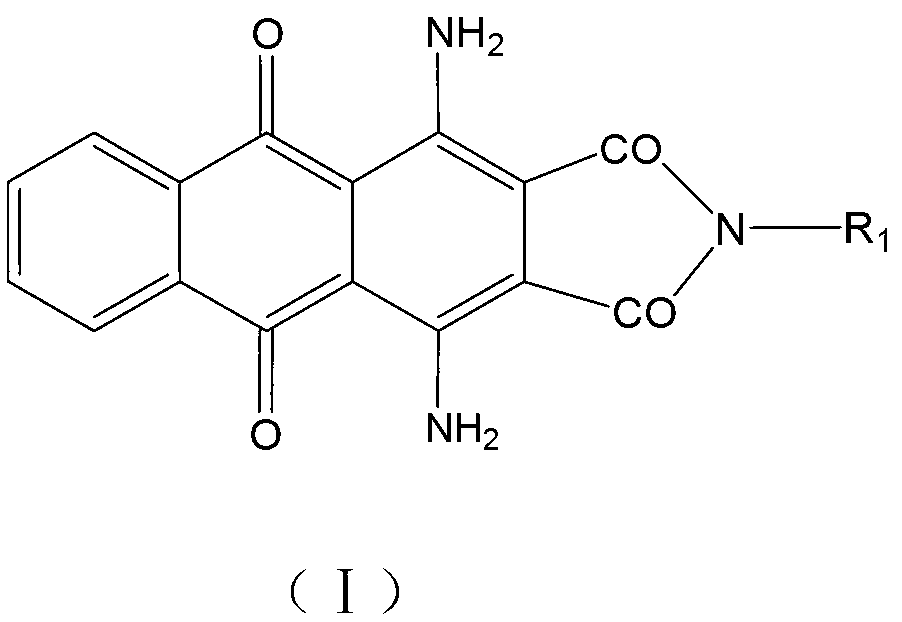

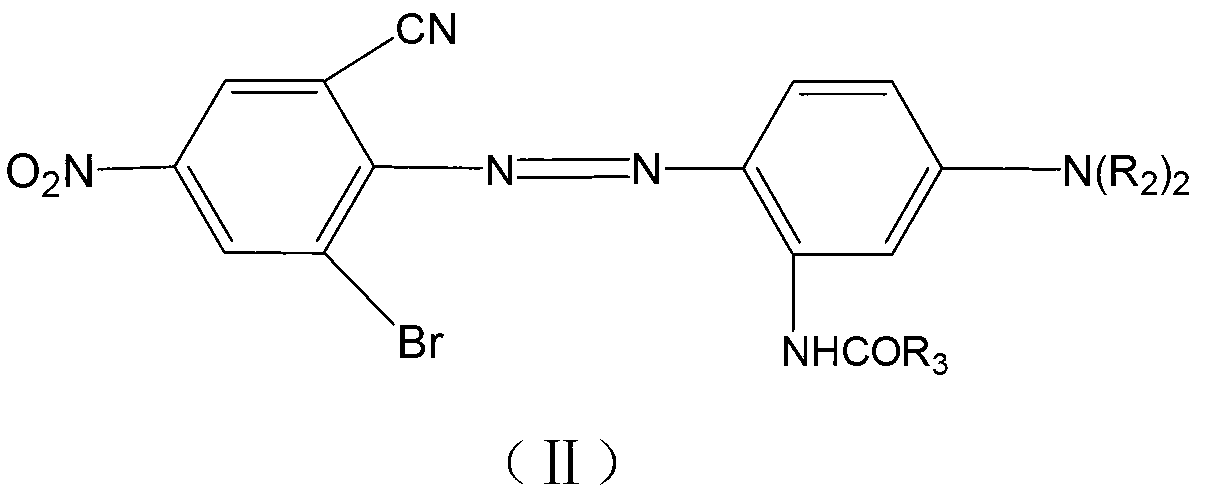

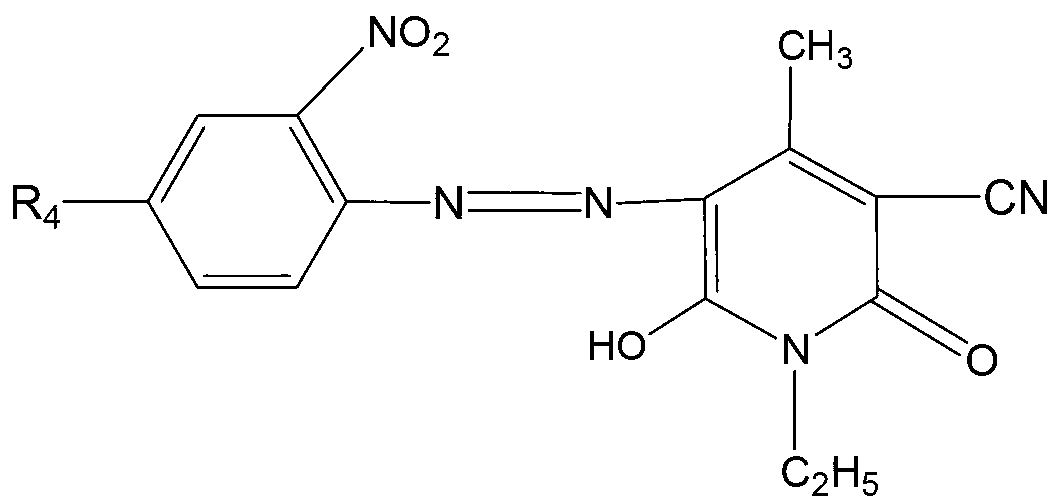

Composition of cobaly blue dispersed dye

A dye composition and disperse dye technology, applied in the directions of organic dyes, dyeing methods, textiles and paper making, etc., can solve the problems of lower quality of dyed fabrics, low sublimation fastness of dyes, limited use range, etc., and improve the color supply ability. , excellent dyeing performance, the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] After uniformly mixing 28 grams of dye 1, 31 grams of dye 2 and 41 grams of sodium lignosulfonate, a powdery dye composition is obtained. Use it to dye polyester fabrics, the color is bright, and the tone is similar to C.1. Disperse Blue 56.

Embodiment 2

[0052] 10 grams of synthetic raw dye of structure (I-1), 26 grams of dye 2, 2 grams of dye 4, 5 grams of diffusing agent MF, 1 gram of urea, 2 grams of glycerin and 54 grams of water were mixed, and then made into The micronized dye suspension is filtered to obtain a liquid dye composition, which is used to dye polyester fibers with bright colors and similar hues to C.1. Disperse Blue 56.

Embodiment 3~6

[0054] According to the data shown in Table 1, the corresponding dye composition can be obtained after mixing the dye components and the diffusing agent uniformly. It is used to dye polyester fabrics in bright blue.

[0055] Table 1: Dye Composition Table

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com