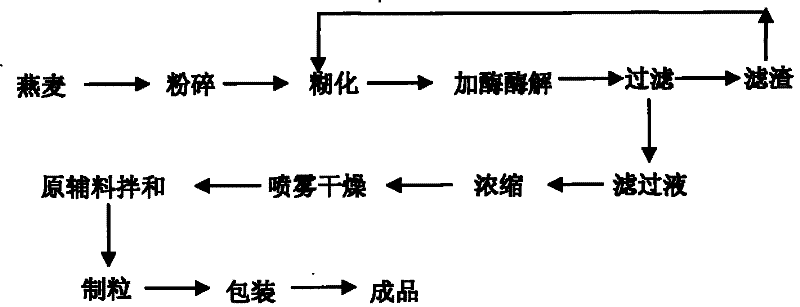

Method for producing oat solid beverage

A technology of solid beverage and production method, which is applied in the direction of food science, etc., can solve the problem of no oat beverage, etc., and achieve the effect of fine taste, rich nutrition and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) 9kg of oats, crushed to 60 mesh.

[0022] (2) Add 45kg of water to the extraction tank, start stirring, add oat flour, and turn on steam heating.

[0023] (3) Add 5.4ml of high-temperature-resistant amylase (liquid high-temperature-resistant amylase, Shandong Zaozhuang Jienuo Bioenzyme Co., Ltd., activity 20,000 U / ml), and keep for 40 minutes after boiling.

[0024] (4) Reduce the temperature of the feed liquid. When the temperature reaches 60°C, add 0.27 g of pectinase (Tianjin Lihua Enzyme Technology Co., Ltd., refined pectinase PC-3 type, activity 2 to 30,000 U / g ).

[0025] (5) Continuously centrifugally filter the feed liquid while it is hot, the centrifugal speed is 2800rpm, the filter aperture of the non-woven filter bag is 1-600um, and filter to obtain 9kg of primary residue (wet) and 40kg of primary filtrate.

[0026] (6) Put the primary residue in an extraction tank, add 40 kg of water, stir for 10 minutes, and then perform centrifugal filtration to obta...

Embodiment 2

[0031] Technological process is with embodiment 1.

[0032] Step (1): 9 kg of oats are pulverized to 40 mesh.

[0033] Step (2): add water 27kg water.

[0034] Step (3): Add 2.25ml of high-temperature-resistant amylase, and keep for 60 minutes after boiling.

[0035] Step (4): The temperature is lowered to 45° C., and 0.9 g of pectinase is added.

[0036] Step (5): Obtain 10 kg of primary residue (wet) and 22 kg of primary filtrate.

[0037] Step (6): add water 10kg water.

[0038] Step (9): 4.6 kg of oat beverage powder obtained by spray drying was mixed with 1.15 kg of fruit juice powder, and granulated, the granulation pressure was 3MPa, the granulation frequency was 40HZ, and the particle size range was 0.3mm. .

Embodiment 3

[0040] Technological process is with embodiment 1.

[0041] Step (1): crush the oats to 80 mesh.

[0042] Step (2): add water 135kg water.

[0043] Step (3): Add 9ml of high-temperature-resistant amylase, and keep for 60 minutes after boiling.

[0044] Step (4): The temperature is lowered to 55° C., and 5.4 g of pectinase is added.

[0045] Step (5): Obtain 7.5 kg of primary residue (wet) and 135 kg of primary filtrate.

[0046] Step (6): add water 15kg water.

[0047] Step (9): 5.6 kg of oat beverage powder obtained by spray drying was mixed with 2 kg of almond powder, and granulated, the granulation pressure was 3 MPa, the granulation frequency was 20 HZ, and the particle size range was 1.0 mm. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com