Packaging case for electro-optical device product, and its manufacturing method

A technology of electron optics and manufacturing methods, which is applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc., which can solve the problems of labor and working hours, poor production pass rate, and unsatisfactory production. To improve the strength, improve the design, and ensure the strength of impact resistance in order to solve problems such as waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings as appropriate.

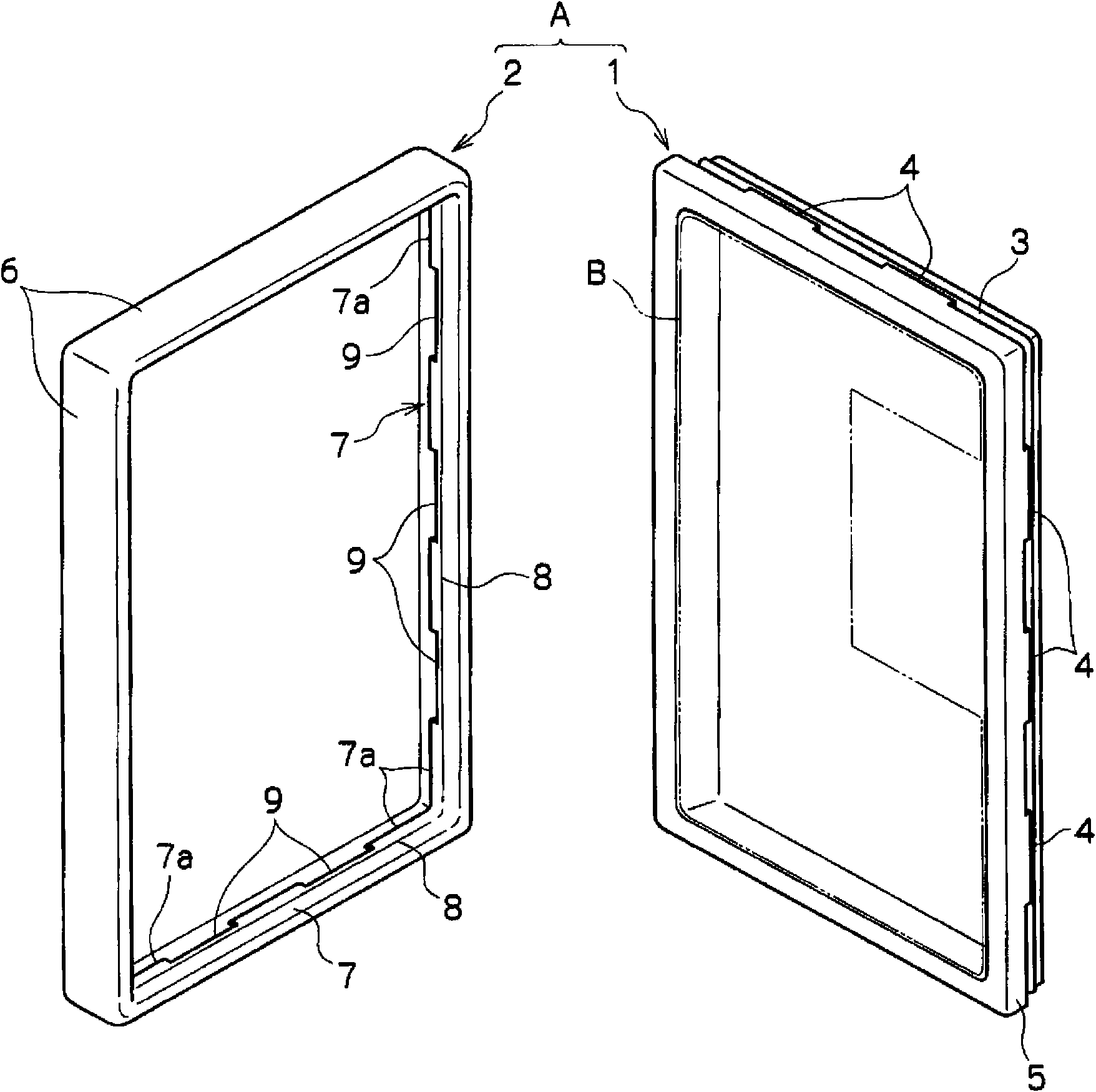

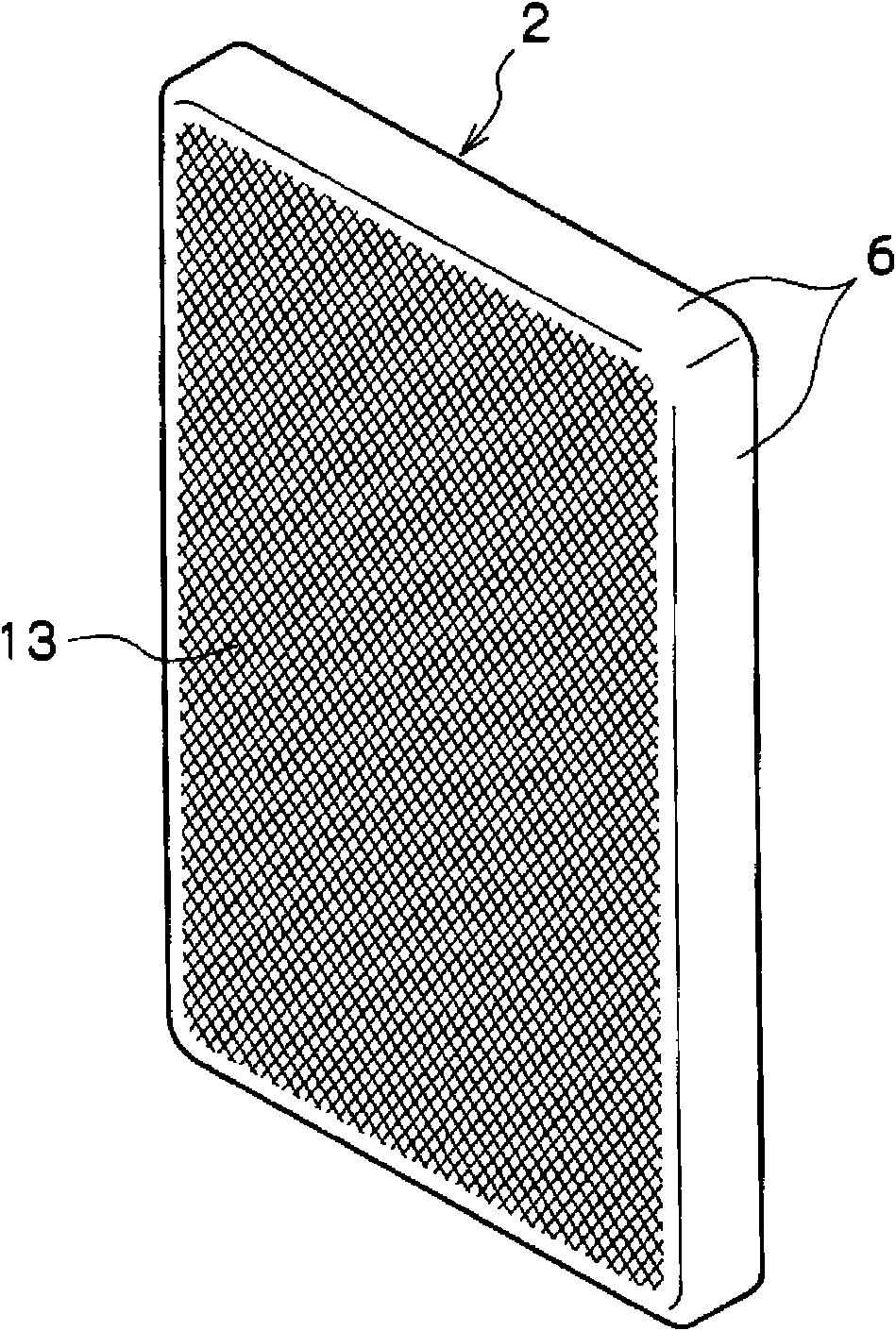

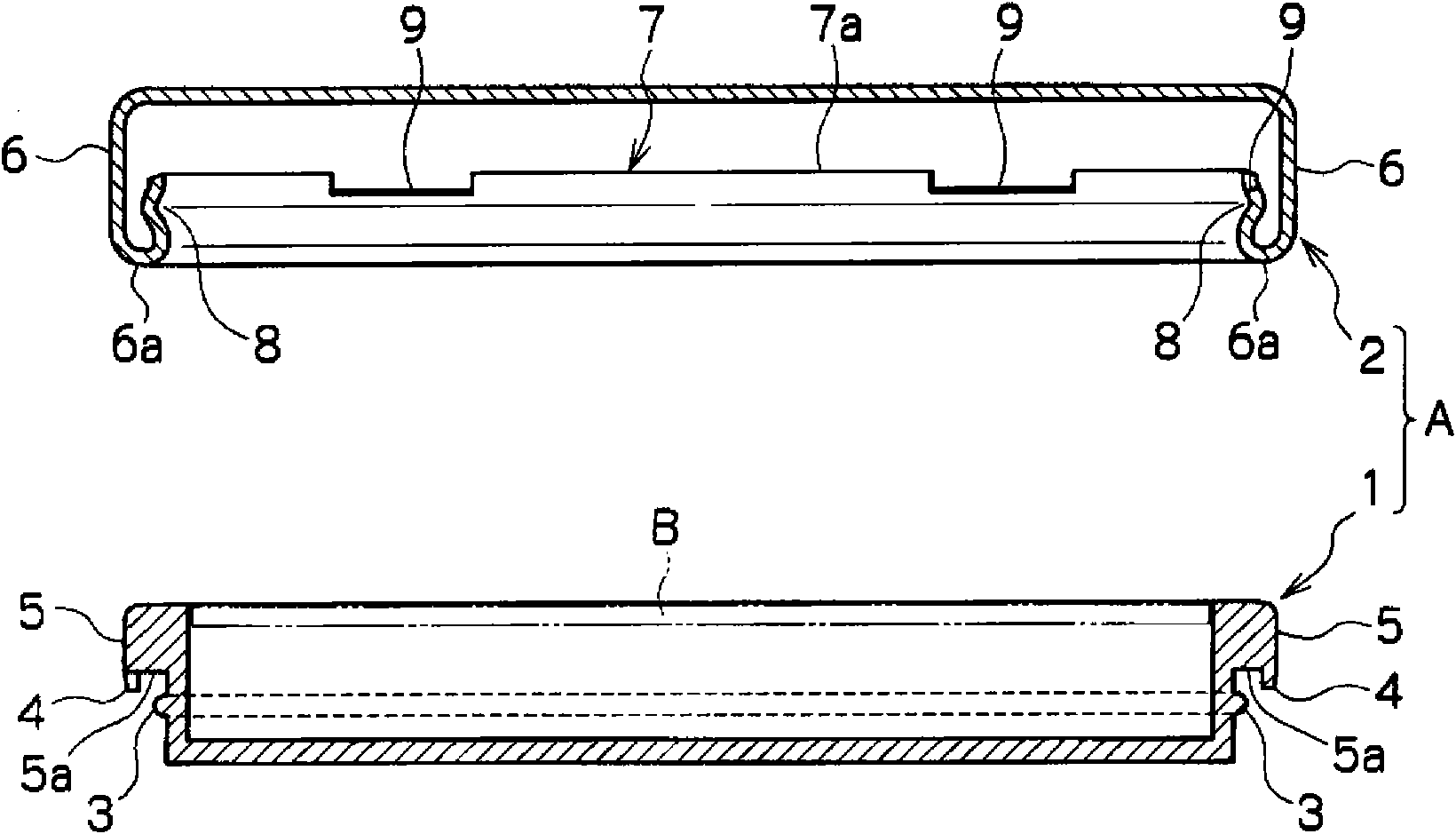

[0048] figure 1 It is each perspective view which shows the state when the main body case and metal case which comprise the exterior case for electro-optical-device products concerning 1st Embodiment are seen from inside, figure 2 It is a perspective view showing the state when only the metal case is viewed from the outside (surface side), image 3 is a cross-sectional view showing the main body case and the metal case, respectively, Figure 4 It is a cross-sectional view showing a state in which a metal case is superimposed and mounted on the main body case by means of an overlay.

[0049] Structure of the exterior case of the first embodiment

[0050] Such as figure 1 As shown, the exterior case A includes: a main body case 1 assembled and built with a substrate B mounted with electronic components;

[0051] The structure of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com