Online monitoring method of multipoint earthing of clamping piece of transformer

A technology of transformer clamping and multi-point grounding, which is applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of disappearing grounding points, inaccurate data, and reducing economic benefits, etc., and achieve the effect of protecting transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

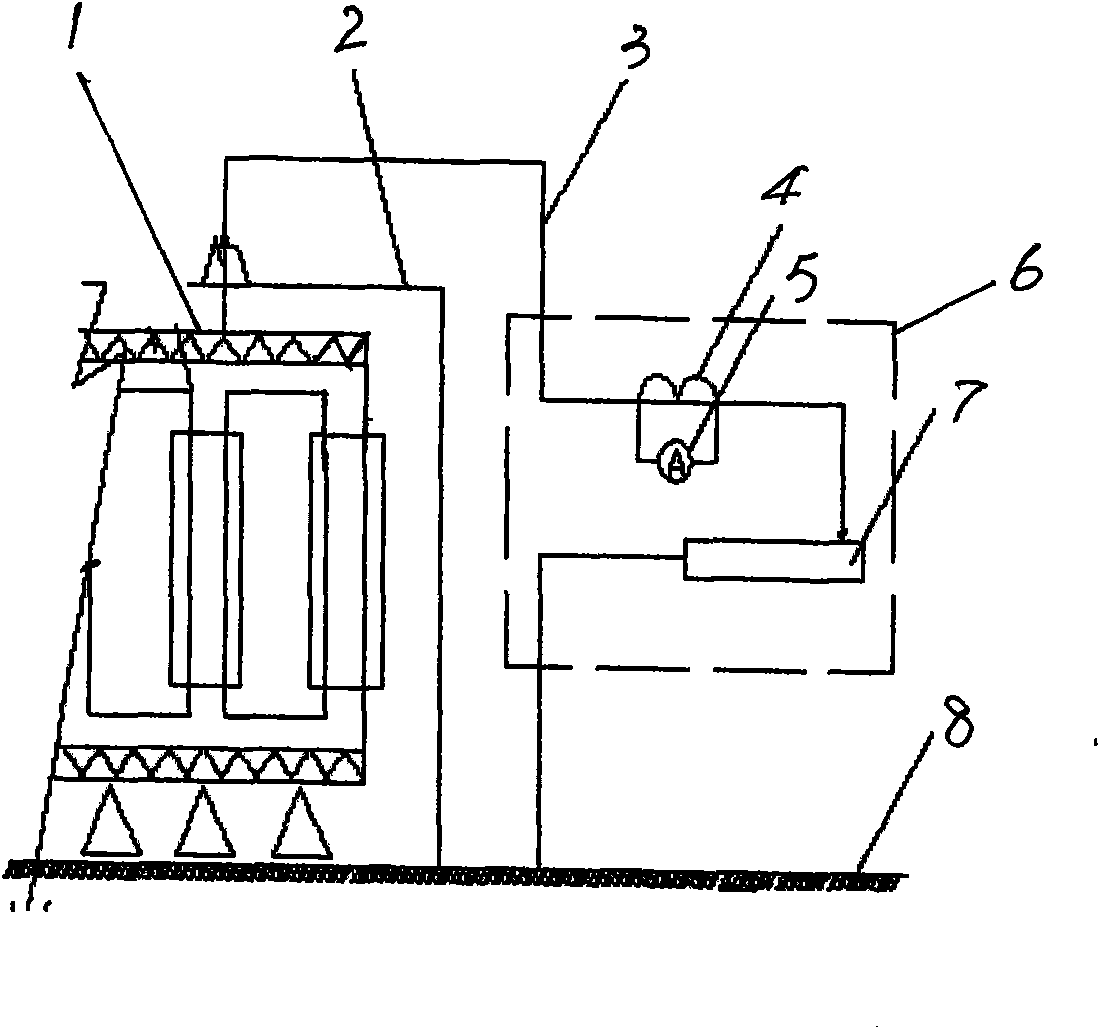

[0009] A device is connected in series in the clamp ground wire 3 of the transformer 2. As shown in the attached figure, the device is composed of a current transformer 4, an ammeter 5, an adjustable resistor 7 and a full metal casing 6. The current transformer 4 has a current ratio of 1. / 1, the precision is 0.5, the secondary side of the current transformer 4 is connected in series with an ammeter 5 with a double-layer scale, the first scale is 0-300mA, the precision is 0.5, the second scale is 0.3A-30A, The precision is 1.5, the range of the ammeter 5 can be switched automatically, and whether to switch is determined by the indicator light on the same layer, or the ammeter with digital display is adopted; the adjustable resistor 7 connected in series on the primary side of the ammeter 5 has a resistance value of 150Ω-- 10000Ω; when multi-point grounding occurs, the grounding current flowing through the transformer clamp 1 will exceed 100mA, adjust the adjustable resistor 7 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com