Split stator for electric motor and method for producing the same

一种分瓣定子、制造方法的技术,应用在电动组件、机电装置、电气元件等方向,能够解决寿命缩短、绝缘性能降低、妨碍铁心散热等问题,达到防止温度上升、提高热传导性、确保绝缘性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

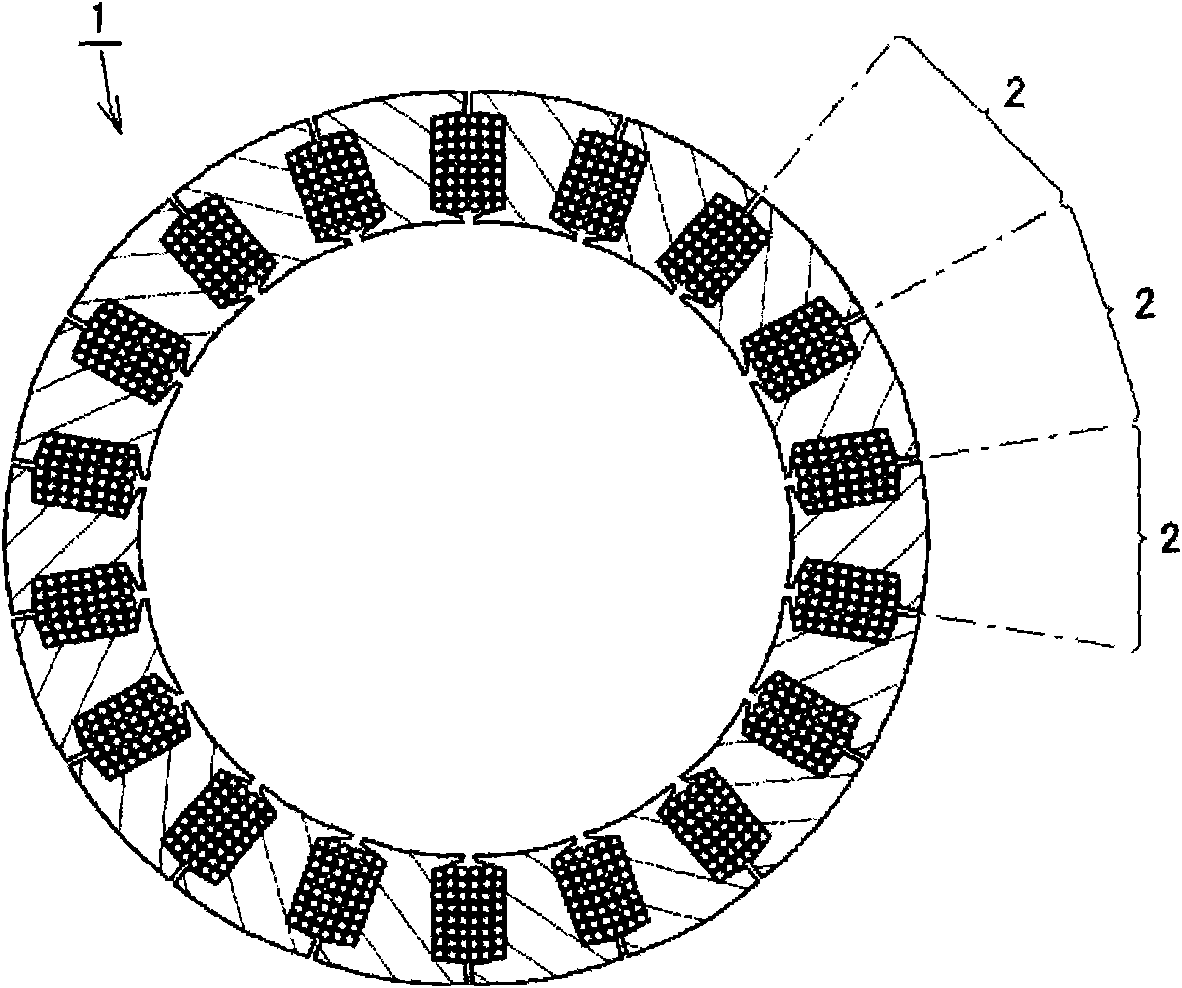

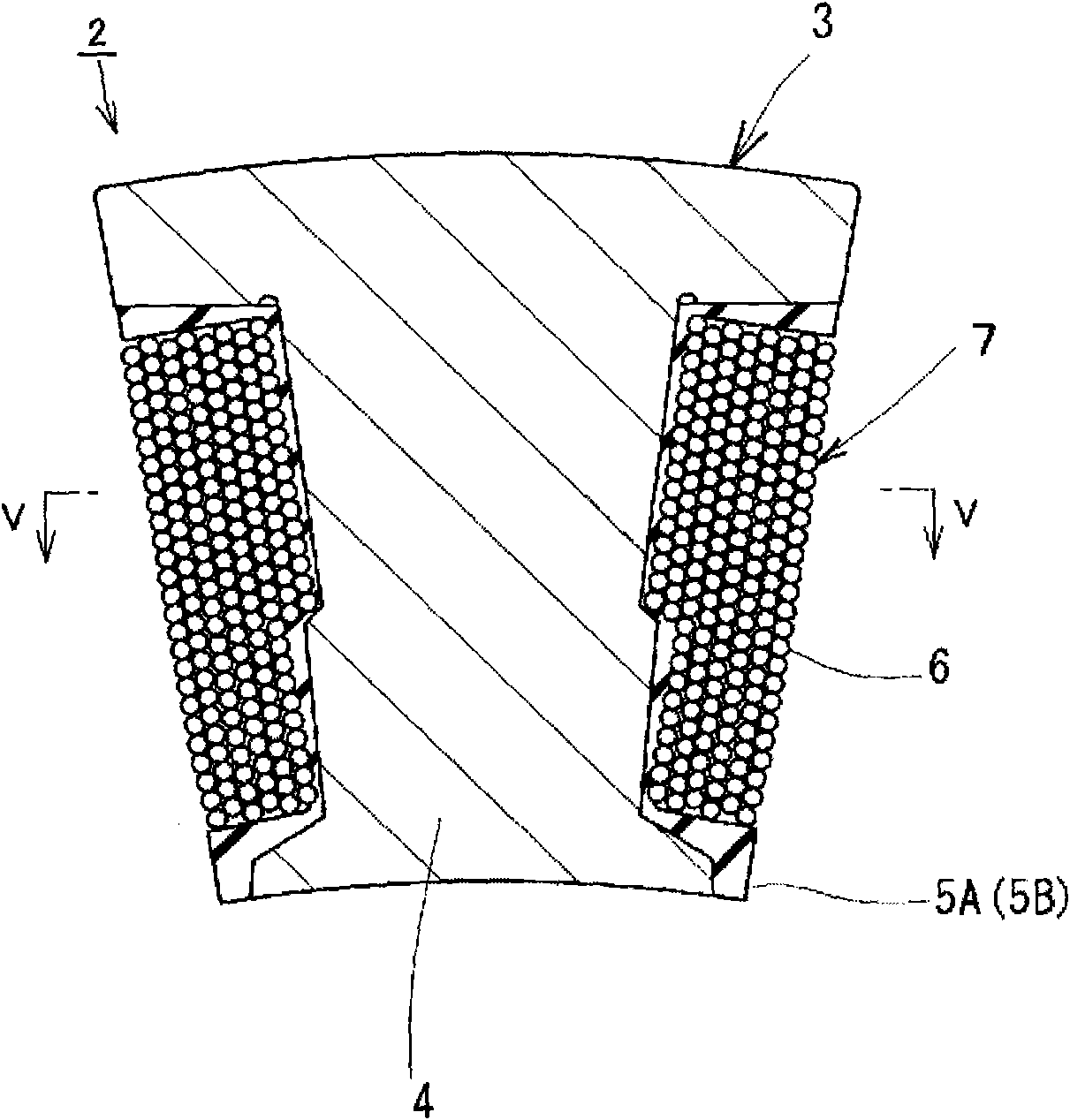

[0043] Such as figure 1 As shown, in this embodiment, the present invention is applied to each split stator 2 of the concentrated winding stator 1 for a motor constituted by combining a plurality of split stators provided with winding bodies into a ring shape.

[0044] The stator 1 is formed by combining a plurality of split stators 2 into a ring shape, and then fixing and assembling the stator 1 so as to surround it from the outside using a ring member (not shown) or the like. That is, the stator 1 is a stator for an electric motor having a plurality of parts connected to each other in an annular shape, each of which has a split stator 2 . A rotor (not shown) provided with permanent magnets is arranged inside the stator 1 to form a motor. In addition, in figure 1 In FIG. 2 , a cross section perpendicular to the axis of the annular shape of the stator 1 is shown so that the overall structure of the stator 1 composed of the split stator 2 can be understood.

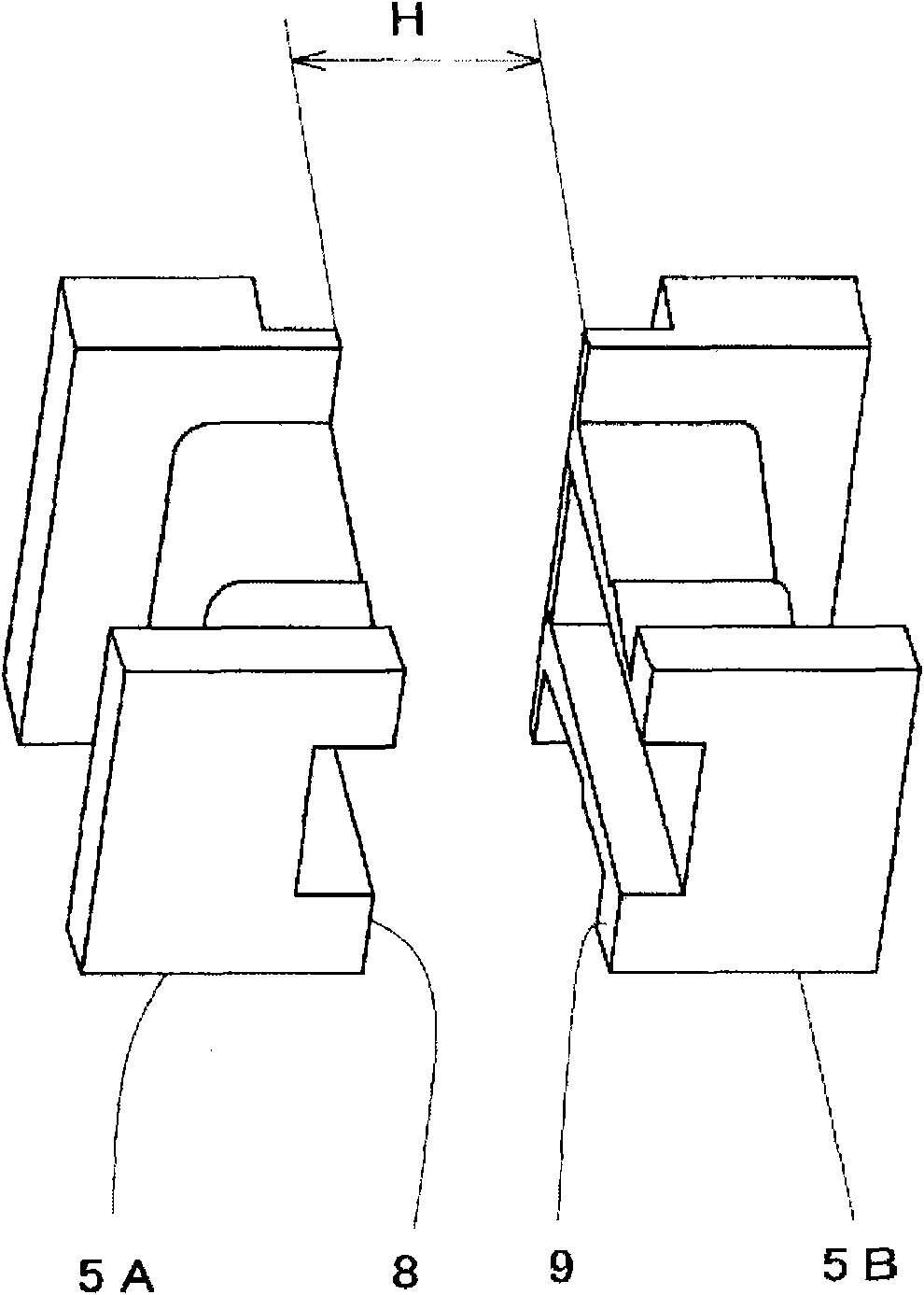

[0045] Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com