Method and device for near infrared spectral analysis

A technology of near-infrared spectroscopy and analysis methods, which is applied in the direction of material analysis, measuring devices, and analysis materials through optical means, and can solve the problem of limiting the application field of near-infrared spectroscopy analysis systems, not considering changes in working environment temperature, and TEC operating current. and high power consumption to achieve the effect of miniaturization and portability, long working hours and low working current

Inactive Publication Date: 2010-11-10

FOCUSED PHOTONICS +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method has some disadvantages: it does not consider the change of the working environment temperature. If the working environment temperature is quite different from the maximum temperature, such as the working environment temperature is 10°C and the maximum temperature is 50°C, the energy consumption will be high at this time. , long heating time, not suitable for portable analytical instruments

1. In the process of near-infrared spectroscopy analysis, when the temperature of the sample to be tested differs greatly from the specified temperature, for example, the temperature of the sample to be tested is 50°C, and the specific temperature of the analysis system is set to 20°C before leaving the factory. Cooling is required, and the temperature of the sample to be tested is cooled from 50°C to 20°C. At this time, the operating current and power consumption of the TEC are large, which is unacceptable in portable or other applications that require power consumption. Application Fields of Near Infrared Spectroscopy System

2. When the difference between the temperature of the sample to be tested and the specific temperature is large, the temperature adjustment (adjusting the temperature of the sample to be tested to a specific temperature) takes a long time, and compared with heating, the cooling speed is lower and the time is longer. long, not suitable for quick measurements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

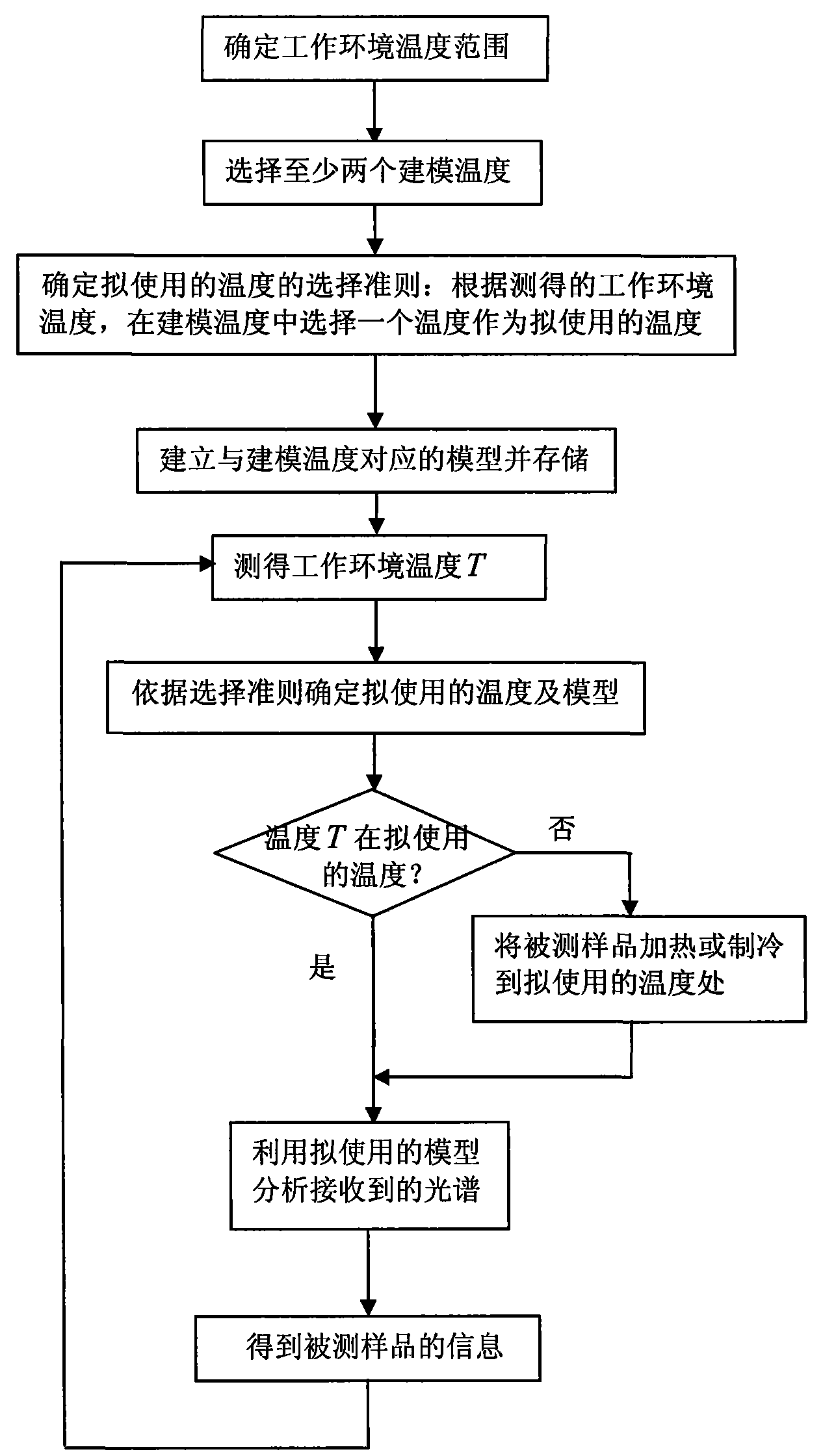

The invention discloses a method for near infrared spectral analysis, which comprises the following steps: a. determining the temperature range of the working environment; b. selecting at least two temperatures as modeling temperatures within the temperature range of the working environment; and determining the selection standard for the temperature to be used; c. establishing and memorizing a model corresponding to the modeling temperature; d. measuring the working environment temperature T and judging whether the temperature T is at the modeling temperature or not; if so, taking the model corresponding to the temperature T as the model to be used; if not, selecting the model to be used according to the selection standard and adjusting the temperature of the sample to be detected to the temperature to be used; and e. measuring the absorption spectrum of the sample to be measured; and utilizing the model to be used to analyze the absorption spectrum obtained by measurement, thus obtaining the parameter of the sample to be measured. The invention also discloses a near infrared spectral analysis device for realizing the method. The method and the device have the advantages of low energy consumption, short consumed time and the like, and can be widely applied to the near infrared spectral analysis.

Description

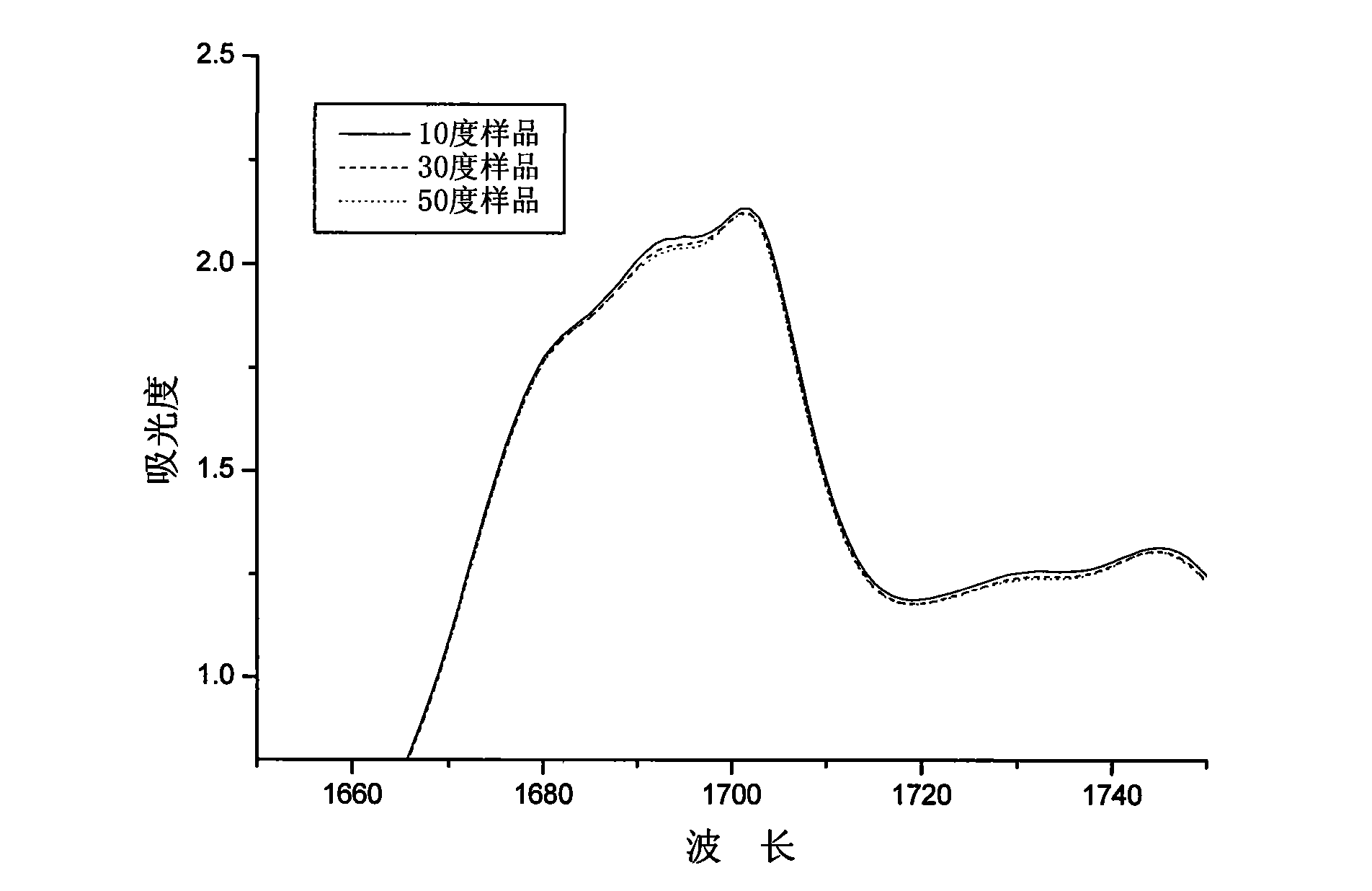

A near-infrared spectroscopy analysis method and device technical field The present invention relates to spectral analysis, more specifically, to a method and device for analyzing samples by using near-infrared spectroscopy. Background technique Near-infrared spectroscopy, such as transmission spectroscopy, is widely used in laboratory and on-site analysis of various liquids for process monitoring and quality control. The basic principle of the analysis is that the measurement light emitted by the light source passes through the liquid sample and is received by the detection module, and the pre-established model is used to analyze the received spectrum to predict the information of the measured sample. Changes in the temperature of the measured sample will change the force between the sample molecules, such as the vibration and rotation of O-H in water molecules will change with temperature, thereby changing the shape of the near-infrared spectrum absorption band or causi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N21/35G01N21/359

Inventor 王健叶华俊冯红年陈英斌

Owner FOCUSED PHOTONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com