Energy accumulation type hydraulic hole drilling hammer

A down-the-hole hammer and hydraulic technology, used in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc., can solve problems such as small drainage resistance, and achieve large channel cross-section, easy assembly and disassembly, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

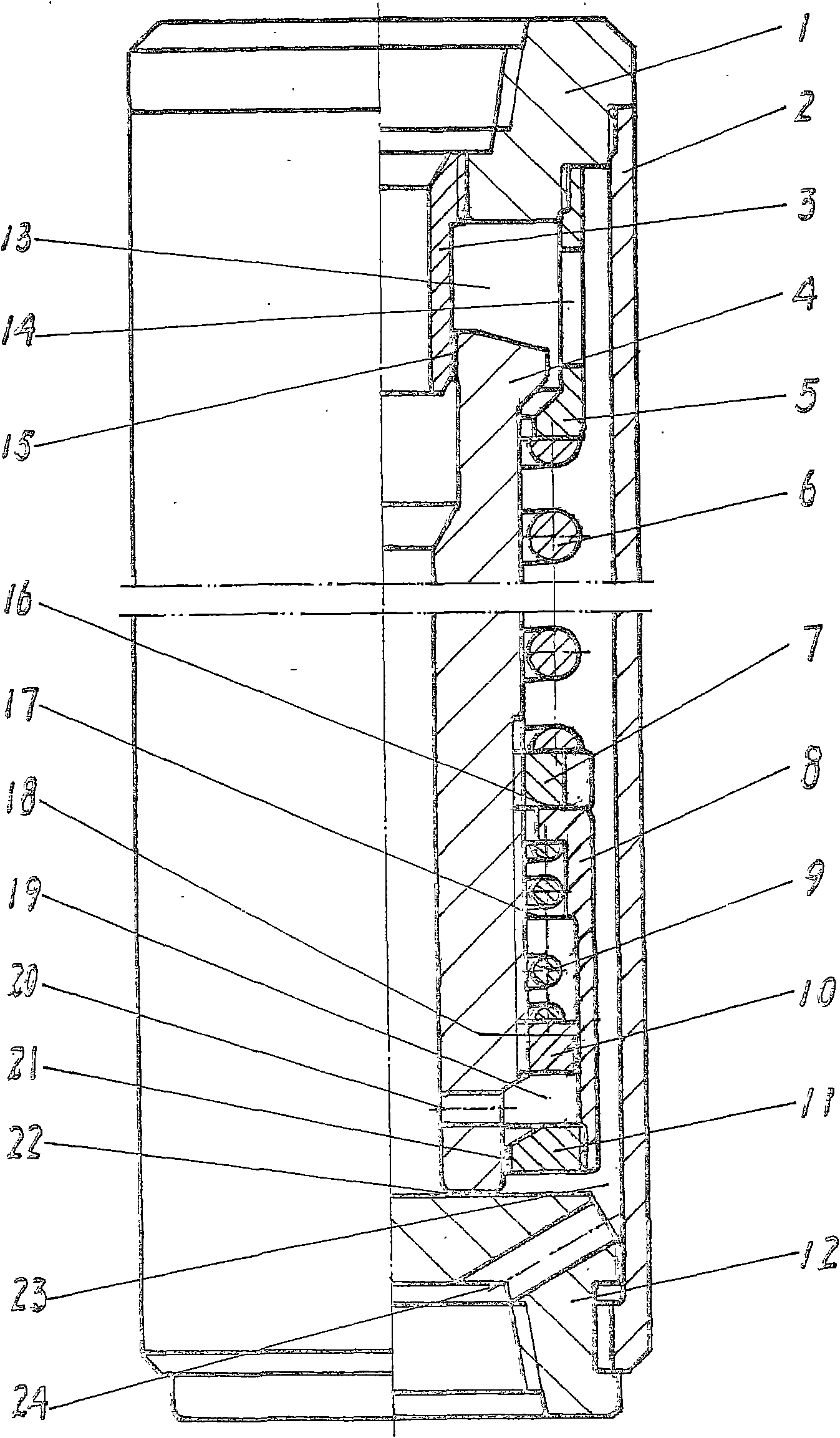

[0014] The energy storage hydraulic down-the-hole hammer such as figure 1 As shown, the upper joint 1, the shell 2, the guide tube 3, the hammer rod 4, the hanger 5, the hammer spring 6, the adjusting nut 7, the cylinder liner 8, the valve spring 9, the piston 10, the valve 11 and the anvil 12, etc. It is composed of parts, and its characteristics are that: the upper part of the shell and the diversion tube are respectively rigidly connected with the upper joint; the center of the hammer rod has a through drilling fluid channel, and the inner wall of the upper section of the channel is sliding and sealingly matched with the diversion tube; the hanger is sleeved on the upper part of the hammer rod To support the hammer rod, the other end is rigidly connected with the upper joint, and there is a liquid hole on the wall of the hanger to connect the upper chamber and the lower chamber in the shell; the hammer spring 6 is set on the upper part of the hammer rod 4, and the adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com