Conveying system of carton cigarette and method

A bar cigarette conveying system and bar cigarette technology are applied in the directions of transportation and packaging, packaging automatic control, single object, etc., which can solve the problems of large investment and large layout duty ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

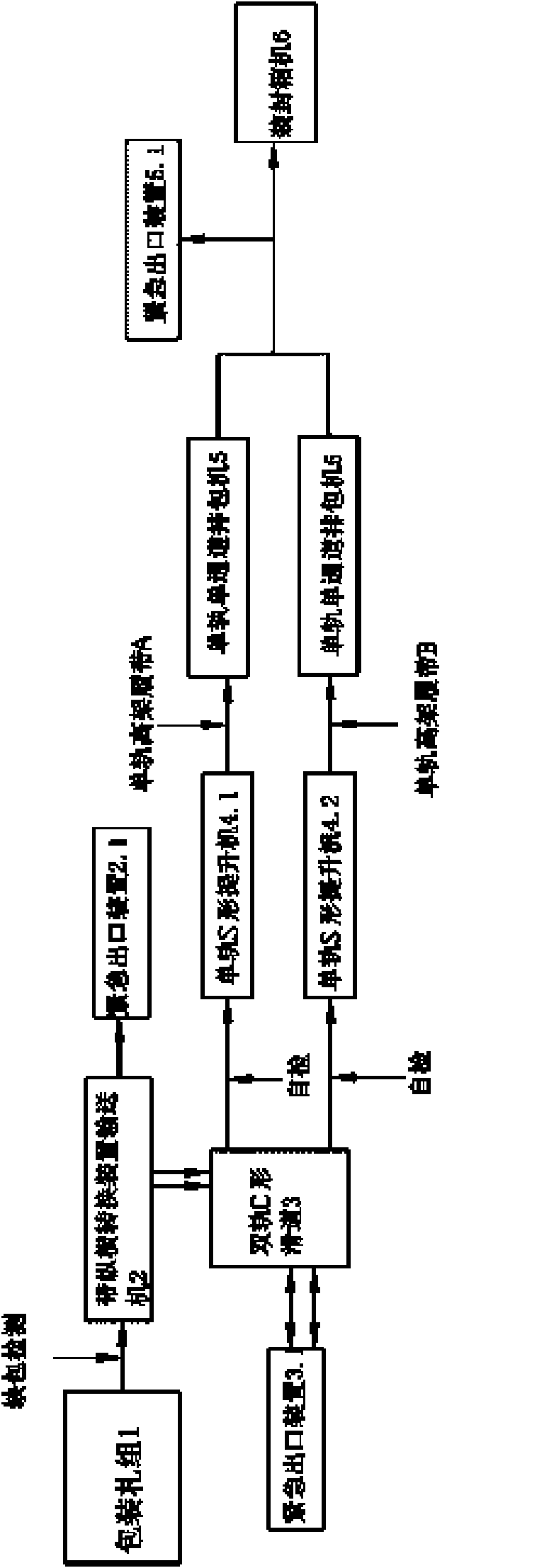

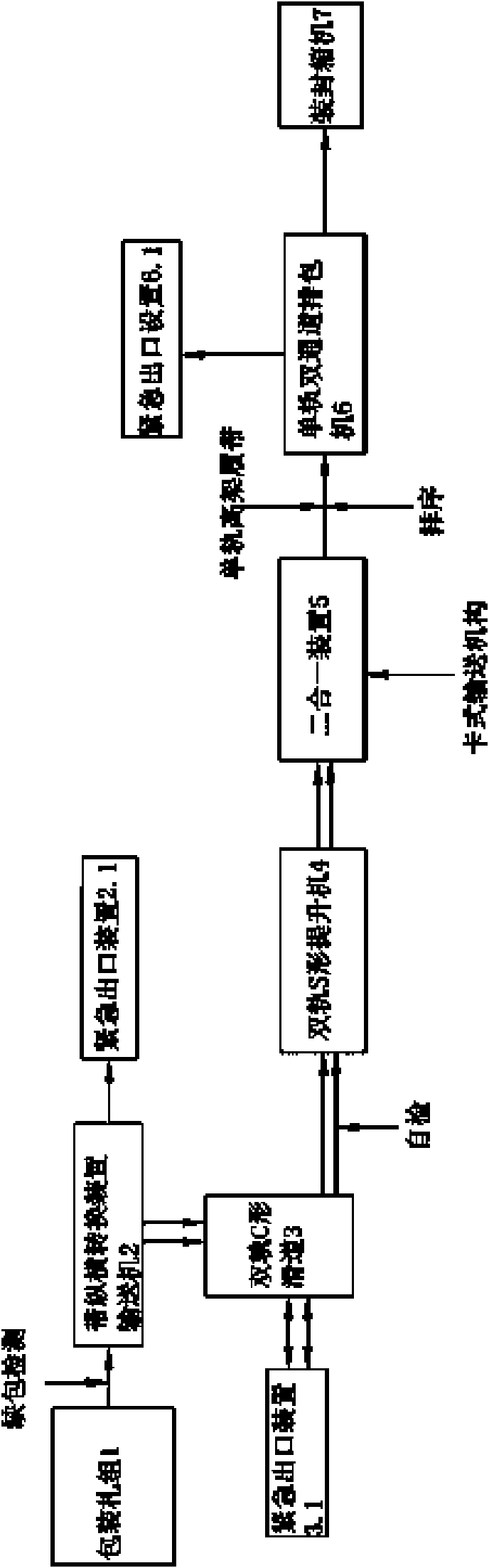

[0053] A cigarette delivery system, please refer to figure 2, which includes: a packaging unit (1), a lack of package detection, a conveyor with a vertical and horizontal conversion device (2), a cigarette emergency exit device (2.1), a double-track C-shaped slideway (3), a cigarette emergency exit device (3.1), a double-track S-shaped hoist (4), a two-in-one device (5), a monorail elevated crawler, a monorail dual-channel charter machine (6), a cigarette emergency exit device (6.1), a package Box machine (7). The packaging unit (1) is used for continuously delivering disordered cigarette rods. The packet missing detection is used to detect whether the output cigarettes are missing a packet. The conveyor (2) with a vertical and horizontal conversion device is connected to the packaging unit (1), and is used to convert the disordered cigarettes continuously conveyed by the outlet of the packaging unit (1) into a group of two cigarettes, and convert them horizontally into ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com