Preparation method of calcined diatomite flatting agent

A technology for calcining diatomite and matting agent, which is applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

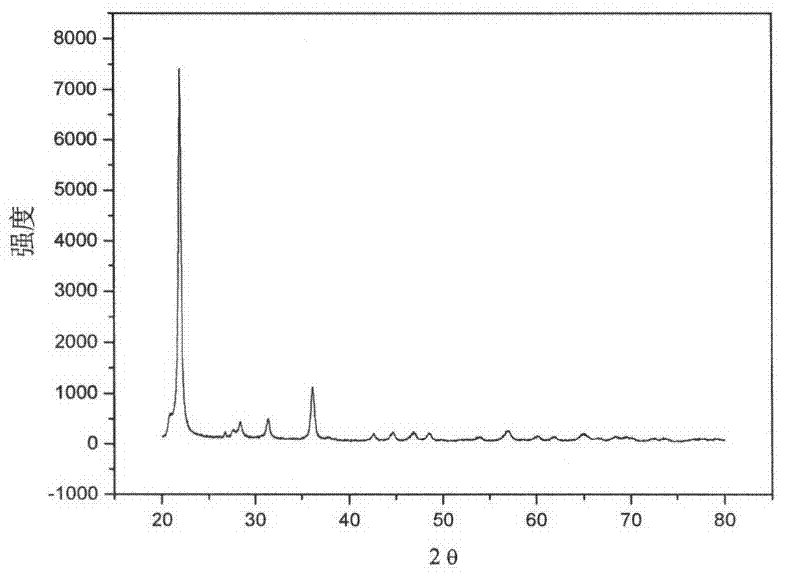

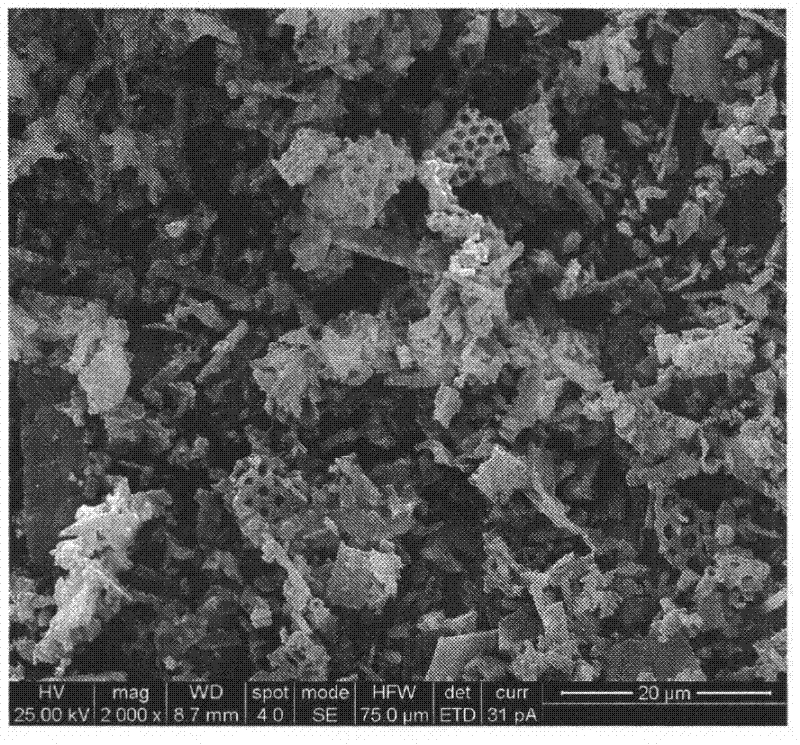

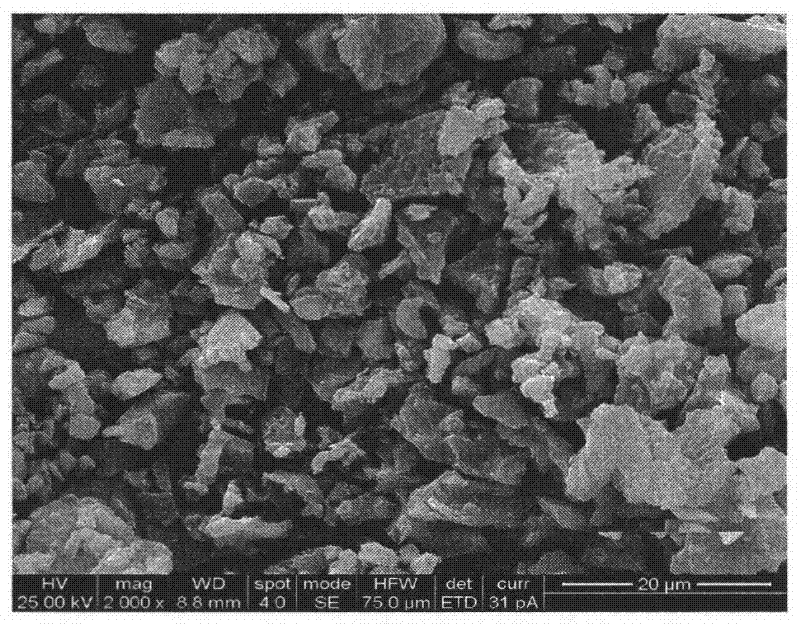

[0019] Example 1: Add 2wt% NaCl and 6wt% starch (diatomaceous earth is 100%) to diatomite, calcined at 850°C for 2 hours, and naturally cool down to obtain calcined material, which is air-jet crushed and gravity classified , named Y-1. Use styrene-acrylic emulsion paint, do a group of blank experiment, measure the coating glossiness that the incident angle is 20 °, 60 ° and 85 ° are respectively 2.6, 5.7 and 8.9; Sample Y-1 (accounting for 4wt% of coating weight ) (as shown in Table 1) was added in the above-mentioned styrene-acrylic emulsion paint, and the paint was painted according to the normal construction procedure, and the recorded incident angle was 20 °, and the coating gloss of 60 ° and 85 ° was respectively 1.3, 2.8 and 3.1, The glossiness of 60° and 85° is very close, and the extinction rate is 51% and 65% respectively.

Embodiment 2

[0020] Example 2: Add 3wt% NaCl and 7wt% starch (100% diatomaceous earth) to diatomite, calcined at 900°C for 2.5 hours, and naturally lower the temperature to obtain calcined material, which is air-flow pulverized and flotation Graded, designated Y-2. Use styrene-acrylic emulsion paint, do a group of blank experiments, measure that the coating glossiness of 20 °, 60 ° and 85 ° is respectively 2.6, 5.7 and 8.9 at incident angle; Sample Y-2 (accounting for 4wt% of coating weight ) (as shown in Table 1) was added in the above-mentioned styrene-acrylic emulsion paint, and the paint was painted according to the normal construction procedure, and the recorded incident angle was 20 °, and the coating gloss of 60 ° and 85 ° was respectively 1.3, 2.7 and 2.8, When the incident angle is 60° and 85°, the extinction rate is 53% and 68%, respectively.

Embodiment 3

[0021] Example 3: Add 4wt% NaCl and 8wt% starch (100% diatomaceous earth) to diatomite, calcined at 950°C for 3 hours, and naturally lower the temperature to obtain calcined material, which is jet-pulverized and centrifugally classified , named Y-3. Use pure acrylic emulsion paint, do a group of blank experiment, measure that incident angle is 20 °, the coating glossiness of 60 ° and 85 ° is respectively 2.6, 5.7 and 8.9; Sample Y-3 (accounting for 4wt% of coating weight ) (as shown in Table 1) was added in the above-mentioned pure acrylic emulsion paint, and the paint was painted according to the normal construction procedure, and the recorded incident angle was 20 °, and the coating gloss of 60 ° and 85 ° was respectively 1.3, 2.7 and 3.0, When the incident angle is 60° and 85°, the extinction rate is 53% and 66%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com