Novel double-channel paper-feeding safety structure of paper shredder

A safe structure, dual-channel technology, applied in grain processing and other directions, can solve problems such as hidden dangers and unsmooth paper feeding, and achieve the effect of avoiding physical damage, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

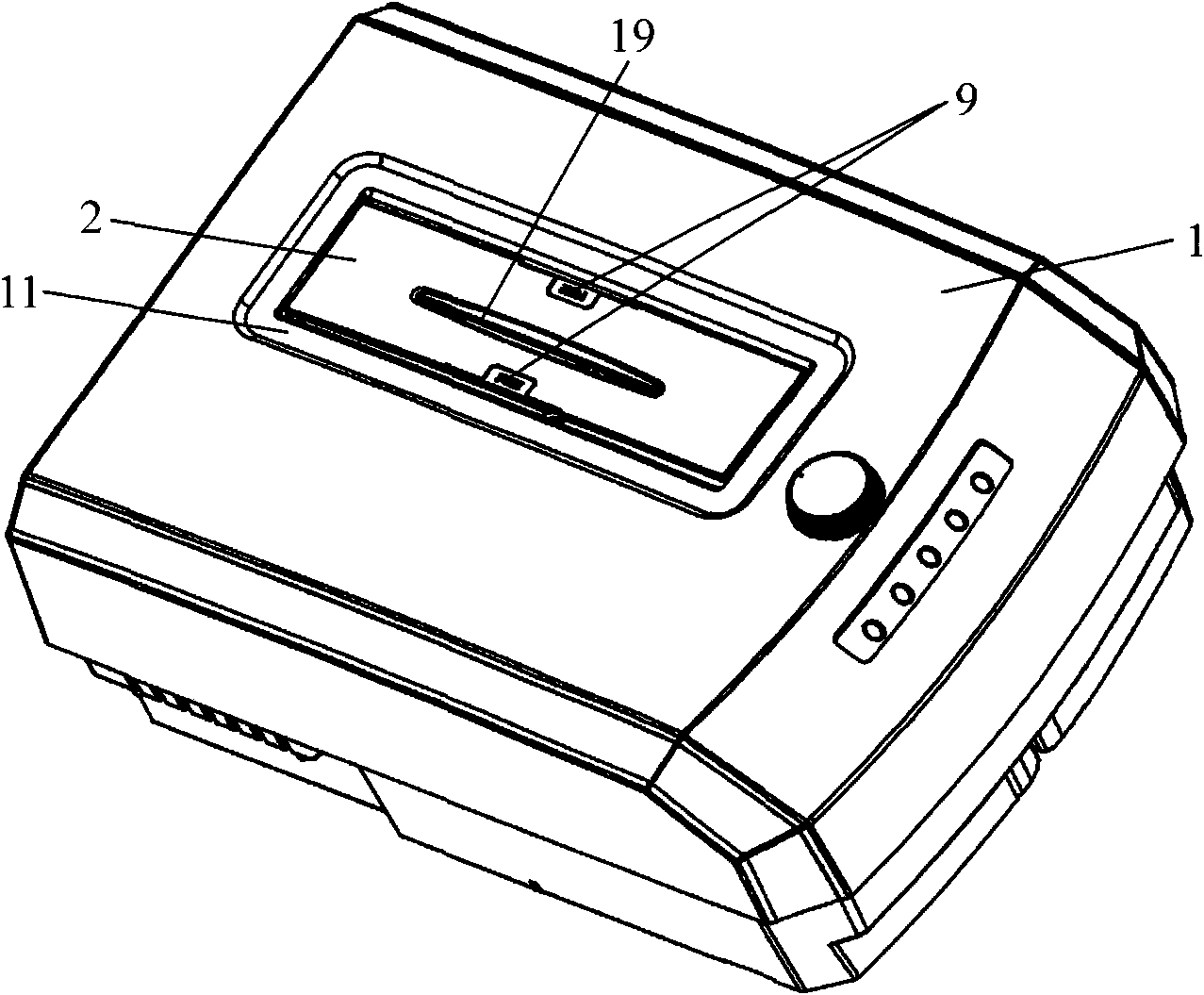

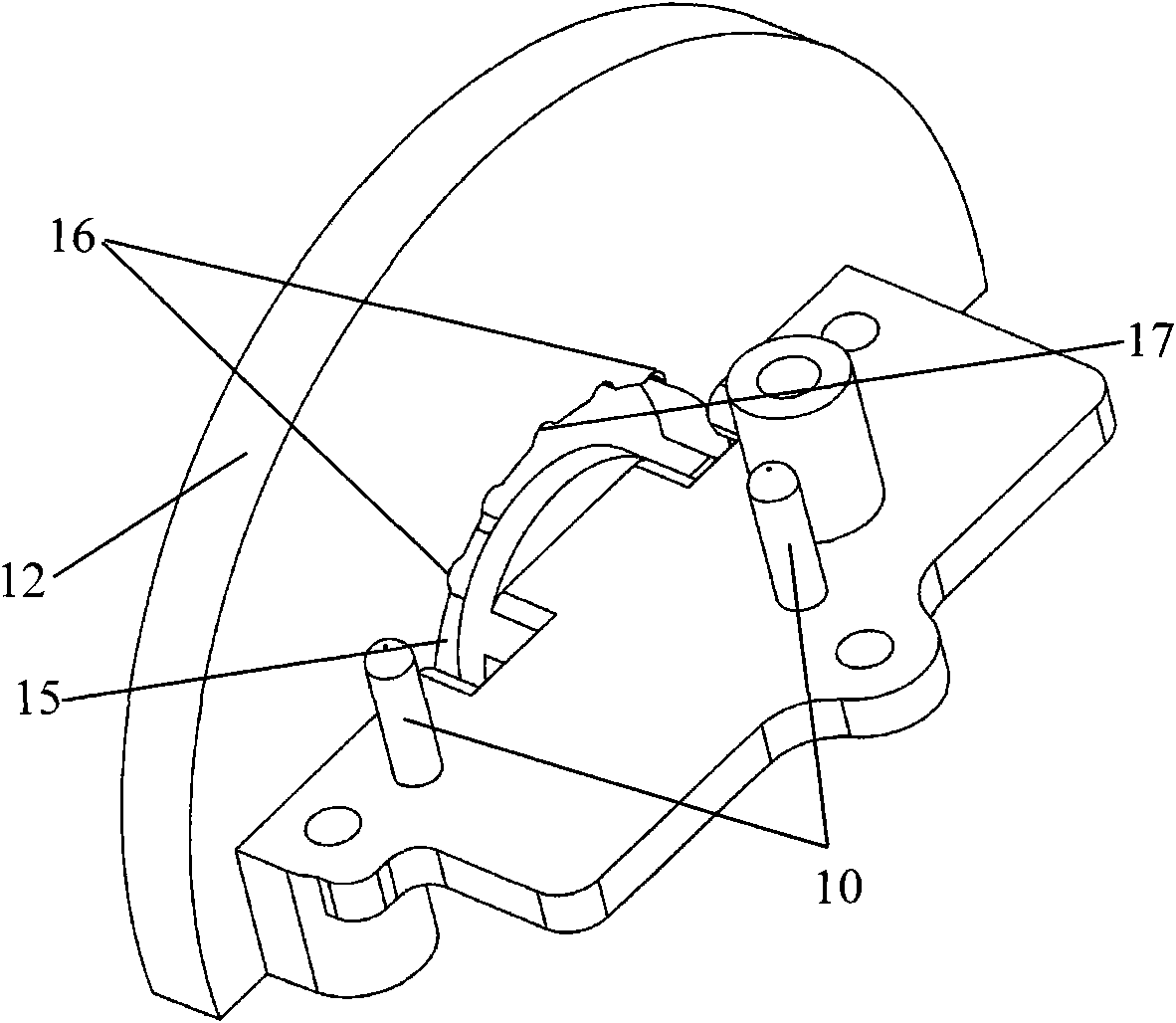

[0038] see Figure 1 to Figure 9 As shown, the novel shredder dual-channel paper-feeding safety structure of the present invention includes a paper shredder upper cover 1, and also includes a dual-channel paper-feeding safety cover 2 and a touch safety switch 3. The dual-channel paper-feeding safety cover 2 A touch part 21 is arranged on it, and the upper cover 1 of the paper shredder has a paper inlet 11 corresponding to the double-channel paper-in safety cover 2 and located above the shredder shaft of the shredder. The paper safety cover 2 is located in the paper inlet 11, the middle of both ends of the double-channel paper inlet safety cover 2 is rotatably connected to the upper cover 1 of the shredder, and the touch safety switch 3 is fixed on the shredder. The touch part 21 is arranged in the upper cover 1 of the paper machine and coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com