Sealing device

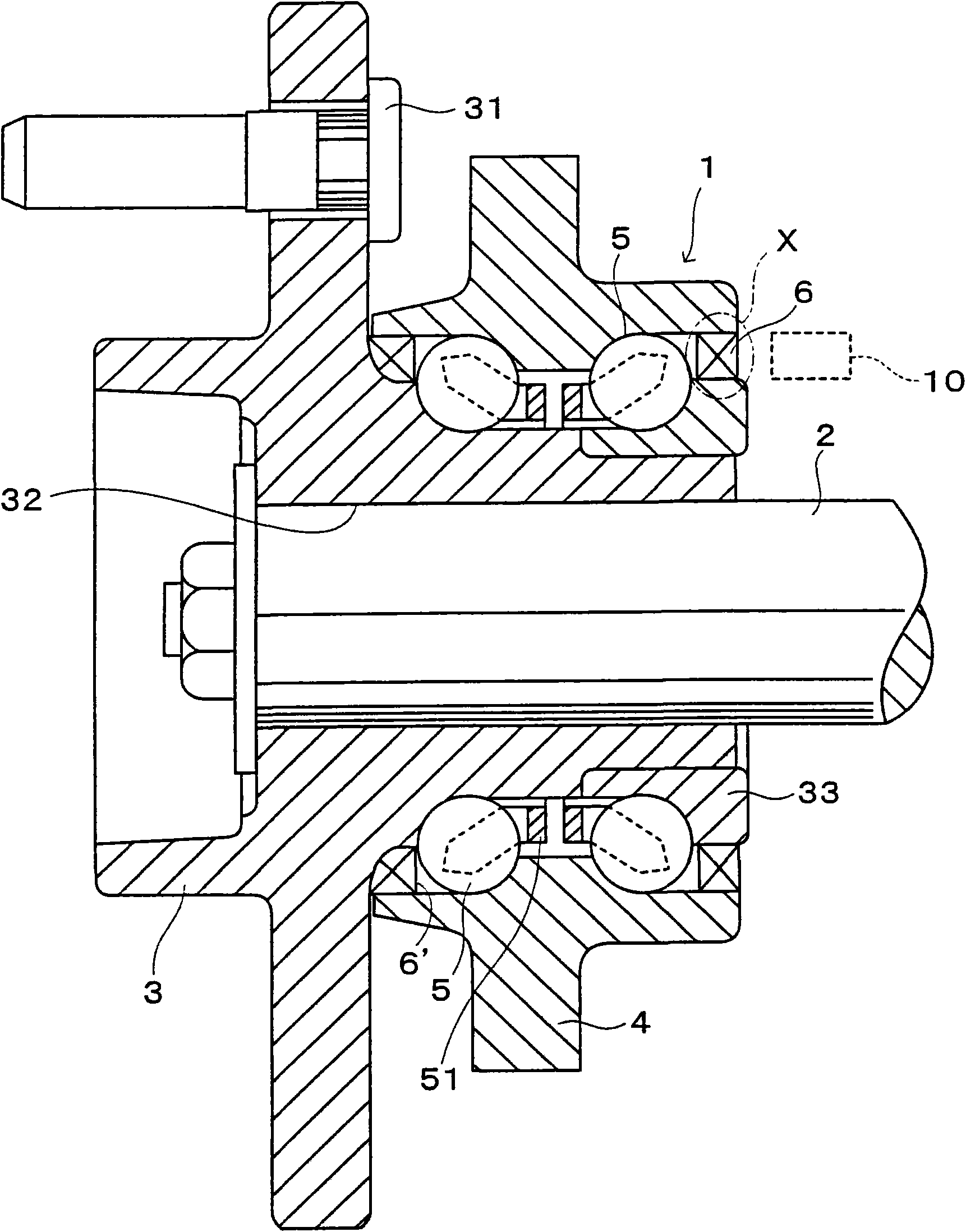

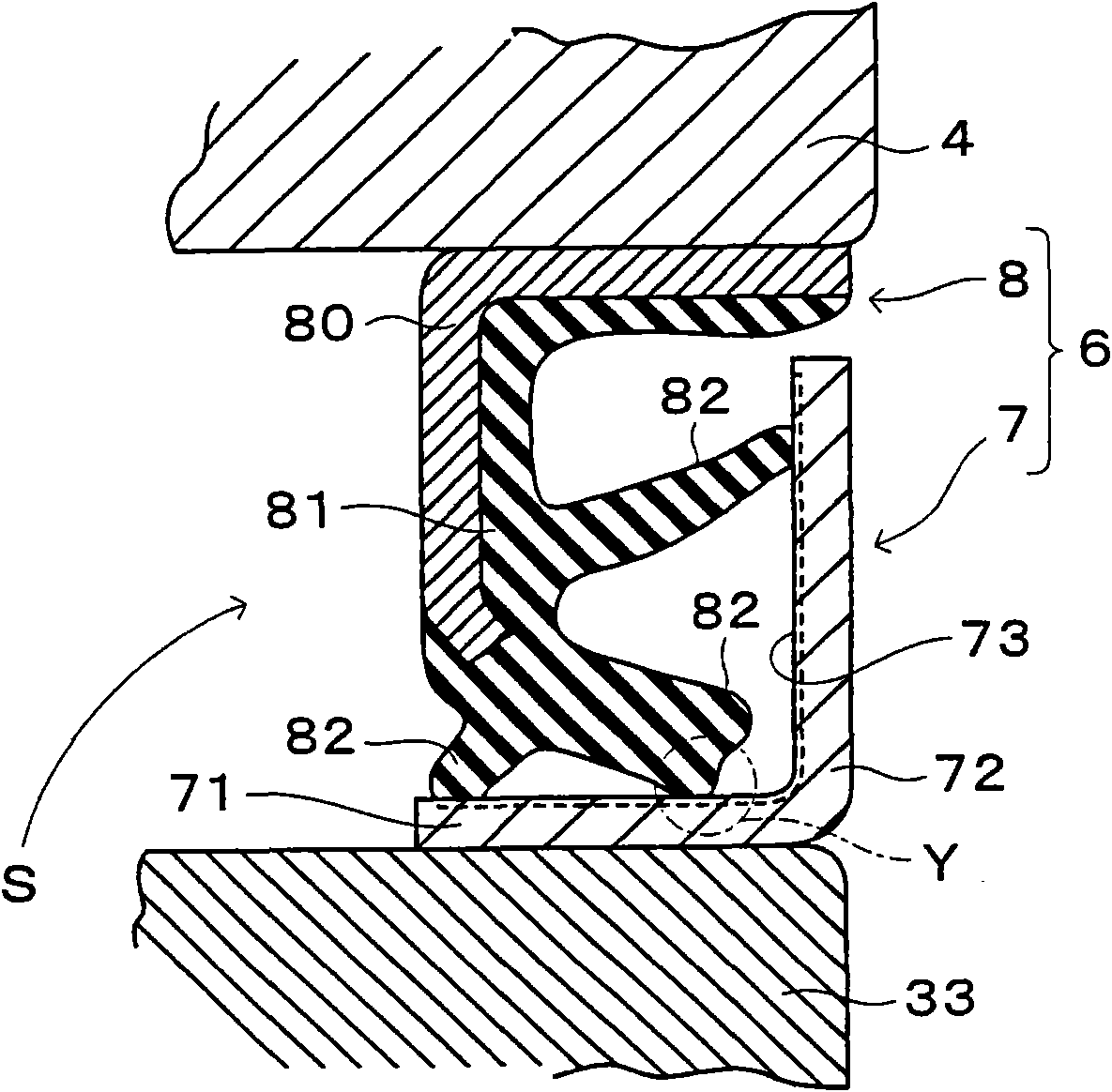

A technology of sealing device and sealing lip, which is applied in the directions of engine sealing, bearing assembly, transportation and packaging, etc., which can solve the problems such as the bad influence of the sealing lip sealing device, the effect of not showing the effect of reducing the rotational torque, etc., and achieve low fuel consumption The effect of realizing long life and realizing the heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

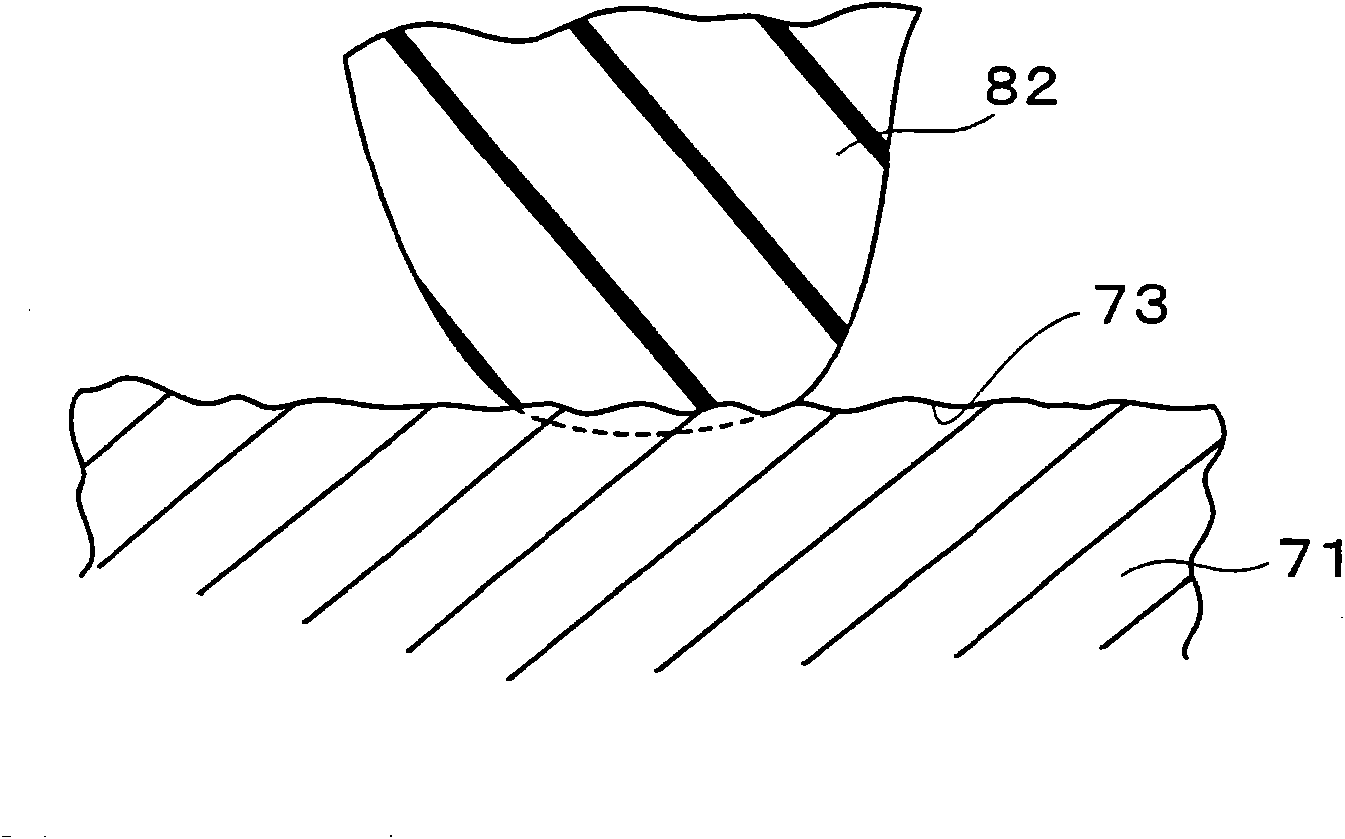

[0080] The metal material of SUS430 was used to prepare the hanging rings which form sample A - sample H.

[0081] Sample A is a suspension ring formed by rolling a steel plate, and is a sample without surface processing. Sample B is a sample obtained by cutting the metal material described above to form a suspension ring. Sample C is a sample in which a suspending ring is formed of the above-mentioned metal material, and the sliding contact surface with the seal lip is subjected to surface processing by the above-mentioned concave-convex transfer processing. Samples D to H are samples in which the surface of the sliding contact surface with the seal lip was subjected to surface processing by shot peening. The shot peening treatment of sample D to sample H is performed by spraying and colliding tiny rigid particles of steel balls with a diameter of 40 to 200 μm at a jet velocity of 100 m / sec or more as described above. The tiny rigid particles on the surface are removed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com