Novel magnetic liner plate of ball mill

A magnetic lining plate and ball mill technology, applied in grain processing and other directions, can solve the problem of insignificant economic effect, and achieve the effect of good non-magnetic conductivity, reasonable structure design and impact mitigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

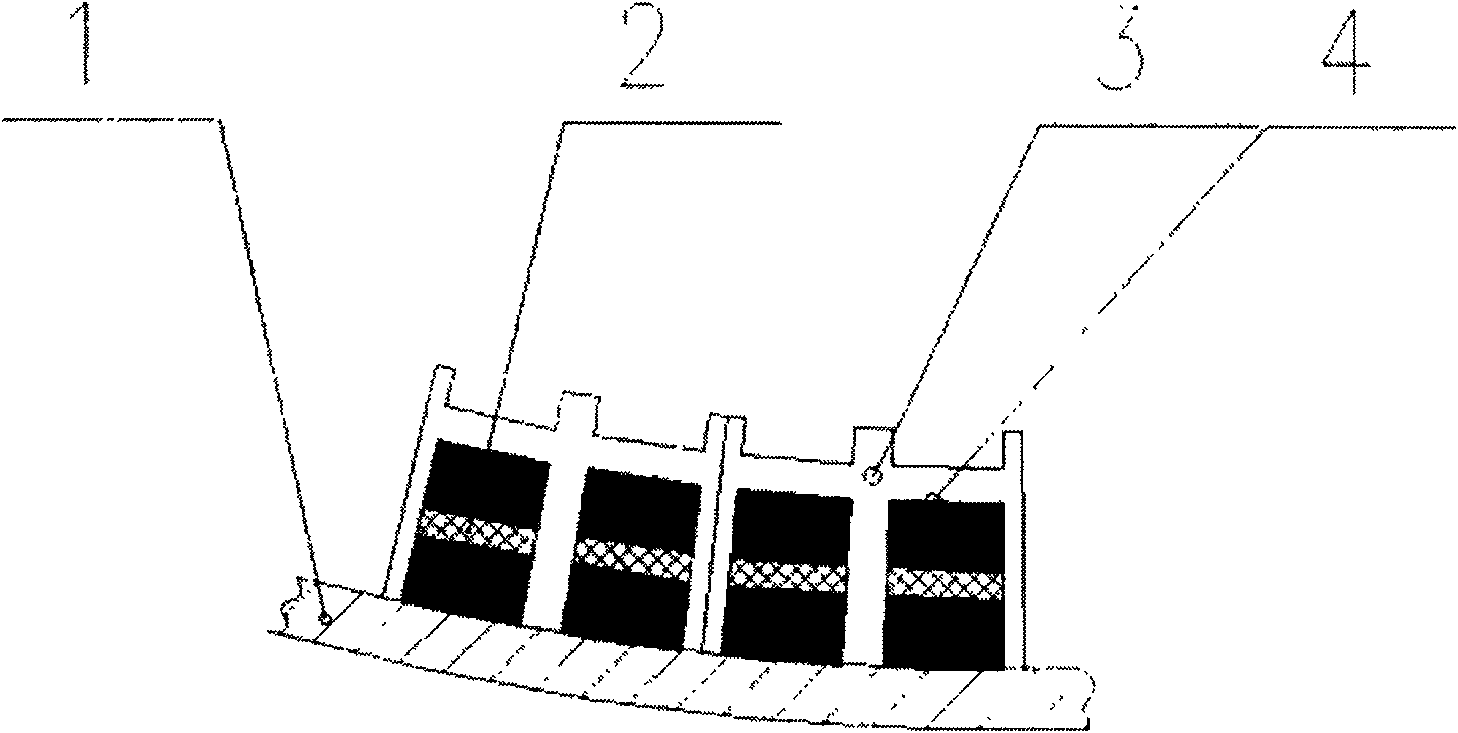

[0014] A new type of ball mill magnetic liner, such as figure 1 As shown, it includes a base 1 , a wear-resistant lining 3 , a composite magnetic pole set 2 and an adhesive 4 . A wear-resistant liner 3 is set on the inner wall of the base body 1. The wear-resistant liner 3 is made of high-strength and high-wear-resistant cast steel to protect the magnetic pole group. The percentage content of each component in the wear-resistant liner 3 is: C: 0.7%~0.9%, Mn: 14%~16%, Cr: 3.95%~4.05%, Si≤1.0%, S≤0.03%, P≤0.06%, and the rest is Fe. There is a cavity inside the wear-resistant lining plate 3, and the composite magnetic pole group 2 is bonded in the cavity of the wear-resistant lining plate 3 through an adhesive 4. Good shock absorption performance, etc., can effectively deal with extreme industrial and mining, and protect the magnetic pole group from oxidation. The high elastic performance of the adhesive 4 also reduces the impact and vibration of the material and grinding medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com