Method for preparing potassium nitrate by means of double decomposition

A metathesis method and potassium nitrate technology, which is applied in the field of potassium nitrate production by the metathesis method, can solve the problems of failing to meet the quality standard requirements of high-quality potassium nitrate, the product failing to meet the quality standard requirements, and no recombination reaction. The effect of high content, reducing process make-up water, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

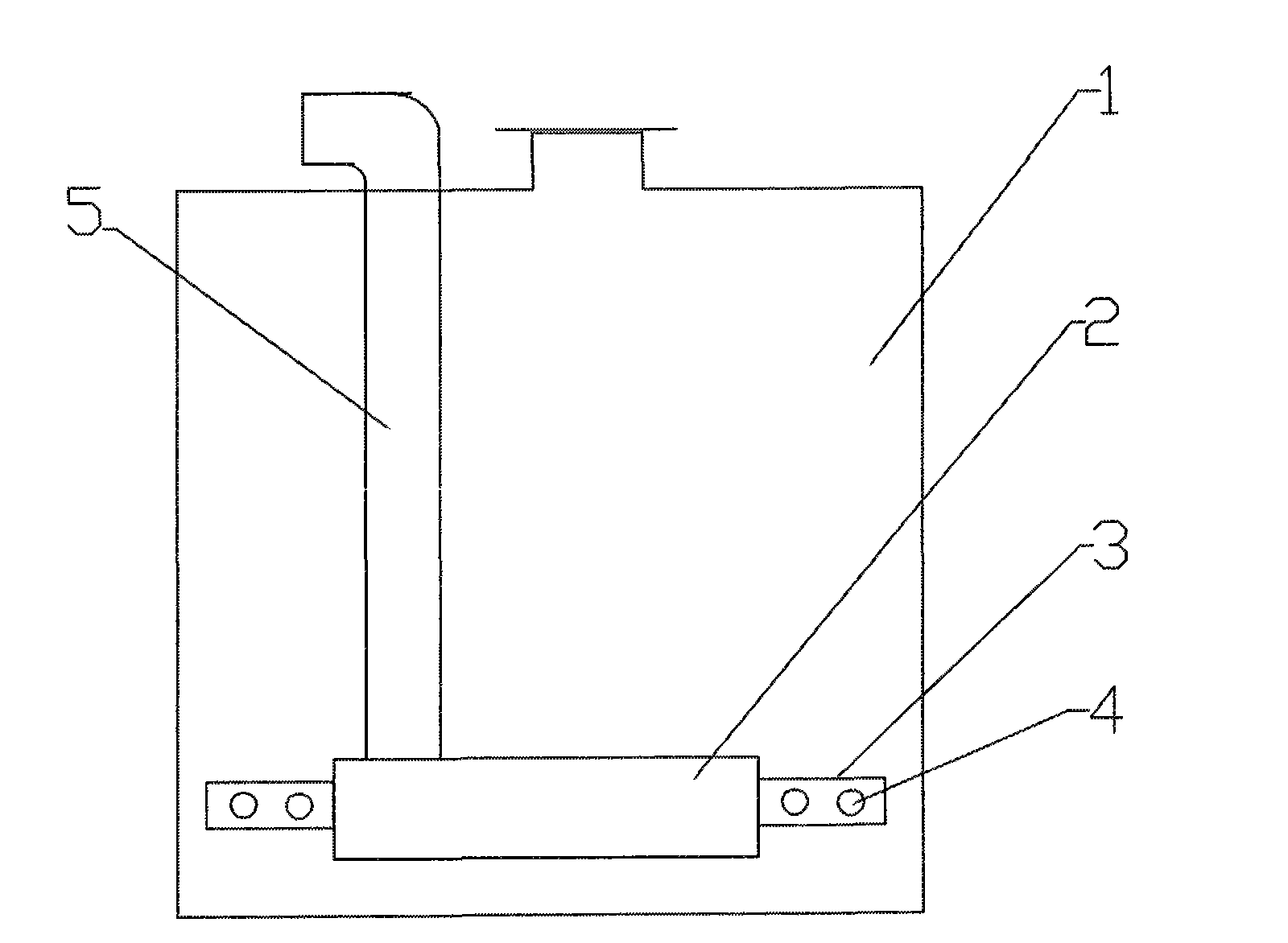

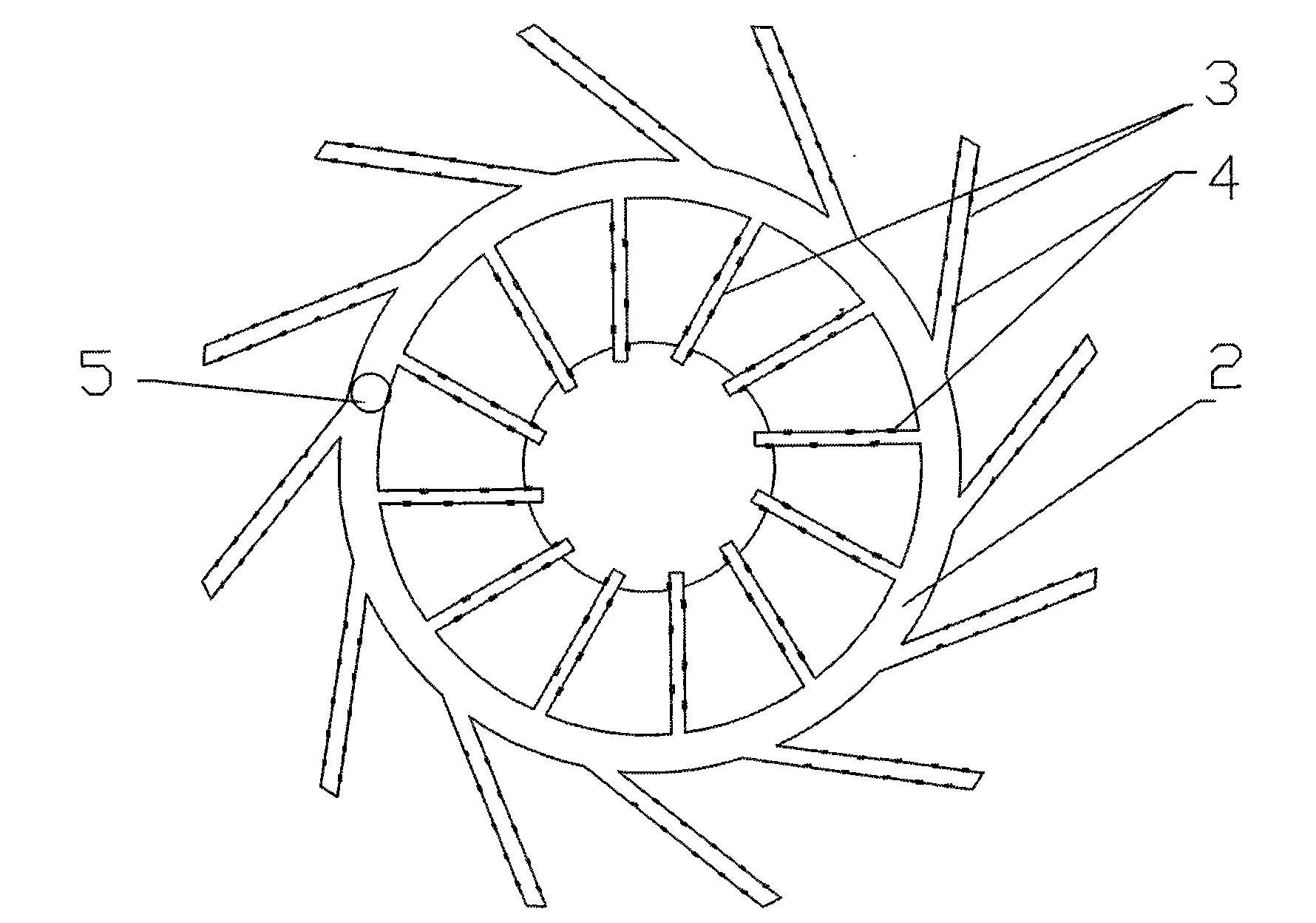

Image

Examples

Embodiment 1

[0034] (1) When batching for the first time, add appropriate amount of water, potassium chloride and ammonium nitrate to the reaction vessel, heat up to the temperature of the solution to 85-95°C, and control the concentration of Cl in the solution. - The concentration is 14~19% and NH 4 + The concentration is 6~6.9%; (2) KNO 3 Semi-finished product crystallization: When the reaction solution meets the above concentration requirements, it is placed in a cooling crystallizer to cool down to 0-25°C, so that the semi-finished product KNO 3 Crystallization; (3) cooling and crystallization solution filtration, filtrate (mother liquor I) is discharged to liquid storage tank, KNO 3 Crystallization is washed with water to make the solid KNO 3 Cl in - The mass fraction is 1-2%; NH 4 + The mass fraction is 1 to 3%, and the flushing liquid is discharged to the liquid storage tank; (4) semi-finished KNO 3 Crystal recombination in a metathesis setup: the KNO 3 Put the crystal into ...

Embodiment 2

[0035] The production method of embodiment 2 and embodiment 1 and process parameter and metathesis device are basically the same, and difference is stated as follows, (1) drop into reaction material in reaction vessel and react, control the Cl in the solution - The concentration is 14~15.8%, NH 4 + The concentration is 6-8%, and the temperature of the reaction solution is 95°C; (2) KNO 3 Cl in semi-finished crystal - The mass fraction is 1~1.5%, NH 4 + Mass fraction 1~1.5%; (3) KNO 3 When the crystal rejoins, control the concentration of the solution to 44-46Be; cool the crystallizer to 5-28°C to make KNO 3 The product crystallizes out; (4) NH 4 The Cl preparation solution is concentrated to a concentration of 33-37Be, and the KNO produced by the above process steps 3 The products have been sampled and tested by the national authoritative organization, and can meet or exceed the quality requirements of the national high-quality products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com