Method for measuring rigidity of poultry eggs

A determination method and technology for poultry eggs, which are applied in the field of physical and mechanical testing of food materials, can solve the problems of lack of relevant literature reports on the measurement of the overall stiffness of poultry eggs, few mechanical properties of poultry eggs, etc., and achieve the effect of avoiding inconvenience and simplifying the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

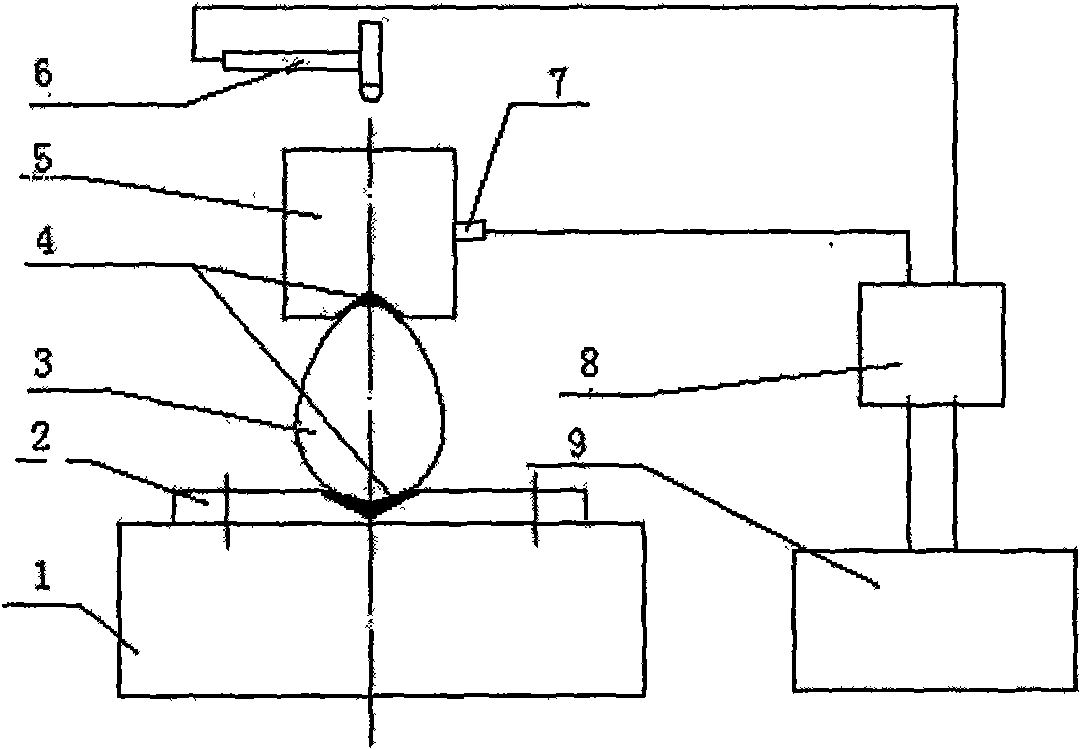

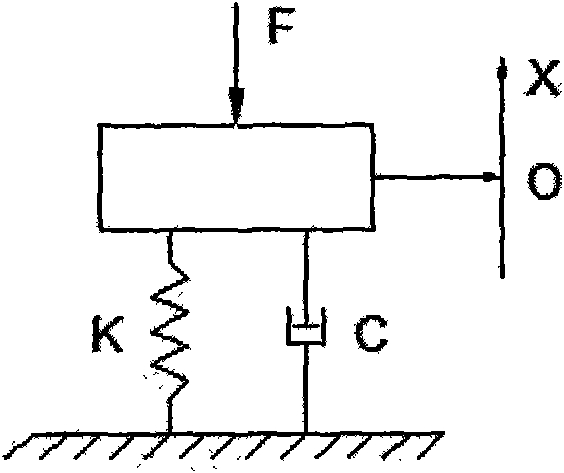

[0018] Take 1 egg sample (75 grams) to be tested, place it upright on the connecting plate of the support platform, and use 502 glue to connect the egg to the connecting plate; place the quality block on the top of the egg, and use 502 glue to connect the mass The block is fixedly connected with the poultry egg; the center of the top of the mass block is hit with a hammer, and the force sensor signal on the force hammer and the acceleration sensor signal on the side of the mass block are converted by a signal converter, and the converted signal is connected to a spectrum analyzer. The spectrum analyzer gives the amplitude-frequency response function curve of the poultry egg, and the natural frequency f of the poultry egg corresponding to the resonance peak o is 569Hz, and finally calculated by the stiffness calculation formula, the egg stiffness is 7.54×10 6 N / m.

Embodiment 2

[0020] Take 1 egg sample (65 grams) to be tested, place it upright on the connecting plate of the support platform, and use 502 glue to connect the egg to the connecting plate; place the quality block on the top of the egg, and use 502 glue to connect the mass The block is fixedly connected with the poultry egg; the center of the top of the mass block is hit with a hammer, and the force sensor information on the hammer and the acceleration sensor signal on the side of the mass block are converted by a signal converter, and the converted signal is connected to a spectrum analyzer. The spectrum analyzer gives the amplitude-frequency response function curve of the poultry egg, and the natural frequency f of the poultry egg corresponding to the resonance peak o is 589Hz, and finally calculated by the stiffness calculation formula, the egg stiffness is 8.08×10 6 N / m.

Embodiment 3

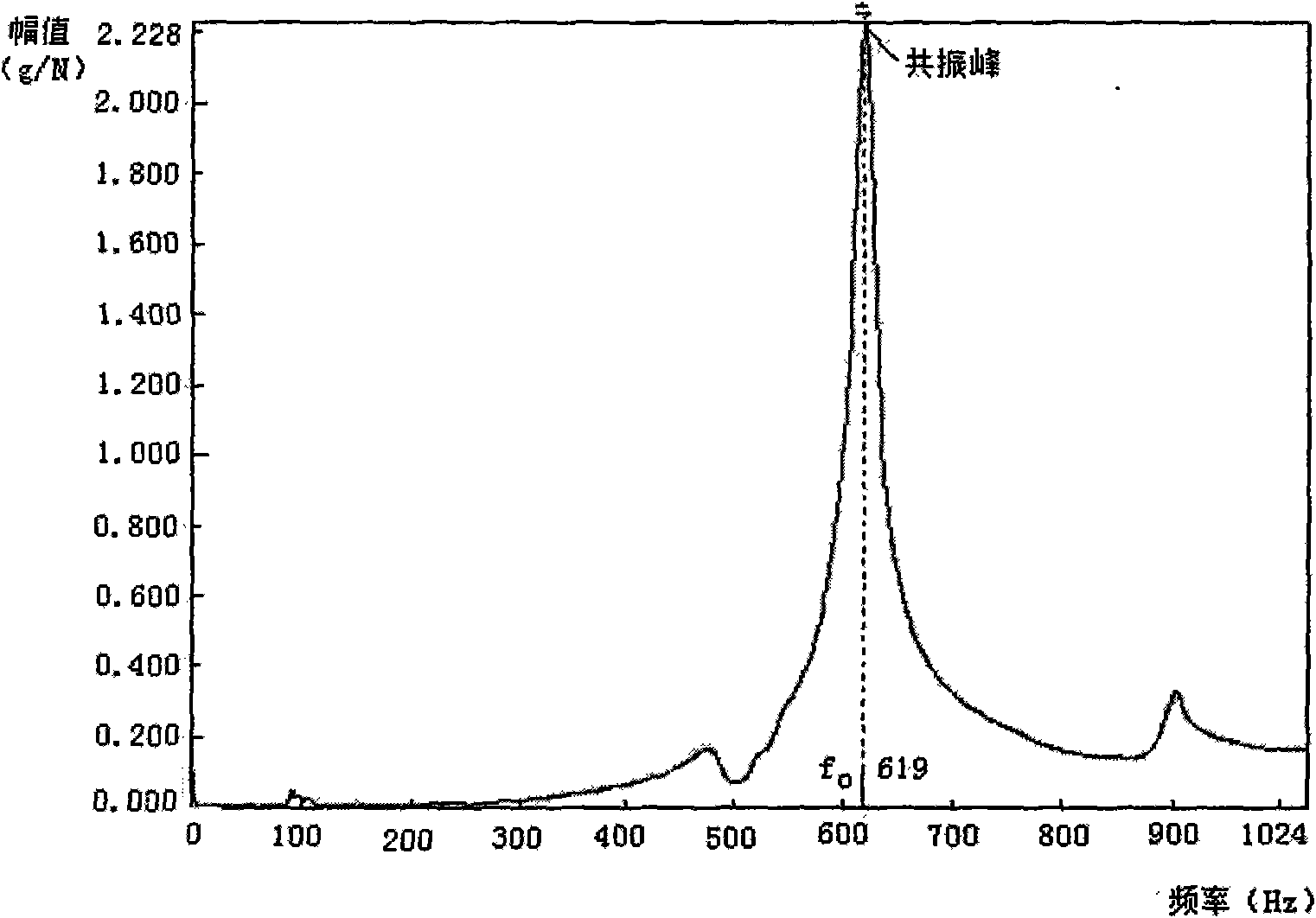

[0022] Take 1 egg sample (55 grams) to be tested, place it upright on the connecting plate of the support platform, and use 502 glue to connect the egg to the connecting plate; place the quality block on the top of the egg, and use 502 glue to connect the mass The block is fixedly connected with the poultry egg; the center of the top of the mass block is hit with a hammer, and the force sensor information on the hammer and the acceleration sensor signal on the side of the mass block are converted by a signal converter, and the converted signal is connected to a spectrum analyzer. The spectrum analyzer gives the amplitude-frequency response function curve of the poultry egg, and the natural frequency f of the poultry egg corresponding to the resonance peak o is 619Hz, and finally calculated by the stiffness calculation formula, the egg stiffness is 8.92×10 6 N / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com