Vertical multi-drive series connection blade shutter type desulfuration baffle door

A shutter-type, multi-drive technology, applied in combustion product treatment, combustion method, exhaust gas device and other directions, can solve problems such as inability to operate, and achieve the effect of avoiding installation location restrictions and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the example in the accompanying drawing:

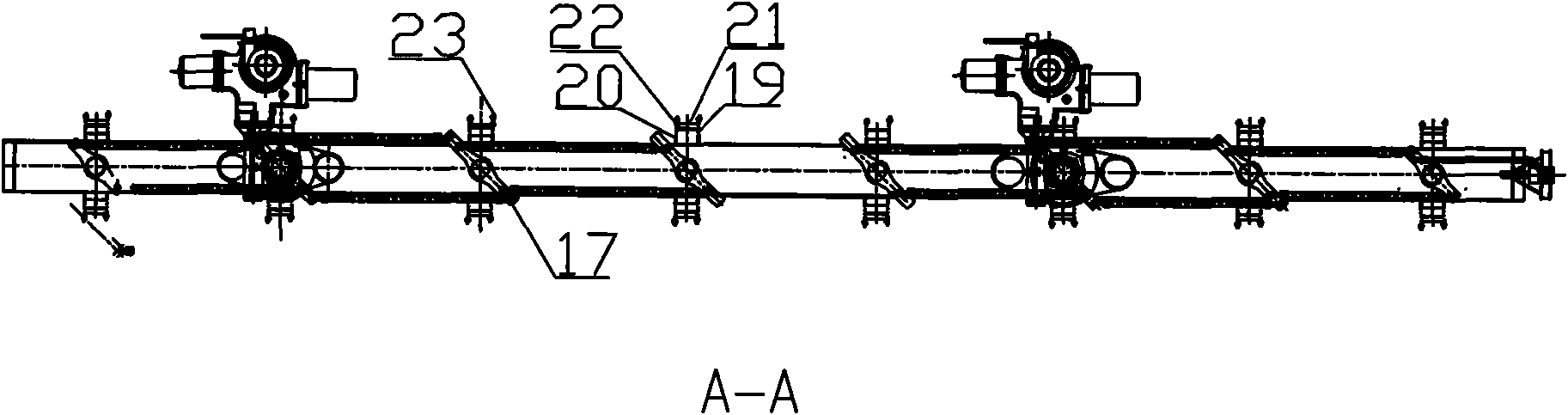

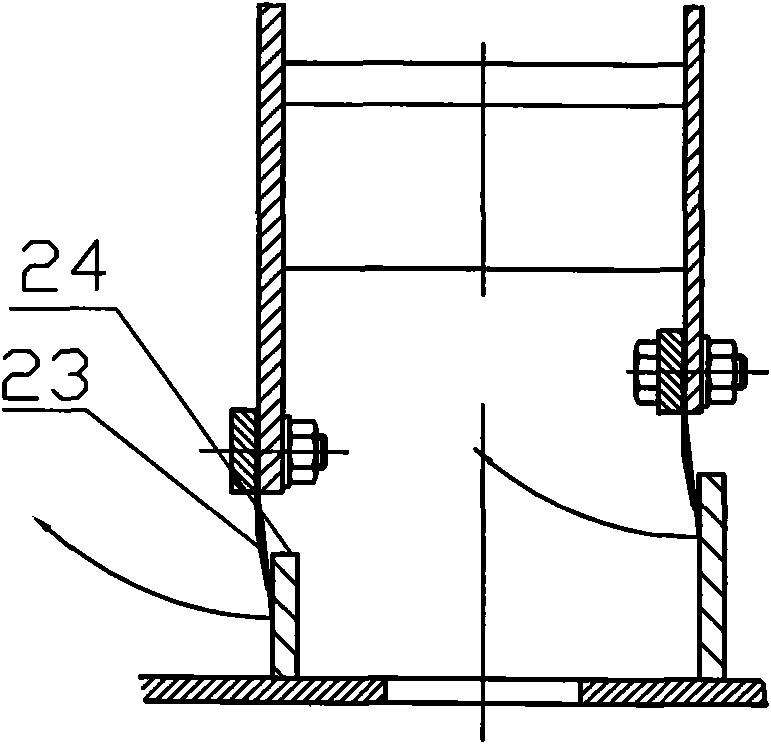

[0015] Such as Figure 1 ~ Figure 4 As shown, it includes limit switch 1, frame 2, electric actuator 3, upper shaft 4, alloy sleeve 5, shaft seal device 6, sealing air inlet butterfly valve 7, spherical roller bearing assembly 8, blade 9, sealing inlet Tube 10, pressure measuring tube 11, lower shaft 12, bearing bracket 13, intermediate connecting sleeve shaft 15, actuator bracket 16, crank 17, connecting rod 18, blade upper panel piece 19, blade lower panel piece 20, special-shaped groove 21, Middle truss 22, sealing sheet 23, frame sealing edge plate 24, etc.

[0016] The present invention adopts the uniform installation of several rotating shafts arranged longitudinally parallel to each other on the frame 2, and the blade 9 that can rotate around the rotating shaft is installed on each rotating shaft. A sealing device 6 is provided at the junction be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com