Surface form deviation measurement method of flat optical element

An optical element and surface deviation technology, which is applied in the field of surface deviation measurement of flat optical components, can solve the problems of large influence of measurement results, cumbersome process, low measurement accuracy, etc., to reduce manual participation, improve measurement accuracy, and reduce detection. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, but present embodiment is not intended to limit the present invention, and every adopt similar structure of the present invention, method and similar variation thereof, all should be included in the protection scope of the present invention.

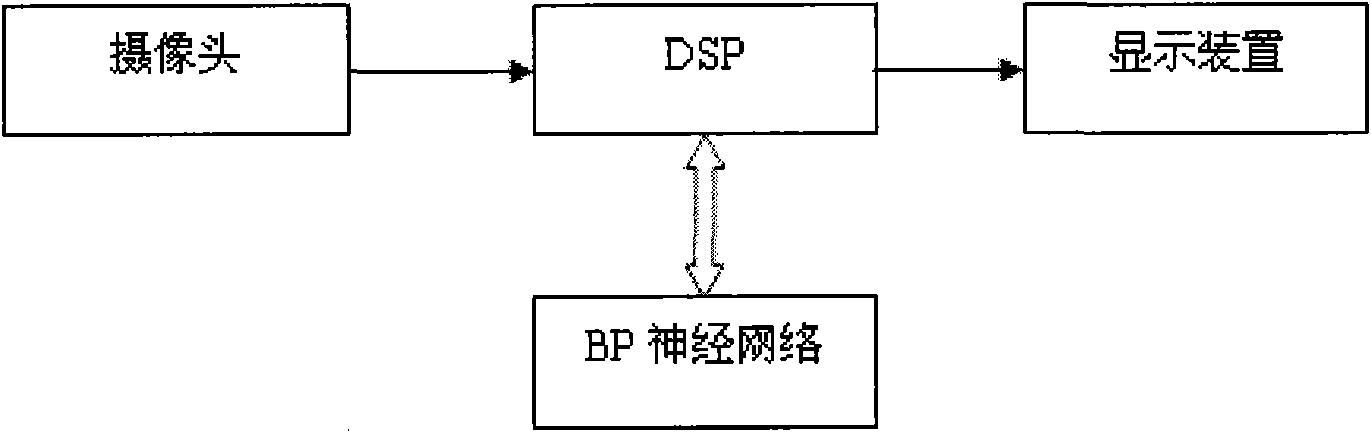

[0033] figure 1 It is a system block diagram of a surface deviation measuring system adopting the measuring method of the present invention. It can be seen from the figure that the surface shape deviation measurement system of the present invention includes: a camera, a digital signal processor (DSP), a BP neural network and a display device.

[0034] The pixel of the camera is 320×240; the DSP adopts TMS320DM642. The display device includes a color graphic dot-matrix liquid crystal display and a monochrome graphic dot-matrix liquid crystal display, and the display device is used to display the processed interferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com