Electrical socket of electric heating bag

A technology for electric heating bags and sockets, applied in the installation of base/casing, ohmic resistance heating parts, connecting parts, etc., can solve problems such as low elasticity, achieve safety and service life improvement, simple and reliable fixing, and improve electrical safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

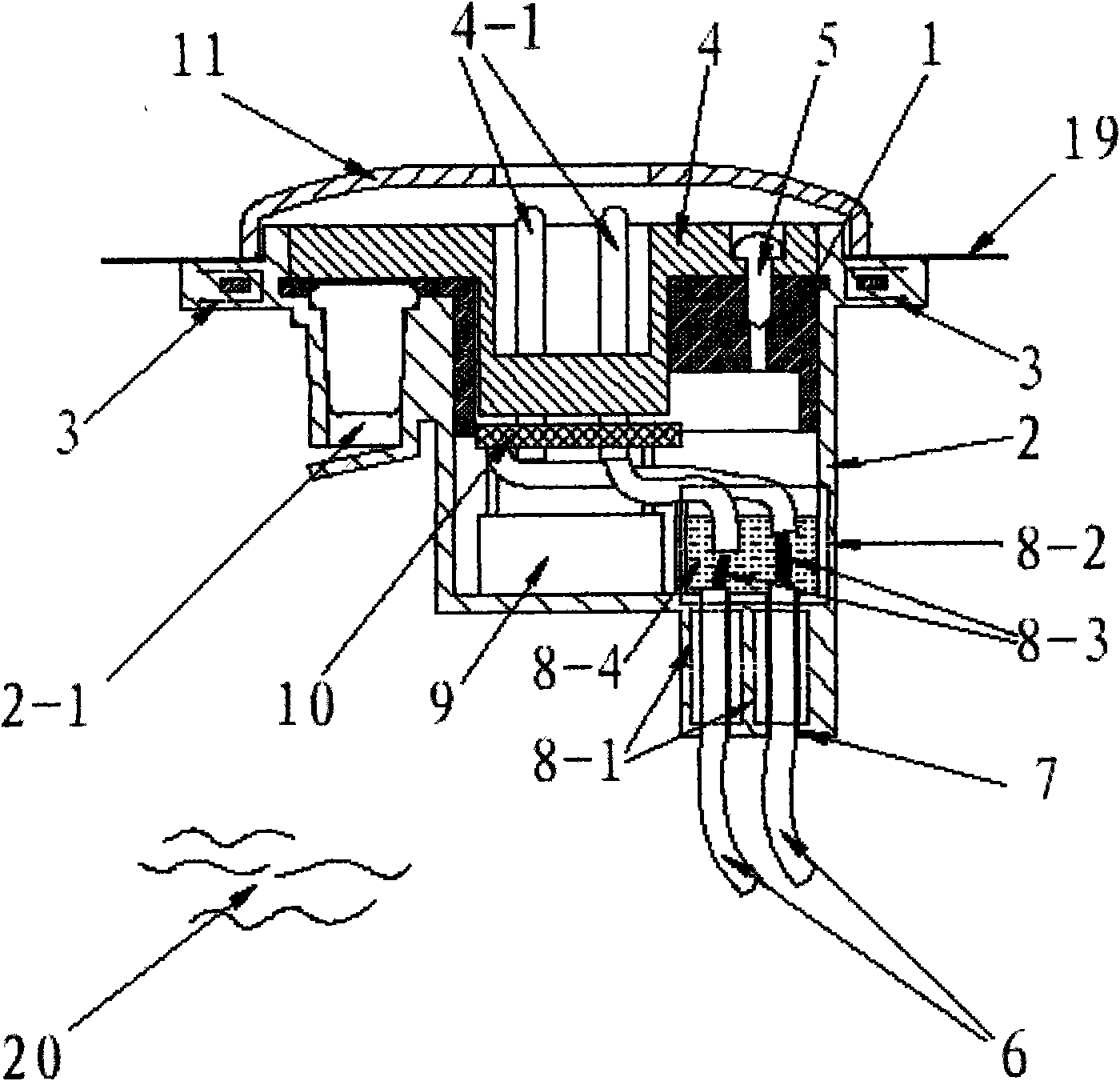

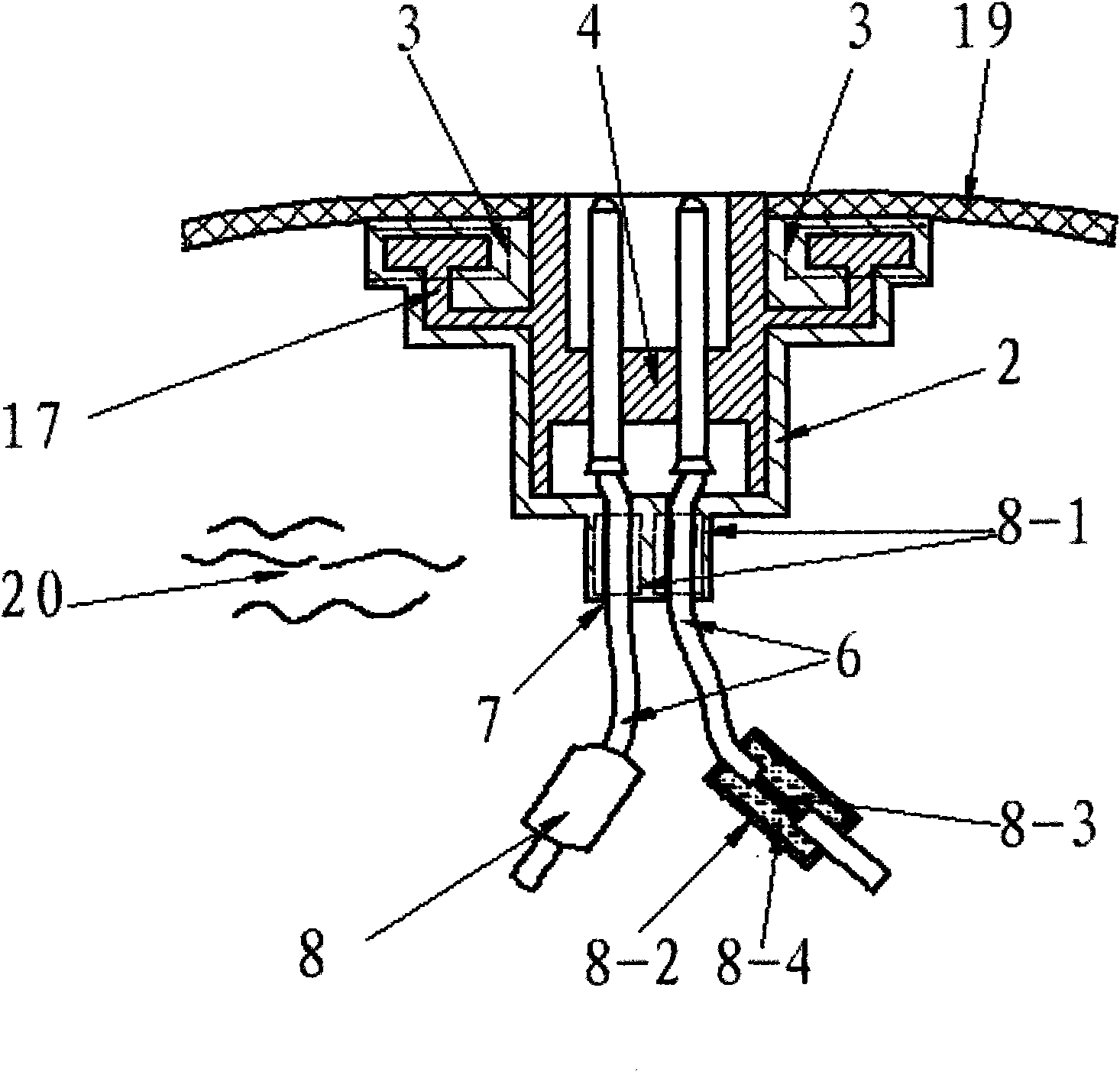

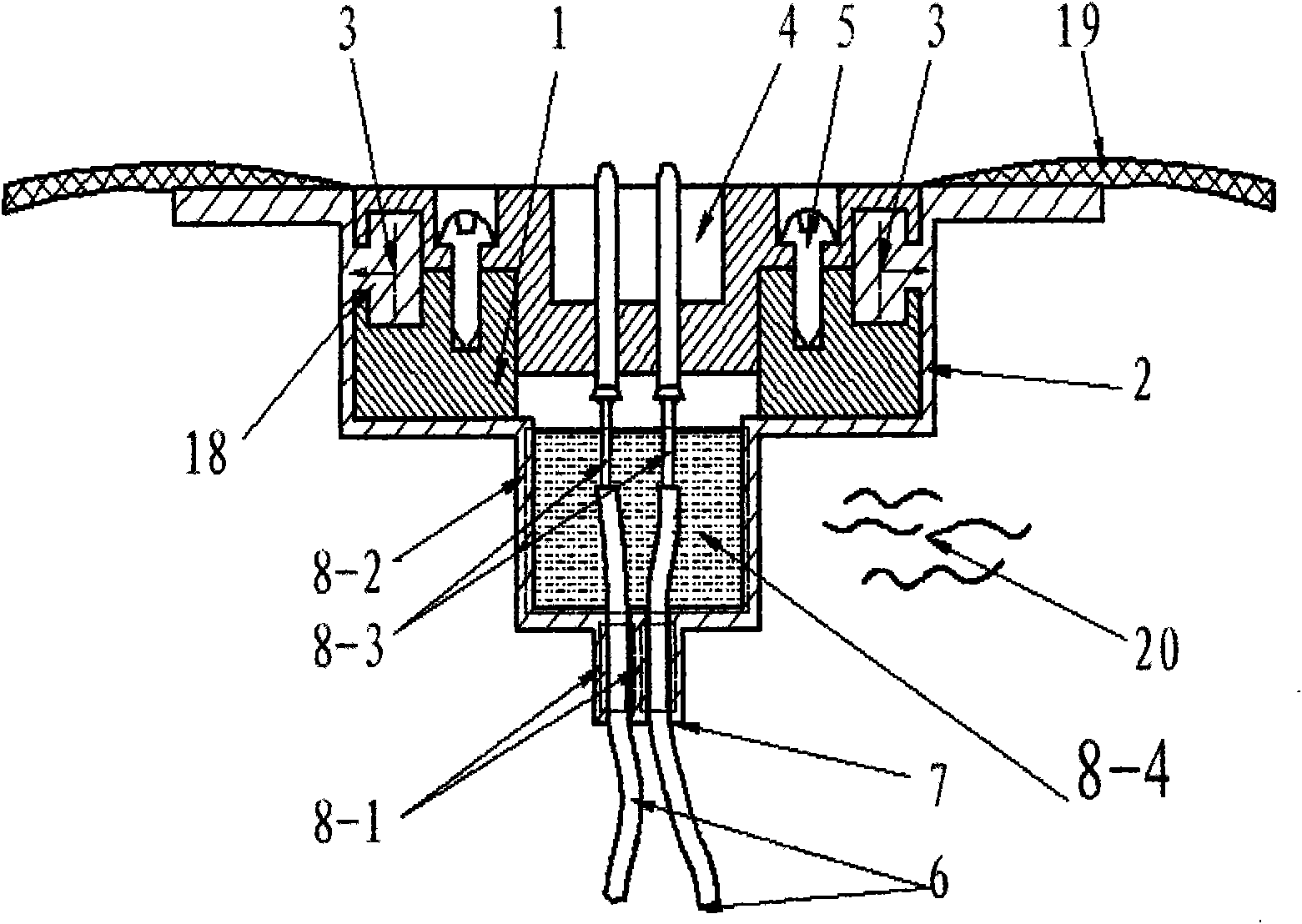

[0041] figure 1 It is a cross-sectional view of a preferred implementation structure of an electric socket for an electric heating bag according to the first technical solution of the present invention. It can be seen in the figure that the fixing part 1 is embedded and connected in the soft spacer 2, and the embedded base material of the soft spacer 2 forms a buckle 3 in the embedded part, and the buckle 3 is vividly marked by a dotted line in the figure. It is marked that the fixing part 1 is provided with holes so that the socket coupler 4 is mechanically connected with it by screws 5; the preferred material of the soft spacer 2 is usually made of PVC that can withstand the temperature of the electric heating bag, and the outer insulation of the wire 6 It is also a PVC material, and the wire 6 passes through the opening 7 of the dry-wet interface of the soft spacer 2. At the opening 7, the PVC material of the soft spacer 2 and the PVC material of the wire 6 are welded toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com