described here. The tires used in the experiment were the tires of Examples 1 to 4, the tires of Conventional Examples, and the tires of Comparative Examples 1 to 5 which realized the above-mentioned embodiment. The size of each tire is 225 / 55R17, the rim size is 7.5J×17, and the tire internal pressure is 220 kPa. The test vehicle was Toyota's CELSIOR (trade name), and the number of passengers was 2 (load).

[0052] Such as Figure 4 As shown, in the tire of the conventional example, the tread portion is composed of two layers of rubber, and the thicknesses of the cap rubber and the base rubber are constant over the entire tread. In the tires of Examples 1 and 2 and the tires of Comparative Examples 1 to 3, the tread portion is composed of two layers of rubber, and the tread portion is divided into two sections, the inner section L1 and the outer section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com