Membrane cleaning using an airlift pump

An air lift pump, gas technology, applied in membrane, membrane technology, semi-permeable membrane separation, etc., can solve problems such as the need for ejectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

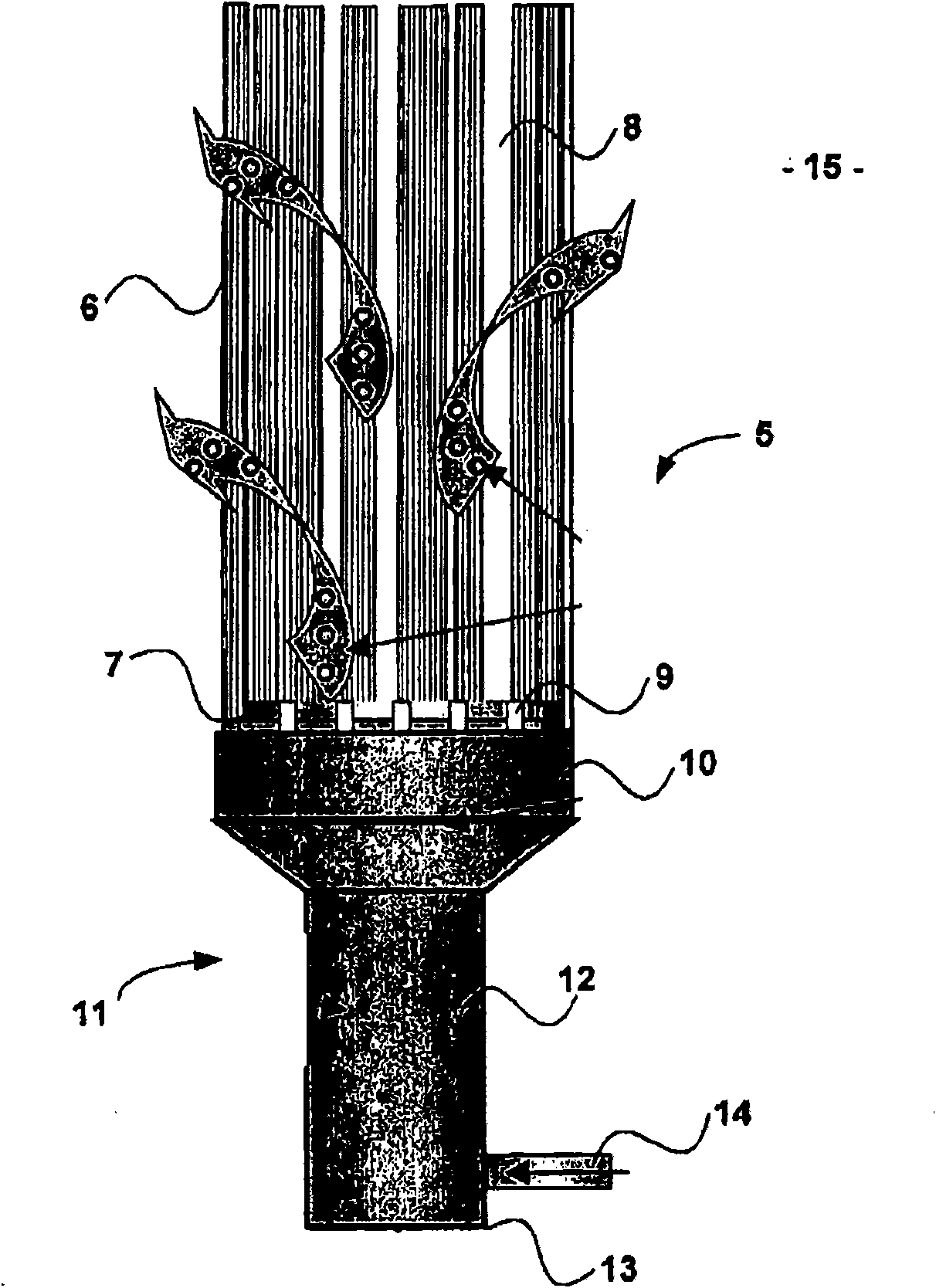

[0027] with reference to the attached figure 1, this embodiment includes a membrane module 5 having a plurality of permeable hollow fiber membrane bundles 6 installed in and protruding from a lower end sleeve 7 . In this embodiment, the bundles are spaced so as to form gaps 8 between the bundles 6 . It should be appreciated that any desired arrangement of membranes within module 5 may be used. A plurality of openings 9 are provided in the lower end sleeve 7 allowing fluid to flow through said openings from a dispensing chamber 10 disposed below the lower end sleeve 7 .

[0028] An air lift pump device 11 is provided below the dispensing chamber 10 and is in fluid communication therewith. The airlift pump unit 11 comprises a pump chamber 12, typically a tube or conduit, open at its lower end 13 and having a gas inlet 14 midway along its length.

[0029] In use, the assembly 5 is immersed in a liquid feed 15 and a source of pressurized gas is applied to the gas inlet 14 at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com