Garbage compressor

A waste compressor and complete machine technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of reducing the utilization rate of equipment, workers' work efficiency, high installation height of vertical transfer stations, and high flow rate of hydraulic pump stations. Improve the efficiency of garbage transfer, shorten the time, and reduce the effect of installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

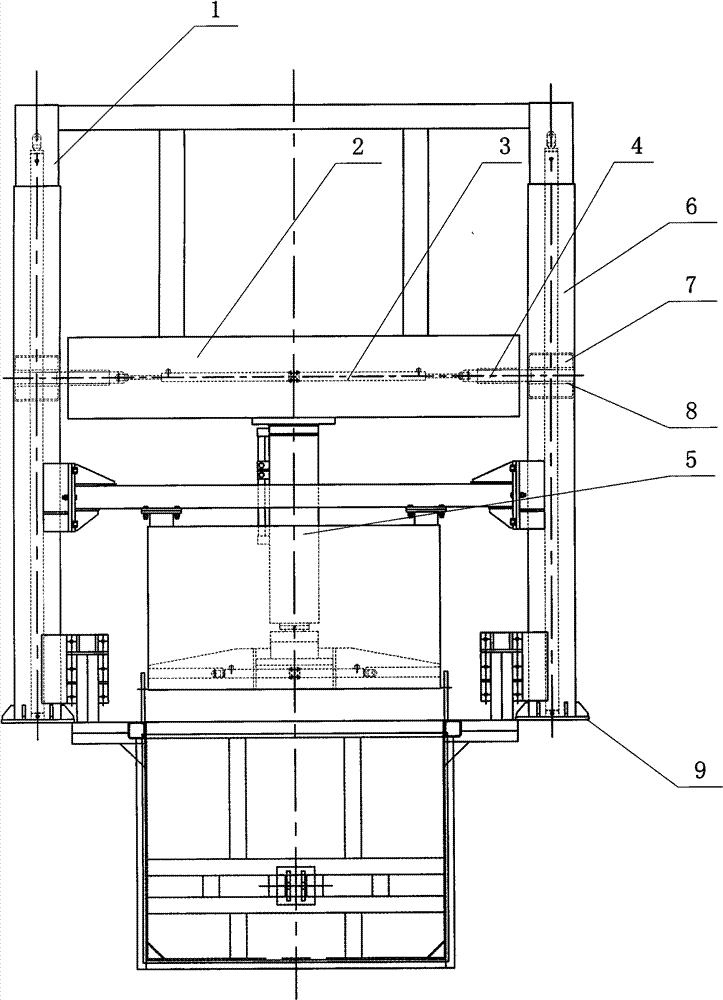

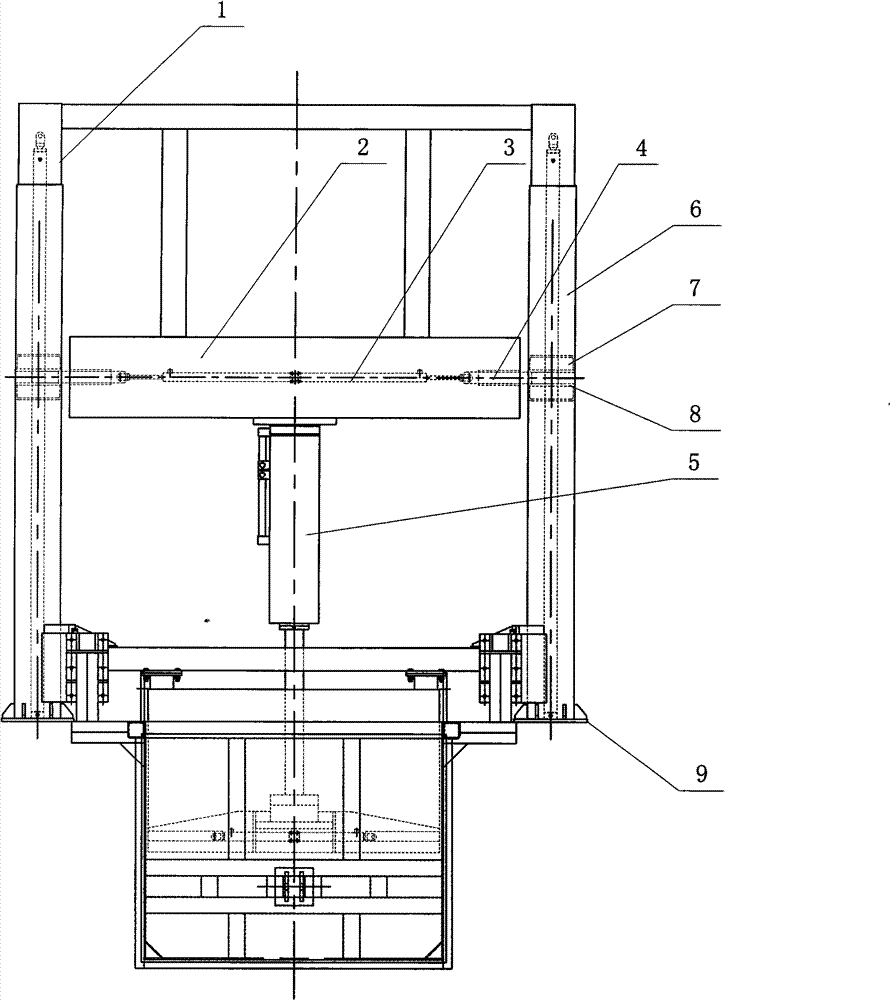

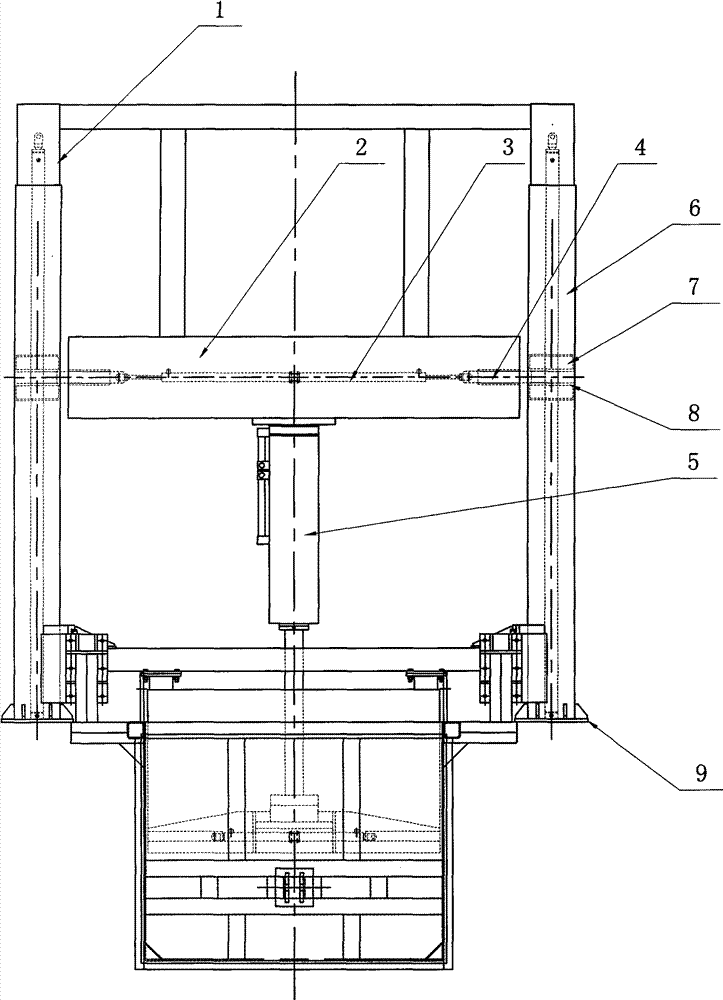

[0020] Further explain below in conjunction with accompanying drawing:

[0021] Such as Figure 1 to Figure 4 As shown, a telescopic garbage compressor includes a driving device for driving the whole machine and a telescopic main frame structure, which is characterized in that the main frame structure includes an outer guide column frame 6 arranged on the ground And the inner guide column 1 arranged inside, the transition box 2 arranged between the inner guide columns, the compression support beam 7 arranged between the outer guide columns, the main compression oil cylinder 5 is arranged between the transition box and the pressure head, and the transition box The longitudinal rod is connected with the crossbeam between the front and rear inner guide pillars; the lifting cylinder is arranged inside the inner guide pillar and connected with the bottom of the outer guide pillar by a hinge; the inner guide pillar 1 and the inner wall of the outer guide pillar frame 6 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com